1

STEAM ENGINE GENERATOR CAPACITY CALCULATION

3.9.1

Normal Operation

3.9.1.1 Total Demand Load (KW)

= (1 x 1675.53) + (0.5 x 266.65)

3.9.1.2 Total Demand Load (KVAR)

= (1 x 1082.45) + (0.5 x 197.84)

3.9.1.3 Total Demand Load (KVA)

= (1 x 1997.99) + (0.5 x 332.04)

3.9.1.4 Total Peak Load (KW)

= (1 x 1675.53) + (0.5 x 266.65) + (0.1 x 933.26)

3.9.1.5 Total Peak Load (KVAR)

= (1 x 1082.45) + (0.5 x 197.84) + (0.1 x 572.34)

3.9.1.6 Total Peak Load (KVA)

= (1 x 1997.99) + (0.5 x 332.04) + (0.1 x 1094.95)

3.9.2

1808.86

KW

1181.36

KVAR

2164.01

KVA

1902.18

KW

1238.60

KVAR

2273.51

KVA

Data of the Largest Stand-by Motor

3.9.2.1 Motor Data

- Equipment No.

- Description

- Rated kW

- Rated Voltage

- Power Factor on Full Load

- Starting Power Factor

- Efficiency on Full Load

- Consumption kW

- Consumption kVAR

P-912 C

Cooling Water Recirculation Pump with motor

160.00 KW

380 V

0.85

0.25

0.926

145.79 KW

90.35 KVAR

3.9.2.2 Motor full load current ( IFL)

= ( ( 160.00 x 1000 ) / (0.93 x 0.85 ) ) / ( 1.73 x 380.00 )

3.9.2.3 Motor starting current ( Is) using DS starting type

= 0,33x650 % x 308.85 x 0.33

=

3.9.2.4 Motor starting capacity ( KVAs)

= ( 1.732 x 662.48 x 380.00) / 1000

=

3.9.2.5 The Load before starting

KWB = Total Demand Load (KW)

=

KVARB = Total Demand Load (KVAR)

=

KVAB = Total Demand Load (KVA)

=

3.9.2.6 The Load after starting

KW = Total Demand Load (KW) + KW motor

=

KVAR = Total Demand Load (KVAR) + KVAR motor

=

KVA

=

=308.85

662.48

436.03

KVA

1808.86

1181.36

2164.01

KW

KVAR

KVA

1954.64

1271.72

2331.93

KW

KVAR

KVA

�3.9.2.7 Required capacity for permissible voltage dip

KVA1 = ( 436.03+2164.01) x 0.17 x ( 1 - 0.15 ) / 0.15

=

2504.71 KVA

3.9.2.8 Required capacity for permissible overload during starting

KVA2 = ( V ( 1808.86 + 436.03 x 0.25 )2 + ( 1181.36 + 436.03 x 0.97 )2 / 1.50

=

1666.61 KVA

KW2

= ( 1808.86 + 436.03 x 0.25 ) / 1.10

=

1743.51 KW

2

SELECTION OF GENERATOR CAPACITY

2.1

2.1.1

STEAM ENGINE GENERATOR

The selected capacity of Steam turbine generator must be sufficient for each of the calculated value s

The maximum calculated capacity in above section for real and apparent power shall be the minimum

KW :

KW

1,954.64

KVA :

KVA

2,504.71

2.1.2

The selected capacity of Steam turbine generator shall be:

KW G :

KW

5,700

KVAG :

PF

:

2.1.3

2,000

0.80

KVA

Lagging

Conclusion of Steam Engine Generator Capacity

No.

1

2

3

4

Condition

Required Power

kW

Margin (%)

Normal Operation

1,808.86

68.27

Peak Load

1,902.18

66.63

Study of 150 kW Motor Starting (During Starting)

1,743.51

69.41

Study of 150 kW Motor Starting (After Starting)

1,954.64

65.71

According to the results of this study, it is further confirmed that the capacity of generator

is sufficient for normal operation of Bioethanol Plant

3

EMERGENCY DIESEL GENERATOR CALCULATION

4.9.1

Normal Operation

4.9.1.1 Essential Demand Load (KW)

= (1 x 0.00) + (0.5 x 0.00)

4.9.1.2 Essential Demand Load (KVAR)

= (1 x 0.00) + (0.5 x 0.00)

4.9.1.3 Essential Demand Load (KVA)

= (1 x 0.00) + (0.5 x 0.00)

0.00

KW

0.00

KVAR

0.00

KVA

SELECTION OF GENERATOR CAPACITY

2.1

2.1.1

DIESEL ENGINE GENERATOR

The selected capacity of diesel engine generator must be sufficient for each of the calculated value sh

�The maximum calculated capacity in above section for real and apparent power shall be the minimum

KW

:

KW

0.00

KVA :

KVA

0.00

2.1.1

The selected capacity of Diesel engine generator shall be:

KW G :

KW

1,000

KVAG :

PF

:

2.1.2

1,250

0.80

KVA

Lagging

Conclusion of Diesel Engine Generator Capacity

No.

