SCHOOL OF CHEMICAL & BIOMEDICAL ENGINEERING

CHEMICAL & BIOMOLECULAR ENGINEERING

CHEMICAL/ BIOMOLECULAR ENGINEERING LABORATORY 2

Year 1: Material/ Energy Balance for a

Combustion

Process at Steady State

Name: Muhammad Ilyas Hassan

Matriculation Number: U1322800G

Group: 6

Date of Experiment: 24

th

Feb 2014

1. Aim

The objective of the experiment is to derive the material and

energy balance formula for a steady-state combustion process by

calculating the air excess ratio, stoichiometry, higher heating

value, lower heating value, etc and thus, understand the concept

of a steady state combustion process and the technique of Gas

Chromatography.

2. Abstract

The traditional combustion process is heavily used today for to

drive many purposes and processes mainly due to its energy

output. In this combustion process, a substance with high bond

energy typically hydrocarbons, are used to be burnt excess air,

due to its oxygen content, to produce a great deal of energy.

Typical end products for combustion is carbon dioxide and water,

sometimes carbon monoxide, depending on weather the supply of

oxygen is limited or not. There are many methods to determine

the air content to monitor the combustion process and one way is

the use of Gas Chromatography. In this study, we explore the basic

principles unlying the combustion process by combusting

propane, C3H8 with excess air and monitoring its mass and energy

balance using selected methods of calculation from experimental

values and not to mention, Gas Chromatography to give us a

clearer idea of combustion as a whole.

3. Principles

3.1 Stoichiometry Equation and Conditions

Just like any other chemical process/experiment, we have to

understand the theoretical or stoichiometrical equation of the

combustion process, which not only shows the chemical

compositions of the reactants and products, but also the

theoretical or ideal mole ratios.

The conditions at which the reactions take place also matter, as it

affects the compositions and enthalpies of the chemical

substances. In this experiment, the combustion takes place at

atmospheric pressure of 1 atm and room temperature of 24.4

o

C.

Under the atmospheric pressure, a fuel (propane gas) reacts with

O2 (Air, O2: N2 = 1 :3.76 ) and this process is exothermic and the

stoichiometric combustion formula is:

C

3

H

8

+5(O

2

+3.76N

2

) 3CO

2

+4H

2

O+18.8N

2

+ H where H is enthalphy

of combustion

As the Air/fuel ratio changes, the enthalpy of combustion and the

composition of the product (exhaust gases) will change

accordingly. However, the principles of energy and materials

balance are always valid and can be used to solve the unknowns.

3.2 Mass Balance and Terminologies

Mass balance is the calculation of the different amount of

reactants and/or products based on given values and the

stoichiometric equation above. It gives us specific figures on the

amounts of input and output to the system, which in this case is

the Fireboy burner, the combustion chamber where the

process takes place.

Theoretical & Excess Air: Theoretical air is the quantity of air

that contains theoretical oxygen (5 moles in the above example)

Percent excess air:

(moles air)

fed

(moles air)

theo

100%

(moles air)

theo

Dry and Wet basis: composition on a wet basis denotes the

component mole fractions of a gas that contains water;

composition on a dry basis signifies the component mole fraction

of the same gas without water.

3.3 Energy Balance

Similar to mass, the energy balance helps us find the energy

output of the combustion process. Energy balance is based on 1

st

Law of Thermodynamics, law of the conservation of energy.

First laws for open system at steady state: Our system is the

open system at steady state, the first

laws can be written as:

Fig 1: First laws for open system at steady state

Where,

Fig 2: Heat component of the equation on the open system at steady state

Standard heat (enthalpy) of combustion, H

c

0

: the heat of

reaction of the substance with oxygen to yield specific products

(e.g., CO

2

, H

2

O), with both reactants and products are at the

reference

temperature and pressure (25C, 1 atm).

Standard heat (enthalpy) of formation, H

0

f

: enthalpy change

associated with the formation of 1 mole compound from naturally

occurring elements under reference state (25C, 1 atm ).

