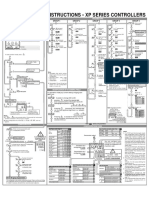

7 PROGRAMMING INSTRUCTIONS XP SERIES CONTROLLERS

FUNCTIONS MENU

DISPLAY

GROUP 1

GROUP 2

PARAMETERS GROUP 3

GROUP 4

275.8

275.8 4 50

Process variable during normal operation during Function value programmin g during normal Set point operation Function mnemonic

during programmin g

WpAss Enter correct Password

NO

GROUP 5

Wy2s.p Y2 Set point (see note 1)

300

Wp.b. Wt.i. Wt.d.

Proportional band 0.5999.9%

5:0

Wdy. WAp. h WAp. 1 Wt.y.

KEYS

Digit select Increment value

Wy3s.p y2Hy W y3Hy W

Y3 Set point (see note 1)

Integral time 0.0100.0 minutes

1:00

Minimum output resolution 0.1.10..0%

1 memory Ws.p. 1 point Set

st

10

OK

YES

Return to process variable display Straightly from configuration

300

Y2 Hysteresis 0.0110.00% span

5:0

0:50

Y3 Hysteresis 0.0110.00% span

Derivative time 0.010.00 minutes 1:00 (0.00 no effect)

Approach high .012 x Proportional Band 0:50 Approach low 0.12 x Proportional Band 0:50 Time for valve to fully open from fully closed 15600 seconds 60

Ws.p. 2 Ws.p. 3 Ws.p. 4

2nd memory Set point

20

3rd memory Set point

Ws.p.l.I Set point limit low

Beginning of the scale

30

4rd memory Set point

Enter Function

0:50

40

Slope up during

Ws.p.l.h Set point limit high

End of the scale 0...30 secs 0

To enter function mode, press

WsI. u transition of the Set point Wt.fil Time constant of 0.0120% span/min. the input filter 0:0 (see note 2) WsI. d

Slope down during transition of the Set point 0.0120% span/min. 0:0 (see note 2)

tune W

WIn.sh Input shiftdigit -5050

0

Run Auto - Tune function

Wpot.1 Calibrate position

Note: 1 Allowable Set point values depend upon the type of alarm configuration Deviation alarm : -300+300 Band alarm: 0300 Independent: on full scale 2 Parameters Y2 and Y3 will not appear if in the configuration code (I = 0 and L =0)

potentiometer The valve is driven fully closed

WA.par Protection level code (see note)

0000 ...2222 2222

Modify or view Parameters

W Conf

View Configuration code

Wpot.1 Calibrate minimum

WA.tu.

4250 X

7500 W Y Co

Start Configuration Procedure

Ws.p. t

Note: position of valve 1 The 4 memory set point will only be shown if configuration code N=0 If there is set point stored with a same value, the first in the Accept sequence is recall calibration point 2 If slope gradient = 0 there will be a step change Calibrate maximum position of valve

Type of tune available 0 No Tune available 1 Only Auto-Tune

Only for models with Serial communication option

View Target Set point

MODIFICATION OF A NUMERIC FIELD

It is possible to modify any numeric field by changing each digit in turn. Example: to change 250 to 260

Wpot.h

WAddr Device Number 063

0

Accept calibration point

Ws.C.b.r

Baud rate index 04 1

Baude Rate 0 9600 * 1 4800 2 2400 3 1200 600 4 * Only for B = 2 or 3

only for models with serial comms View instrument Device number 0 63

sCI W

pressing to select the required digit. Each successive press of this button moves the flashing digit one place to the left.

Note: Parameter protection 1st group 2nd group 3nd group 4nd group Parameter protection code A.par W

sCI

Note: 1 If

63

Toggle Serial Communication ON/OFF to write

Serial Communication status enabled to write

Pressing increments the selected digit (for the most significant digit there is a - between 9 and 0)

Ws.C.pa Parity 04 0

Parity Protoc. None 0 Ascon 1 Ascon Odd 2 Ascon Even None* 3 Modbus None* 4 Jbus * Only for B = 2 or 3

or is not pressed within 10 seconds the instrument will time-out back to the process variable.

2 If the configuration N=0 and

appear.

sl.u = sl.d = 0, sp.t will not

Pressing to accept the field or the field will be accepted automatically after the 10 seconds time-out.