Condition

Emergency Operation

Required Power

kW

Margin (%)

0.00

100.00

According to the results of this study, it is further confirmed that the capacity of generator

is sufficient for normal operation of Compressor Station

���01

02A

02B

03

04

x=

kW

116.07

359.60

196.53

501.56

501.78

CONTINUOUS

1

KVAR

84.67

220.99

128.18

373.61

274.99

KVA

143.67

422.08

234.63

625.41

572.19

TOTAL

1675.53

1082.45

1997.99

KW

144.79

384.71

206.19

562.49

510.67

NORMAL

KVAR

105.07

239.87

135.43

419.33

281.66

KVA

178.90

453.50

246.72

701.59

583.30

PRETREATMENT

PROCESS 1

PROCESS 2

PEMBANGKITAN

WATER TREATMENT

ulation Pump with motor (Fermentation and Distillation ) C

0.33

6.50

0.97

DF

RED

START

SIN START

GENERATOR DATA

Xd'

0.17

KG

1.50

KE

1.10

V DIP

0.15

PF

0.80

INT

�f the calculated value shown on Section 3.9.1.7, 3.9.2.6 , 3.9.2.8 and 3.9.2.9.

r shall be the minimum rating of the Generator

the calculated value shown on Section 2.11.

�r shall be the minimum rating of the Generator

���y=

kW

57.44

50.22

19.33

121.88

17.78

INTERMITTENT

0.50

KVAR

40.81

37.77

14.50

91.43

13.33

266.65

197.84

KVA

70.46

62.84

24.17

152.36

22.22

z=

kW

57.95

346.55

147.82

174.99

205.95

STAND-BY

0.1

KVAR

38.81

214.59

91.65

109.15

118.15

KVA

69.75

407.61

173.92

206.24

237.43

332.04

933.26

572.34

1094.95

TRAFO CALCULATION

PEAK

KW

KVAR

KVA

150.58

108.95

185.87

419.37

261.33

494.26

220.97

144.60

264.11

579.99

430.24

722.22

531.26

293.48

607.05

CAPACITY

215

544

296

842

700

CON

OPTIMAL

CHOICE Persen to Cap

600

36%

600

91%

600

49%

600

140%

600

117%

01

02A

02B

03

04

TOTAL

SAFE CHOICE

CAPACITY

CHOICE

232

600

618

600

330

600

903

600

759

600

�����x=

kW

0.00

0.00

0.00

0.00

0.00

CONTINUOUS

1

KVAR

0.00

0.00

0.00

0.00

0.00

0.00

FE CHOICE

Persen to Cap

39%

103%

55%

150%

126%

0.00

178.90

453.50

246.72

701.59

583.30

KVA

0.00

0.00

0.00

0.00

0.00

y=

kW

0.00

0.00

0.00

0.00

0.00

0.00

0.00

INTERMITTENT

0.5

KVAR

0.00

0.00

0.00

0.00

0.00

WORST CHOICE

CHOICE Persen to Cap

600

30%

600

76%

600

41%

600

117%

600

97%

0.00

KVA

0.00

0.00

0.00

0.00

0.00

z=

kW

0.00

0.00

0.00

0.00

0.00

STAND-BY

0.1

KVAR

0.00

0.00

0.00

0.00

0.00

KVA

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

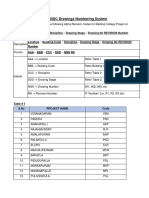

��������CLIENT :

REVISION : -

PROJECT NO

:

PROJECT NAME :

LOCATION

:

ELECTRICAL LOAD LIST

MCC FOR SUBSTATION 1

01-MCC-01

1.

2.

3.

4.

5.

6.

7.

8.

System Voltage = 400 V

System Frequency = 50 Hz

Continuous Load = Load that operated continuously during normal operation

Intermittent Load = Load that does not operate continuously but comes ON and OFF during normal operation

Standby Load = Load that does not operate during normal operation

Absorbed Load = Load that is absorbed by the driven equipment

Load Factor = Absorbed load divide by Nameplate Rating

Operating Load (kW) = Absorbed load divide by Efficiency

Operating Load (kVAR) = Operating Load (kW) x tan (arc cos j)

Power Factor = cos j

PREPARED BY :

APPROVED BY :

Reference Document :

9. Apparent Power (kVA) = SQRT (kW2 + kVAR2)

10. Maximum Load Demand = 1.0 A + 0.5 B + 0.1 C

where A = Continuous Load

B = Intermittent Load

C = Standby Load

Load

Consumed Load

Rating

Voltage Absorb.

Tag No.