The heat of combustion is related to heat of formation:

H

0

=

H

0

H

0

Enthalpy changes for processes involving chemical reaction:

Two methods exists for the calculation of the overall enthalpies

changes, they are: (1) heat of reaction method (molecular species

at 25C, 1atm), and (2) heat of formation method (naturally

occurring elemental species at 25C, 1atm). In this experiment,

the former method is used.

3.4 Gas Chromatography

Gas Chromatography (GC) is a technique used to separate

substances that are volatile. It makes use of an inert carrier gas to

separate the compounds due to their differences in partitioning

behavior between the mobile gas phase and the stationary phase

in the column. Simply said, this technique helps in the analysis of

the exhaust gas for the combustion process. More about GC in the

Appendix A.

4. Equipment and Materials

The experiment is fairly a straight-forward one with 3 main

parts; combustion, sampling and analysis.

Combustion chamber

Fireboy burners equipped with quartz tube are used as the

combustion device (chambers), propane gas as the fuel.

A MKS Mass gas flow controller is used to regulate the volumetric

flow rate of the fuel gas. Shimadzu GC 14B is used to analyze the

composition of the exhaust gases (Appendix I).

Air sampling

A micro-syringe is used as the sampling device.

Analysis

Gas Chromatogram

Other equipments include common lab apparatus including the

traditional thermometer.

5. Procedure

The experiment is fairly a straight-forward one with 3 main

parts; combustion, sampling and analysis. A brief outline of the

procedure is listed below.

1. The GC was started first to ensure that the base-line was

stable before using later in the experiment.

2. Gas fuel supply was turned on, in which at the same time

the mass flow controller (MFC) was switched on and checked

zero.

3. Propane flow rate was set, and the process was ignited.

4. Waiting time of 3 minutes to ensure that the process has

gone to steady

state.

5. Sample of the exhaust gas was taken using the micro-

syringe and the

temperature was recorded.

6. Sample gas was injected into the analytical port of the GC

before starting the analysis.

7. Computation and calculation of results

6. Results and Calculations

6.1 GC Analysis

The Gas Chromatography (GC) technique was used to analyse

and determine the content composition of the air mixture sample

drawn from the outlet of the Fireboy burner, that was taken

using the micro-syringe.

Table 1 below is taken straight from the GC.

GC Results Mole fraction (dry basis)

CO2 0.1030

N2 0.8290

02 0.0680

Total (dry basis) 1.0000

H20 0.1373

Total (wet basis) 1.1373

Table 1: GC analysis results (dry basis)

Table 2 is derived from table one, taking into account the water

vapour content of the gas.

Wet basis Mole fraction (wet basis)

CO2 0.09056272

N2 0.728898007

O2 0.05978898

H20 0.120750293

Total (wet basis) 1.000

Table 2: GC Analysis Results (wet basis)

6.2 Results

Using the above data from the GC, the mass and energy balances

and the input molar flow rate of the propane gas, the respective

values for the different components of input and output were able

to be determined using calculations.

Below are the tabulated results from the calculations:

D

a

t

a

c

a

l

c

u

Table 3: Tabulation of all calculations and results

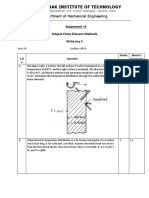

6.3 Calculations and Derivations

Below are the workings showing the derivation of the values

tabulated above. These values are calculated in sequential order

and makes use of relevant assumptions and mass and energy

balances. Below is a simplified diagram of the system.

Inlet Outlet GC analysis

Y

i

n

i

^

H

i

y

i

n

i

^

H

i

1

% mol/s kJ/mol % mol/s kJ/mol

mol frac

N

2

76.50

6.665 x

10

-3

0 72.90

6.665 x

10

-3

11.080 0.728898007

O

2

20.33

1.772 x

10

-3

0 5.98

5.467 x

10

-4

12.061 0.05978898

C

3

H

8

3.17

2.76042

x 10

-4

0 nil nil nil 0

H

2

O

nil nil nil 12.08

1.104 x

10

-3

13.132 0.120750293

CO

2

Nil nil nil 9.06

8.281 x

10

-4

16.967 0.09056272

CO

nil nil nil nil nil nil 0

Fig 3: Simple diagram of the open system

6.3.1 Flow Rate of Propane Gas (Inlet)

Visual Flow Rate of C3H8 = 371 cm

3

/ min

1 mol of (any) gas has a net volume of 24dm

3

= 24000cm

3

at R.T.P

Flow Rate of C3H8 = 371 cm

3

/ min x 1mol/ 24000cm

3

x 1min/ 60s

= 2.76042 x 10

-4

mol/s

6.3.2 Flow Rate of Carbon Dioxide (Outlet)

Stoichiometric Equation:

C3H8 + 5(O2 + 3.76N2) 3CO2 + 4H2O + 18.8N2 + H

For this equation to be valid, it was assumed that complete

combustion occurred and was justified with the absence of a

Carbon Monoxide product of incomplete combustion.

Flow Rate of CO2 = 3 x 2.76042 x 10

-4

mol/s = 8.281 x 10

-4

mol/s

Q

T

in

=

25C

T

out

=

401C

n

prop

n

oxy

n

n

prop

n

oxy

n

nitro

n

CO

2

n

CO

n

water

6.3.3 Flow Rate of Water (Outlet)

Stoichiometric Equation:

C3H8 + 5(O2 + 3.76N2) 3CO2 + 4H2O + 18.8N2 + H

For this equation to be valid, it was assumed that complete

combustion occurred and was justified with the absence of a

Carbon Monoxide product of incomplete combustion.

Flow Rate of H2O = 4 x 2.76042 x 10

-4

mol/s = 1.104 x 10

-3

mol/s

6.3.4 Flow Rate of Nitrogen (Outlet)

Stoichiometric Equation:

C3H8 + 5(O2 + 3.76N2) 3CO2 + 4H2O + 18.8N2 + H

The flow rate of Nitrogen and Oxygen cannot be obtained using

the stoichiometric ratio with the basis of Propane gas (i.e 18.8 x

2.5347 x 10

-4

mol/s). This is based on the chromatogram

obtained, there are no peaks indicative of Carbon Monoxide. This

implies that complete combustion has occurred yielding the

Carbon Dioxide and Water. However, we can assume that since

Propane gas has undergone complete combustion, the limiting

reactant is thus Propane. This can inevitably mean that the air

was supplied in excess to ensure that complete combustion

occurs. Thus the stoichiometric values and coefficient will not

give a fair and reliable representation of answer due to the fuel

air ratio. It is only recommended that we check with the

chromatogram and use the comparison method for the answers.

Based on GC, the mol frac of CO2 = 0.09056272

0.09056272 = 8.281 x 10

-4

mol/s

Based on GC, the mol fraction of N2 = 0.728898007

Flow Rate of N2 = [(8.281 x 10

-4

mol/s)/ 0.09056272] x

0.728898007

Flow Rate of N2 = 6.665 x 10

-3

mol/s

6.3.5 Flow Rate of Oxygen (Outlet)

Stoichiometric Equation:

C3H8 + 5(O2 + 3.76N2) 3CO2 + 4H2O + 18.8N2 + H

Based on GC, the mol frac of CO2 = 0.09056272

0.09056272 = 8.281 x 10

-4

mol/s

Based on GC, the mol fraction of O2 = 0.05978898

Flow Rate of O2 = [(8.281 x 10

-4

mol/s)/ 0.09056272] x

0.05978898

Flow Rate of O2 = 5.467 x 10

-4

mol/s

6.3.6 Flow Rate of Nitrogen (Inlet)

Stoichiometric Equation:

C3H8 + 5(O2 + 3.76N2) 3CO2 + 4H2O + 18.8N2 + H

Flow Rate of N2 (Inlet) = Flow Rate of N2 (Outlet) = 6.665 x 10

-3

mol/s

This is due to the nature of inertness of Nitrogen Gas.

The inlet flow rate of Nitrogen is the same to that of the outlet

flow rate of Nitrogen due to its inertness and its presence in the

chromatogram despite the fact that complete combustion will not

yield any Nitrogen products. The presence of Nitrogen is due to

its role as a constituent in air and is part of the air fuel ratio.

