0% found this document useful (0 votes)

66 views3 pagesDue: 10/16/13 Name: ID #:: Isentropic Efficiency of The Compressor Is 85 Percent and That For The Turbine Is 90 Percent

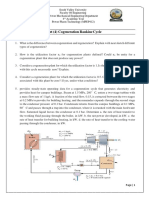

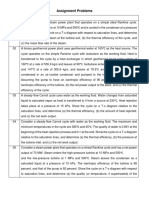

This document contains 4 problems related to cogeneration plants. Problem 1 involves determining the net power produced and utilization factor for a plant where steam is extracted from the turbine at 600 kPa and condensed. Problem 2 involves determining the power produced and process heat supplied for two different operating modes. Problem 3 involves determining the net power produced and steam flow rate for a plant with regeneration where steam is extracted from the turbine. Problem 4 involves determining the air flow rate required to produce 100 MW of power for a combined gas-steam plant.

Uploaded by

Omar KandilCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

66 views3 pagesDue: 10/16/13 Name: ID #:: Isentropic Efficiency of The Compressor Is 85 Percent and That For The Turbine Is 90 Percent

This document contains 4 problems related to cogeneration plants. Problem 1 involves determining the net power produced and utilization factor for a plant where steam is extracted from the turbine at 600 kPa and condensed. Problem 2 involves determining the power produced and process heat supplied for two different operating modes. Problem 3 involves determining the net power produced and steam flow rate for a plant with regeneration where steam is extracted from the turbine. Problem 4 involves determining the air flow rate required to produce 100 MW of power for a combined gas-steam plant.

Uploaded by

Omar KandilCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

/ 3