Load Description

Load

Circuit

Load

Type

Type

Status

(M/F)

(Volt)

Load

(KW)

(C/I/S)

Motor

(HP)

(KW)

Others

FLA

Load

(A)

Factor

Power

Eff.

Factor

(KVA)

Continuous

Intermittent

kW

kVAR

18.29

11.33

kW

Stand-by

kVAR

Remarks

kW

kVAR

18.29

11.33

17.44

10.81

PRETREATMENT

ADDITIONAL

01-P-01A

S/S 01 Pump 01A

DOL

380

16.10

18.50

37.58

0.87

88.0%

85.0%

01-P-01 B

S/S 01 Pump 01B

DOL

380

16.10

18.50

37.58

0.87

88.0%

85.0%

01-P-02 A

S/S 01 Pump 02A

DOL

380

15.00

15.0

17.65

31.18

1.00

86.0%

85.0%

01-P-02 B

S/S 01 Pump 02B

DOL

380

15.00

15.0

17.65

31.18

1.00

86.0%

85.0%

01-LP-01

Lighting Panel Area 01 A

380

8.00

8.0

10.00

16.88

1.00

90.0%

80.0%

01-LP-02

Lighting Panel Area 01 B

380

36.00

36.0

45.00

75.97

1.00

90.0%

80.0%

01-WO-01

Welding Outlet

380

20.00

20.0

25.00

42.20

1.00

90.0%

80.0%

00-LP-01

Lighting Panel Area 00 A

380

8.00

8.0

10.00

16.88

1.00

90.0%

80.0%

8.89

6.67

NL

00-LP-02

Lighting Panel Area 00 B

380

24.00

24.0

30.00

50.64

1.00

90.0%

80.0%

26.67

20.00

NL

00-LP-03

Lighting Panel Area 00 C

380

12.00

12.0

15.00

25.32

1.00

90.0%

80.0%

13.33

10.00

NL

00-LP-04

Lighting Panel Area 00 D

380

8.00

8.0

10.00

16.88

1.00

90.0%

80.0%

8.89

6.67

NL

00-LP-05

Lighting Panel Area 00 E

380

8.00

8.0

10.00

16.88

1.00

90.0%

80.0%

8.89

6.67

NL

00-LP-06

Lighting Panel Area 00 F

380

8.00

8.0

10.00

16.88

1.00

90.0%

80.0%

8.89

6.67

NL

00-LP-07

Lighting Panel Area 00 G

380

12.00

12.0

15.00

25.32

1.00

90.0%

80.0%

13.33

10.00

NL

Total

Electrical Load Summary for Boiler

1. Demand Load

Demand Load (kW)

= 1 116.07 + 0.5 57.44

Demand Load (kVA)

= 1 143.67 + 0.5 70.46

2. Peak Load

Peak Load (kW) = 1 116.07 + 0.5 57.44 + 0.1 57.95

Peak Load (kVA) = 1 143.67 + 0.5 70.46 + 0.1 69.75

kVA

Bus No. : 01-MCC-01

= 144.79 kW

= 178.90 kVA

= 150.58 kW

= 185.87 kVA

NL

17.44

8.89

10.81

NL

6.67

30.00

NL

22.22

84.67

NL

NL

40.00

116.07

143.67

NL

57.44

70.46

40.81

57.95

69.75

16.67

38.81

400 V, 3 Phase, 50 Hz

NL

�CLIENT :

REVISION :

PROJECT NO

:

PROJECT NAME :

LOCATION

:

ELECTRICAL LOAD LIST

MCC FOR SUBSTATION 02

02-MCC-01

1.

2.

3.

4.

5.

6.

7.

8.

System Voltage = 400 V

System Frequency = 50 Hz

Continuous Load = Load that operated continuously during normal operation

Intermittent Load = Load that does not operate continuously but comes ON and OFF during normal operation

Standby Load = Load that does not operate during normal operation

Absorbed Load = Load that is absorbed by the driven equipment

Load Factor = Absorbed load divide by Nameplate Rating

Operating Load (kW) = Absorbed load divide by Efficiency

Operating Load (kVAR) = Operating Load (kW) x tan (arc cos j)

Power Factor = cos j

PREPARED BY :

APPROVED BY :

Reference Document :

9. Apparent Power (kVA) = SQRT (kW2 + kVAR2)

10. Maximum Load Demand = 1.0 A + 0.5 B + 0.1 C

where A = Continuous Load

B = Intermittent Load

C = Standby Load

Load

Consumed Load

Rating

Tag No.

Load Description

Voltage

(Volt)

Absorb.

Load

(KW)

Load

Type

(M/F)

Circuit

Type

Load

Status

(C/I/S)

C

S

C

S

C

S

C

S

C

S

C

S

C

S

C

S

C

C

C

C

C

C

380

380

380

380

380

380

380

380

380

380

380

380

380

380

380

380

380

380

380

380

380

380

58.40

58.40

69.20

69.20

26.10

26.10

2.40

2.40

6.00

6.00

0.20

0.20

0.20

0.20

3.60

3.60

2.27

2.27

11.20

11.20

1.50

47.85

FLA

(A)

Load

Factor

Eff.