This is because, for every 1 mole of Oxygen, there is 3.76 moles of

Nitrogen. Thus the chromatogram which displays the peak for

Nitrogen simply implies that this Nitrogen gas constituent is non

reactive as it does not contribute to the combustion but it is

present due to its function as a component of air. Hence, the

number of moles of inlet Nitrogen gas is the same as the outlet.

6.3.7 Flow Rate of Oxygen (Inlet)

Stoichiometric Equation:

C3H8 + 5(O2 + 3.76N2) 3CO2 + 4H2O + 18.8N2 + H

For every 1 mole of Oxygen, there is 3.76 moles of Nitrogen

Flow Rate of N2 (Inlet) = 6.665 x 10

-3

mol/s

Flow Rate of O2 (Inlet) = (6.665 x 10

-3

mol/s)/ 3.76 = 1.772 x 10

-3

mol/s

6.3.8 Inlet Molar Flow Rate and Mole Fraction

Inlet Molar Flow Rate = n total (C3H8 + O2 + N2)

Inlet Molar Flow Rate = 6.665 x 10

-3

mol/s + 1.772 x 10

-3

mol/s +

2.76042 x 10

-4

mol/s

Inlet Molar Flow Rate = 8.713 x 10

-3

mol/s

Mole Fraction of C3H8 = (2.76042 x 10

-4

mol/s)/ (8.713 x 10

-3

mol/s) = 0.0317

Mole Fraction of O2 = (1.772 x 10

-3

mol/s)/ (8.713 x 10

-3

mol/s) =

0.2033

Mole Fraction of N2 = (6.665 x 10

-3

mol/s)/ (8.713 x 10

-3

mol/s) =

0.7650

6.3.9 Outlet Molar Flow Rate and Mole Fraction

Outlet Molar Flow Rate = n(CO2 + H2O + N2 + O2)

Outlet Molar Flow Rate = 0.009144215

Mole Fraction of CO2 = 0.09056272

Mole Fraction of H2O = 0.120750293

Mole Fraction of N2 = 0.728898007

Mole Fraction of O2 = 0.05978898

6.3.10 Enthalpies (Hi) of Outlet Stream

State Reference for enthalpies would be respective

components at 25

O

C, 1 atm

Enthalpies of Components =

Carbon Dioxide (CO2):

Hf of CO2 =

Hf of CO2 = - [36.11 x 10

-3

T + 4.233 x 10

-5

] (UL: 903.15, LL:

298.15)

Hf of CO2 = + 16.96748504 kJ/mol = 16.967kJ/mol

Water (H2O):

Hf of H2O = -285.8kJ/mol +

Hf of H2O = -285.8kJ/mol + [33.46 x 10

-3

T + 0.6680 x 10

-5

] (UL:

903.15, LL: 298.15)

Hf of H2O = 13.13196544 kJ/mol = 13.132 kJ/mol

Nitrogen (N2):

Hf of N2 =

Hf of N2 = [29.00 x 10

-3

T + 0.2199 x 10

-5

] (UL: 903.15, LL:

298.15)

Hf of N2 = 11.08011351 kJ/mol = 11.080 kJ/mol

Oxygen (O2):

Hf of O2 = 0 kJ/mol +

Hf of O2 = [29.61 x 10

-3

T + 1.158 x 10

-5

] (UL: 903.15, LL:

298.15)

Hf of O2 = 12.06077904 kJ/mol = 12.061 kJ/mol

6.3.11 Higher Heating Value (HHV)

The value is determined by bringing all the products of

combustion back to the original pre-combustion temperature,

and the condensation of any vapor produced. The reference

temperature utilized is 25 C which is the same as the

thermodynamic heat of combustion; since the enthalpy change

for the reaction assumes a common temperature of the

compounds before and after combustion, in which case the water

produced by combustion is liquid. The higher heating value also

takes into account the latent heat of vaporization of water.

HHV = LHV + Latent Heat of Vaporization of H2O

HHV = -(Hc)

HHV = 2220.0kJ/mol

6.3.12 Lower Heating Value (LHV)

The value is determined by subtracting the heat of vaporization

of the water vapor from the higher heating value which treats any

H2O formed as a vapor. This methodology assumes that the water

component of a combustion process is in vapor state at the end of

combustion, as opposed to the higher heating value where all of

the water in a combustion process is in a liquid state after a

combustion process.