Note: factory set parameters

2220 X

VIsable and modification 2 Visable but NO MODIFICATION 1 NOT VISABLE 0

CONFIGURATION

CONFIGURATION CODE

WpAss Enter correct password to start configuration process

NO

Input type, scale range (1) -200600C

RTD Pt100 IEC 751

E F

Conf.

-200600C -99.9...300,0C

!

Return to process variable display

Conf -99,9...300.0C

Thermocouple J Fe Cu 45%Ni IEC 584 Thermocouple L Fe-Const DIN 43710 Thermocouple K Cromel-Alumel IEC 584 Thermocouple S Pt10%RhPt IEC 584 Thermocouple R Pt13%RhPt IEC 584 4...20 mA 0...20 mA 0...1 Vdc 0...10 Vdc

OK

YES Entering the configuration process

if not configured at the power-up the main display will show: Straightly

0...600C Conf. within 0...600C 0 ...600C Conf. Conf. Conf. Conf. Conf. Conf. Conf. Conf. 0600C 0 ..1200C 0...1200C 0...1600C 0...1600C 0...1600C 0...1600C eng. units eng. units eng. units eng. units

WCon.1

Enter the first block of 4 configuration index codes - E, F, 5, H

9999 X

4 WCon.2 Enter the second blockL,ofM, N configuration codes I,

9999 W Y Co

0 0 1 1 2 2 3 3 4 4 5 5 6 6 7 7 7 7

0 2 0 2 0 2 0 2 0 2 0 2 0 2 4 5 6 7

Type of action and safety state Y1(2) Reverse Direct Reverse Safety Safety Safety Safety 0% 0% 100% (Yh) 100% (Yh)

Servomotor output

Direct

0 1 2 3

5

First block of 4 configuration code E,F,5,H Second block of 4 configuration code I,L,M,N

4250 X

You can configure your instrument just entering through the keyboard an 8 characters code

Wsc.d.d

Number of decimal places required 03 1

Type of Set point and control mode output Y3 Type of Set point and control mode output Y2 Disabled Deviation with startup inhibition Band Independent Active high Active low Active outside Active inside Active high Active low Active high Active low

7500 W Y Co

!

if at the power-up you will see 9999 -9999 that means the instrument IS NOT CONFIGURED

Wsc.1o Engineering range low value for user

100

configurable range Engineering range high value for user configurable range

Wsc.hi

To the 5th group of parameters

The configuration code shall be continuously shown. There is no time-out. Exiting the configuration process you will access straightly the 5th group of parameters to modify, if necessary, Set point limits, maximum power output etc.

Deviation Time programmable

0 1 2 3 4 5 6 7 8 9

Disabled Deviation with startup inhibition Band Independent Deviation Active high Active low Active outside Active inside Active high Active low Active high Active low

Loop - Break - Alarm Time programmable (3)

0 1 2 3 4 5 6 7 8 9 9

Type of Set point 1 Local + 4 stored Standard 1 Local and Remote 420 mA 1 Local and Remote 010 Vdc Time programmable (6) Retransmission output Y4 None (4) 420 mA Retransmission measurement X Retransmission Set point W

0 1 2 3

010Vdc Retransmission measurement X (5) Retransmission Set point W

0 1 2 4 5

Notes: 1 For Pt100 and thermocouple inputs with configurable scale, it advised to select significant and round figure scale ranges (-50150C, 0400C). The minimum span should not be less than 25% of the maximum range. Keep in mind that, within the selected range, it is possible to limit the setting interval of the Set point between the lower and upper value. For mA and Volts inputs, the beginning and end of scale values can be configured in engineering unit beetwen999 and 9999. The minimum scale span is 100 steps. The values can be expressed in units (xxxx), in tenths (xxx.x), hundredths (xx.xx), or thousandths (x.xxx). 2 The safety state is the value assumed by Y1 in case of failure in the control loop. Actually, it is the value defining the upper limit of Y1. 3 Only available with the programmable Set point option (D-1). Replaces the Loop-Break-Alarm function. 4 Excluding the retrasmission output option (C-0) implies selecting (M-0) in configuration. 5 Passing from 420 mA to 010V is obtained also by moving a jumper inside the instrument.(see chap. 4 pag. 11). 6 The programmable Set point option (D-1) implies selecting (N-3) in configuration.