Power

Factor

75.00

75.00

90.00

90.00

30.00

30.00

3.00

3.00

7.50

7.50

0.25

0.25

0.25

0.25

5.50

5.50

3.70

3.70

14.00

14.00

1.50

55.00

143.09

143.09

170.60

170.60

59.58

59.58

7.35

7.35

16.35

16.35

0.61

0.61

0.61

0.61

12.90

12.90

8.78

8.78

29.44

29.44

3.67

105.39

0.87

0.87

0.91

0.91

0.87

0.87

0.80

0.80

0.80

0.80

0.80

0.80

0.80

0.80

0.80

0.80

0.80

0.80

0.80

0.80

0.80

0.87

92.6%

92.6%

93.2%

93.2%

90.0%

90.0%

78.5%

78.5%

82.0%

82.0%

78.5%

78.5%

78.5%

78.5%

81.0%

81.0%

80.0%

80.0%

85.0%

85.0%

78.5%

92.2%

86.0%

86.0%

86.0%

86.0%

85.0%

85.0%

79.0%

79.0%

85.0%

85.0%

79.0%

79.0%

79.0%

79.0%

80.0%

80.0%

80.0%

80.0%

85.0%

85.0%

79.0%

86.0%

Motor

(HP)

(KW)

Others

(KVA)

