0% found this document useful (0 votes)

828 views6 pagesMRP Reorder Point Planning

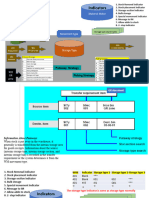

This document provides a simple example of running reorder point planning in SAP using 4 steps: 1) Create a material, 2) View current stock, 3) Run single item MRP, 4) Evaluate MRP results. The key is setting the material master to use MRP type V1 for manual reorder points and lot size HB for replenishing to maximum stock level. Running MRP should then create a purchase requisition to bring stock up to the maximum level.

Uploaded by

Ani MeniniCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

828 views6 pagesMRP Reorder Point Planning

This document provides a simple example of running reorder point planning in SAP using 4 steps: 1) Create a material, 2) View current stock, 3) Run single item MRP, 4) Evaluate MRP results. The key is setting the material master to use MRP type V1 for manual reorder points and lot size HB for replenishing to maximum stock level. Running MRP should then create a purchase requisition to bring stock up to the maximum level.

Uploaded by

Ani MeniniCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

/ 6