Continuous

kW

kVAR

63.07

37.42

74.25

44.06

29.00

17.97

Intermittent

kW

Stand-by

kVAR

P-2101 A

P-2101 B

P-2102 A

P-2102 B

P-2103 A

P-2103 B

P-2104 A

P-2104 B

P-2105A

P-2105B

P-2106 A

P-2106 B

P-2107 A

P-2107 B

P-2108 A

P-2108 B

P-2109 A

P-2109 B

A-2101

A-2102

A-2103

P-2110 A

PROCESS A

S/S 02A Pump 01A

S/S 02A Pump 01B

S/S 02A Pump 02A

S/S 02A Pump 02B

S/S 02A Pump 03A

S/S 02A Pump 03B

S/S 02A Pump 04A

S/S 02A Pump 04B

S/S 02A Pump 05A

S/S 02A Pump 05B

S/S 02A Pump 06A

S/S 02A Pump 06B

S/S 02A Pump 07A

S/S 02A Pump 07B

S/S 02A Pump 08A

S/S 02A Pump 08B

S/S 02A Pump 09A

S/S 02A Pump 09B

S/S 02A Agitator motor 01

S/S 02A Agitator motor 02

S/S 02A Agitator motor 03

S/S 02A Pump 10A

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

DOL

DOL

DS

DS

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

P-2110 B

S/S 02A Pump 10B

DOL

380

47.85

55.00

105.39

0.87

92.2%

86.0%

P-2111 A

S/S 02A Pump 11A

DOL

380

47.85

55.00

105.39

0.87

92.2%

86.0%

P-2111 B

S/S 02A Pump 11B

DOL

380

47.85

55.00

105.39

0.87

92.2%

86.0%

P-2112 A

S/S 02A Pump 12A

DOL

380

20.20

30.00

59.58

0.87

90.0%

85.0%

P-2112 B

P-2113 A

P-2113 B

P-2113 C

S/S 02A Pump 12B

S/S 02A Pump 13A

S/S 02A Pump 13B

S/S 02A Pump 13C

M

M

M

M

DOL

DOL

DOL

DOL

S

I

I

I

380

380

380

380

20.20

1.00

1.00

1.00

30.00

1.00

1.00

1.00

59.58

2.45

2.45

2.45

0.87

0.80

0.80

0.80

90.0%

78.5%

78.5%

78.5%

85.0%

79.0%

79.0%

79.0%

1.27

1.27

1.27

0.99

0.99

0.99

3.06

2.37

7.32

4.53

0.25

0.25

kVAR

63.07

37.42

74.25

44.06

29.00

17.97

3.06

2.37

7.32

4.53

0.25

0.20

0.25

0.20

4.44

3.33

51.90

30.79

51.90

30.79

22.44

13.91

0.20

0.20

4.44

3.33

2.84

2.84

13.18

13.18

1.91

51.90

2.13

2.13

8.17

8.17

1.48

30.79

51.90

30.79

22.44

kW

Remarks

NL

NL

NL

NL

NL

NL

NL

NL

NL

NL

NL

NL

EL

EL

EL

EL

EL

EL

EL

EL

EL

NL

NL

NL

13.91

NL

NL

NL

NL

NL

NL

OTHERS

02-LP-01

Lighting Panel Area 02 A

380

20.88

24.00

30.00

50.64

0.87

90.0%

80.0%

23.20

17.40

EL

02-LP-02

Lighting Panel Area 02 B

380

20.88

24.00

30.00

50.64

0.87

90.0%

80.0%

23.20

17.40

NL

02-WO-01

Welding Outlet

380

17.40

20.00

25.00

42.20

0.87

90.0%

80.0%

19.33

14.50

NL

02-WO-02

Welding Outlet

380

17.40

20.00

25.00

42.20

0.87

90.0%

80.0%

19.33

14.50

NL

02-UPS-01

UPS A

380

16.00

32.00

40.00

67.53

0.50

90.0%

80.0%

Total

kVA

Electrical Load Summary for Boiler

1. Demand Load

Demand Load (kW)

= 1 359.60 + 0.5 50.22

Bus No. : 02-MCC-01

= 384.71 kW

17.78

13.33

359.60

220.99

422.08

EL

50.22

62.84

37.77

346.55

214.59

407.61

400 V, 3 Phase, 50 Hz

�CLIENT :

REVISION :

PROJECT NO

:

PROJECT NAME :

LOCATION

:

ELECTRICAL LOAD LIST

MCC FOR SUBSTATION 02

02-MCC-01

1.

2.

3.

4.

5.

6.

7.

8.

System Voltage = 400 V

System Frequency = 50 Hz

Continuous Load = Load that operated continuously during normal operation

Intermittent Load = Load that does not operate continuously but comes ON and OFF during normal operation

Standby Load = Load that does not operate during normal operation

Absorbed Load = Load that is absorbed by the driven equipment

Load Factor = Absorbed load divide by Nameplate Rating

Operating Load (kW) = Absorbed load divide by Efficiency

Operating Load (kVAR) = Operating Load (kW) x tan (arc cos j)

Power Factor = cos j

PREPARED BY :

APPROVED BY :

Reference Document :

9. Apparent Power (kVA) = SQRT (kW2 + kVAR2)

10. Maximum Load Demand = 1.0 A + 0.5 B + 0.1 C

where A = Continuous Load

B = Intermittent Load

C = Standby Load

Load

Consumed Load

Rating

Tag No.

Load Description

Demand Load (kVA)

= 1 422.08 + 0.5 62.84

2. Peak Load

Peak Load (kW) = 1 359.60 + 0.5 50.22 + 0.1 346.55

Peak Load (kVA) = 1 422.08 + 0.5 62.84 + 0.1 407.61

Load

Type

(M/F)

Circuit

Type

= 453.50 kVA

= 419.37 kW

= 494.26 kVA

Load

Status

(C/I/S)

Voltage

(Volt)

Absorb.

Load

(KW)

Motor

(HP)

(KW)

Others

(KVA)

FLA

(A)

Load

Factor

Eff.

Power

Factor

Continuous

kW

kVAR

Intermittent

kW

kVAR

Stand-by

kW

kVAR

Remarks

�CLIENT :

REVISION :

PROJECT NO

:

PROJECT NAME :

LOCATION

:

ELECTRICAL LOAD LIST

MCC FOR SUBSTATION 02

02-MCC-02

1.

2.

3.

4.

5.

6.

7.

8.

System Voltage = 400 V

System Frequency = 50 Hz

Continuous Load = Load that operated continuously during normal operation

Intermittent Load = Load that does not operate continuously but comes ON and OFF during normal operation

Standby Load = Load that does not operate during normal operation

Absorbed Load = Load that is absorbed by the driven equipment

Load Factor = Absorbed load divide by Nameplate Rating

Operating Load (kW) = Absorbed load divide by Efficiency

Operating Load (kVAR) = Operating Load (kW) x tan (arc cos j)

Power Factor = cos j

PREPARED BY :

APPROVED BY :

Reference Document :

EQUIPMENT LIST

9. Apparent Power (kVA) = SQRT (kW2 + kVAR2)

10. Maximum Load Demand = 1.0 A + 0.5 B + 0.1 C

where A = Continuous Load

B = Intermittent Load

C = Standby Load

Load

Consumed Load

Rating

Tag No.

Load Description

Load

Type

(M/F)

Voltage Absorb.

Circuit Load

(Volt)

Load

Type Status

(KW)

(C/I/S)

Motor

(HP)

(KW)

Others

FLA

(A)

Load

Factor

Power

Factor

Eff.

(KVA)

P-2201 A

PROCESS B

S/S 02B Pump 01A

DOL

380

26.10

30.00

59.58

0.87

90.0%

85.0%

P-2201 B

S/S 02B Pump 01B

DOL

380

26.10

30.00

59.58

0.87

90.0%

85.0%

P-2202 A

S/S 02B Pump 02A

DOL

380

19.14

22.00

44.43

0.87

88.5%

85.0%

P-2202 B

S/S 02B Pump 02B

DOL

380

19.14

22.00

44.43

0.87

88.5%

85.0%

P-2203 A

S/S 02B Pump 03A

DOL

380

1.20

1.50

3.67

0.80

78.5%

79.0%

P-2203 B

S/S 02B Pump 03B

DOL

380

1.20

1.50

3.67

0.80

78.5%

79.0%

P-2204 A

S/S 02B Pump 04A

DOL

380

1.20

1.50

3.67

0.80

78.5%

79.0%

P-2204 B

S/S 02B Pump 04B

DOL

380

1.20

1.50

3.67

0.80

78.5%

79.0%

P-2205 A

S/S 02B Pump 05A

DOL

380

65.25

75.00

143.09

0.87

92.6%

86.0%

P-2205 B

S/S 02B Pump 05B

DOL

380

65.25

75.00

143.09

0.87

92.6%

86.0%

P-2206 A

S/S 02B Pump 06A

DOL

380

12.00

15.00

31.18

0.80

86.0%

85.0%

P-2206 B

S/S 02B Pump 06B

DOL

380

12.00

15.00

31.18

0.80

86.0%

85.0%

P-2207 A

S/S 02B Pump 07A

DOL

380

1.20

1.50

3.67

0.80

78.5%

79.0%

P-2207 B

S/S 02B Pump 07B

DOL

380

1.20

1.50

3.67

0.80

78.5%

79.0%

P-2208 A

S/S 02B Pump 08A

DOL

380

2.96

3.70

8.78

0.80

80.0%

80.0%

P-2208 B

S/S 02B Pump 08B

DOL

380

2.96

3.70

8.78

0.80

80.0%

80.0%

P-2209 A

S/S 02B Pump 09A

DOL

380

1.76

2.20

5.39

0.80

78.5%

79.0%

P-2209 B

S/S 02B Pump 09B

DOL

380

1.76

2.20

5.39

0.80

78.5%

79.0%

P-2210 A

S/S 02B Pump 10A

DOL

380

1.76

2.20

5.39

0.80

78.5%

79.0%

P-2210 B

S/S 02B Pump 10B

DOL

380

1.76

2.20

5.39

0.80

78.5%

79.0%

Continuous

kW

kVAR

29.00

17.97

21.63

1.53

1.53

70.46

13.95

1.53

3.70

2.24

2.24

Intermittent

kW

Stand-by

kVAR

Remarks

kW

kVAR

29.00

17.97

21.63

13.40

1.53

1.19

1.53

1.19

70.46

41.81

13.95

8.65

1.53

1.19

3.70

2.78

2.24

1.74

2.24

1.74

NL

13.40

NL

NL

1.19

NL

NL

1.19

NL

NL

41.81

NL

NL

8.65

NL

NL

1.19

NL

EL

2.78

EL

EL

1.74

EL

EL

1.74

EL

EL

EL

OTHERS

Lighting Panel Area 02 C

380

27.84

32.00

40.00

67.53

0.87

90.0%

80.0%

30.93

23.20

02-UPS-02

UPS B

380

16.00

32.00

40.00

67.53

0.50

90.0%

80.0%

17.78

13.33

02-UPS-03

UPS C

380

0.00

32.00

40.00

67.53

0.00

90.0%

80.0%

Space Heater

380

17.40

20.00

25.00

42.20

0.87

90.0%

80.0%

02-LP-03

02-SH-1

Total

kVA

Electrical Load Summary for Boiler

1. Demand Load

Demand Load (kW)

= 1 196.53 + 0.5 19.33

Demand Load (kVA)

= 1 234.63 + 0.5 24.17

2. Peak Load

Peak Load (kW) = 1 196.53 + 0.5 19.33 + 0.1 147.82

Peak Load (kVA) = 1 234.63 + 0.5 24.17 + 0.1 173.92

Bus No. : 02-MCC-02

= 206.19 kW

= 246.72 kVA

= 220.97 kW

= 264.11 kVA

EL

EL

0.00

19.33

196.53

128.18

234.63

19.33

24.17

0.00

14.50

14.50

EL

EL

147.82

173.92

91.65

400 V, 3 Phase, 50 Hz

�CLIENT :

REVISION :

PROJECT NO

ELECTRICAL LOAD LIST

PREPARED BY :

PROJECT NAME :

MCC FOR SUBSTATION 03

APPROVED BY :

LOCATION

03-MCC-01

1. Continuous Load = Load that operated continuously during normal operation

2. Intermittent Load = Load that does not operate continuously but comes ON and OFF during normal operation

3. Standby Load = Load that does not operate during normal operation

4. Absorbed Load = Load that is absorbed by the driven equipment

System Voltage = 400 V

Reference Document :

5. Load Factor = Absorbed load divide by Nameplate Rating

System Frequency = 50 Hz

EQUIPMENT LIST

6. Operating Load (kW) = Absorbed load divide by Efficiency

7. Operating Load (kVAR) = Operating Load (kW) x tan (arc cos j)

8. Power Factor = cos j

9. Apparent Power (kVA) = SQRT (kW2 + kVAR2)

10. Maximum Load Demand = 1.0 A + 0.5 B + 0.1 C

where A = Continuous Load

B = Intermittent Load

C = Standby Load

Load

Consumed Load

Rating

Voltage Absorb.

Tag No.

Load Description

Load

Circuit

Load

Type

Type

Status

(M/F)

(C/I/S)

(Volt)

Load

(KW)

Motor

(HP)

(KW)

Others

FLA

Load

(A)

Factor

Power

Eff.

Factor

(KVA)

Continuous

kW

kVAR

380

290

Intermittent

Stand-by

kW

kVAR

33.33

25.00

kW

Remarks

kVAR

03-MCC-A

Local Panel for Boiler

380

03-MCC-B

Local Panel for STG

380

30.00

30.0

63.31

1.00

90.0%

80.0%

P-301 A

S/S 03 Pump 01A

DS

380

12.00

15.00

31.18

0.80

86.0%

85.0%

13.95

8.65

NL

P-301 B

S/S 03 Pump 01B

DS

380

12.00

15.00

31.18

0.80

86.0%

85.0%

13.95

8.65

NL

P-302 A

S/S 03 Pump 02A

DOL

380

0.60

0.75

1.84

0.80

78.5%

79.0%

P-302 B

S/S 03 Pump 02B

DOL

380

0.60

0.75

1.84

0.80

78.5%

79.0%

0.76

0.59

Local Panel for Coal Handling System

DOL

380

18.00

18.0

37.98

1.00

90.0%

80.0%

03-MCC-C

NL

0.76

20.00

NL

0.59

NL

15.00

NL

EL

ADDITIONAL

P-303 A

S/S 03 Pump 03A

DS

380

81.81

90.00

170.60

0.91

93.2%

86.0%

87.78

52.08

NL

P-303 B

S/S 03 Pump 03B

DOL

380

6.00

7.50

16.35

0.80

82.0%

85.0%

7.32

4.53

NL

S/S 03 Pump 04

DOL

380

26.10

30.00

59.58

0.87

90.0%

85.0%

29.00

17.97

P-305 A

S/S 03 Pump 05A

DOL

380

26.10

30.00

59.58

0.87

90.0%

85.0%

29.00

17.97

P-305 B

S/S 03 Pump 05B

DOL

380

26.10

30.00

59.58

0.87

90.0%

85.0%

P-304

NL

NL

29.00

17.97

NL

Others

17.78

13.33

03-BC-01

Baterry charger

380

16.00

16.00

20.00

33.76

1.00

90.0%

80.0%

03-BC-02

Battery for STG

380

55.00

55.00

70.00

116.06

1.00

90.0%

80.0%

03-BC-03

Battery RCP STG

220

1.60

1.60

2.00

5.83

1.00

90.0%

80.0%

1.78

1.33

EL

03-BC-04

Battery RCP DEG

220

1.60

1.60

2.00

5.83

1.00

90.0%

80.0%

1.78

1.33

EL

03-CP-01

Cathodic Protection

380

4.00

4.00

5.00

8.44

1.00

90.0%

80.0%

4.44

3.33

EL

03-LP-01

Lighting Panel Area 03 A

380

16.00

16.0

20.00

33.76

1.00

90.0%

80.0%

17.78

13.33

03-LP-02

03-WP-01

Lighting Panel Area 03B

380

24.00

24.0

30.00

50.64

1.00

90.0%

80.0%

Welding Outlet

380

20.00

20.0

25.00

42.20

1.00

90.0%

80.0%

Total

Electrical Load Summary for Boiler

1. Demand Load

Demand Load (kW) = 1 501.56 + 0.5 121.88

= 562.49 kW

Demand Load (kVA) = 1 625.41 + 0.5 152.36

= 701.59 kVA

2. Peak Load

Peak Load (kW)

= 1 501.56 + 0.5 121.88 + 0.1 174.99= 579.99 kW

Peak Load (kVA)

= 1 625.41 + 0.5 152.36 + 0.1 206.24= 722.22 kVA

kVA

Bus No. :03-MCC-01

EL

61.11

45.83

EL

EL

26.67

20.00

NL

22.22

501.56

373.61

625.41

121.88

152.36

91.43

16.67

174.99

109.15

206.24

400 V, 3 Phase, 50 Hz

NL

�CLIENT :

REVISION :

PROJECT NO

ELECTRICAL LOAD LIST

PREPARED BY :

PROJECT NAME :

MCC FOR SUBSTATION 04

APPROVED BY :

LOCATION

04-MCC-01

1. Continuous Load = Load that operated continuously during normal operation

2. Intermittent Load = Load that does not operate continuously but comes ON and OFF during normal operation

3. Standby Load = Load that does not operate during normal operation

4. Absorbed Load = Load that is absorbed by the driven equipment

System Voltage = 400 V

Reference Document :

5. Load Factor = Absorbed load divide by Nameplate Rating

System Frequency = 50 Hz

EQUIPMENT LIST

6. Operating Load (kW) = Absorbed load divide by Efficiency

7. Operating Load (kVAR) = Operating Load (kW) x tan (arc cos j)

8. Power Factor = cos j

9. Apparent Power (kVA) = SQRT (kW2 + kVAR2)

10. Maximum Load Demand = 1.0 A + 0.5 B + 0.1 C

where A = Continuous Load

B = Intermittent Load

C = Standby Load

Load

Consumed Load

Rating

Voltage Absorb.

Tag No.

Load Description

Load

Circuit

Load

Type

Type

Status

(Volt)

Load

(KW)

Motor

(HP)

(KW)

Others

FLA

Load

(A)

Factor

Power

Eff.

Factor

(KVA)

Continuous

(M/F)

(C/I/S)

Local Panel Water Treatment

380

P-401 A

P-401 B

P-411 A

S/S 04 Pump 01A

S/S 04 Pump 01B

Cooling Water Pump 11 A

M

M

M

DOL

DOL

DS

C

S

C

380

380

380

26.10

26.10

145.44

30.00

30.00

160.00

59.58

59.58

293.88

0.87

0.87

0.91

90.0%

90.0%

94.0%

85.0%

85.0%

88.0%

154.72

83.51

P-411 B

Cooling Water Pump 11 B

DS

380

145.44

160.00

293.88

0.91

94.0%

88.0%

154.72

83.51

P-411 C

Cooling Water Pump 11 C

DS

380

145.44

160.00

293.88

0.91

94.0%

88.0%

04-MCC-A

150

kW

kVAR

150

80

29.00

17.97

Intermittent

kW

Stand-by

kVAR

kW

Remarks

kVAR

NL

29.00

17.97

154.72

83.51

NL

NL

EL

NL

NL

Others

04-LP-01

Lighting Panel Area 05 A

380

8.00

8.0

10.00

16.88

1.00

90.0%

80.0%

04-LP-02

Lighting Panel Area 05 B

380

16.00

16.0

20.00

33.76

1.00

90.0%

80.0%

04-CP-01

Cathodic Protection

380

4.00

4.00

5.00

8.44

1.00

90.0%

80.0%

04-WO-01

Welding Outlet

380

20.00

20.0

25.00

42.20

1.00

90.0%

80.0%

Total

Electrical Load Summary for Boiler

1. Demand Load

Demand Load (kW)

= 1 501.78 + 0.5 17.78

Demand Load (kVA)

= 1 572.19 + 0.5 22.22

2. Peak Load

Peak Load (kW) = 1 501.78 + 0.5 17.78 + 0.1 205.95

Peak Load (kVA) = 1 572.19 + 0.5 22.22 + 0.1 237.43

kVA

Bus No. : 04-MCC-01

= 510.67 kW

= 583.30 kVA

= 531.26 kW

= 607.05 kVA

8.89

6.67

EL

17.78

4.44

13.33

NL

3.33

EL

22.22

501.78

274.99

572.19

17.78

22.22

13.33

16.67

205.95

118.15

237.43

400 V, 3 Phase, 50 Hz

NL

�URUTAN NGAJAR

1 drawing single line diagram

2 Rename komponen

3 Masukan rating

4 Load flow

5 masuk ke revision , pengenalan SF, Loading Factor dan PF dan Efisiensi

�DATA MOTOR

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

18

pump manufacturer data

EFFICIENCY @POWER

Rating FACTOR @ Rating

RATING

LOAD FACTOR (%)SERVICE FACTOR

100%

100%

0.25

78.5%

79.0%

80.0%

1

0.75

78.5%

79.0%

80.0%

1

1

78.5%

79.0%

80.0%

1

1.5

78.5%

79.0%

80.0%

1

2.2

78.5%

79.0%

80.0%

1

3

78.5%

79.0%

80.0%

1

3.7

80.0%

80.0%

80.0%

1

5.5

81.0%

80.0%

80.0%

1

7.5

82.0%

85.0%

80.0%

1

14

85.0%

85.0%

80.0%

1

15

86.0%

85.0%

80.0%

1

18

88.0%

85.0%

80.0%

1

18.5

88.0%

85.0%

87.0%

1

22

88.5%

85.0%

87.0%

1

30

90.0%

85.0%

87.0%

1

55

92.2%

86.0%

90.9%

1

75

92.6%

86.0%

90.9%

1

90

93.2%

86.0%

90.9%

1

160

94.0%

88.0%

90.9%

1