LHV = -(Hc + Latent Heat of Vaporization of H2O )

LHV = - (-2220.0kJ/mol + 44.013kJ/mol) = 2175.99 kJ/mol

6.3.13 Heat Rejection of Combustion Chamber (Q)

First Law for Open System at Steady State:

Q + Ws = H + Ek + Ep

Q = H = out niHi - in niHi + Hc (heat of reaction method)

Q = [nCO2HCO2 + nH2OHH2O + nN2HN2 + nO2HO2] [nC3H8HC3H8 + nO2HO2

+ nN2HN2] + Hc

Q = [(16.967 kJ/mol)(8.281 x 10

-4

mol/s) + (13.132

kJ/mol)(1.104 x 10

-3

mol/s) + (11.080 kJ/mol)(6.665 x 10

-3

mol/s) + (12.061 kJ/mol)(5.467 x 10

-4

mol/s)] [( 0

kJ/mol)(2.760 x 10

-4

mol/s)] + [(-2220 kJ/mol)( 2.760 x 10

-4

mol/s)]

Q = -0.503816339 kJ/s = - 503.816 J/s

The negative result signifies that heat rejected from the system,

releasing energy in a form of heat. The above method makes use

of Hess Law which can be found in Appendix B.

6.3.14 Percentage of Air Excess Ratio (Nitrogen Gas Based)

Percent Excess Air = [(moles air)fed - (moles air)theo]/[(moles

air)theo] x 100%

Percent Excess Air = [(8.437 x 10

-3

mol/s) - (5.834 x 10

-3

mol/s)]/

[(5.834 x 10

-3

mol/s)]

Percent Excess Air = 44.63%

The Percent Excess Air obtained is 44.63%. This implies that the

air to fuel ratio is sufficient for complete combustion of the

propane gas. Also, based on the gas chromatography, there were

no evident peaks depicting the presence of Carbon Monoxide;

only to prove that total complete combustion has occurred.

However, this assumes that extent of reaction is 100 percent,

using the amount of reacted O2 as the theorectical moles of O2.

7. Discussion

7.1 Methodology

For this study, the fireboy burner was used as the combustion

chamber and the Gas Chromatogram was used to test the outlet

air sample using the aid of micro-syringe to capture the air

sample. Overall, it was a relatively easy method of getting fast

results to do quick and easy calculations. However, each step has

its cons as well, with sources for error, leading to a less accurate

study.

Fireboy Burner

The fireboy burner has a tube-like combustion chamber and is a

safe and easy way of burning fuel, with the inlet components

flowing in from the bottom and the residual gas leaving at the top

of the tube.

Source(s) of error and recommendation:

However, the top of the tube has a sufficiently large diameter

making it difficult to take a sample that represents the outlet gas

as its constituents might not be homogenous and uniform

throughout the area at the top of the tube, for the the sampling

using the micro-syringe. Hence, a possible suggestion might

actually be using a smaller diameter tube-like combustion

chamber to minimise this non-homogeneity discrepancy. The air

samples can also be taken at a specific spot around the top of the

tube to emphasise on consistancy and accuracy of results, if more

than one air samples are to be taken.

Micro-syringe air sampling

Air sampling is a fast and convenient way of collecting air for

measurement of air ratios. The micro-syringe is light and

features a lock to collect and seal off the air compartment

effectively. However, the technique of using air samples to

represent the whole of the residual gas from the combustion

chamber gives room from a sources of error. Techniques of using

the microsyringe also has its limitations.

Source(s) of error & recommendation:

First, the study was conducted using only one air sample to

represent the outlet gas mixture. A rough estimation of after 3

mins after the combustion process started was given before it

was assumed to be at steady state. Using only one air sample

does not give confirmation that combustion has already reached

steady state. It was still possible that the outlet air ratio could be

changing when the air sample was taking. Hence, it is highly

recommended that for future experiments, there should be

multiple trials to monitor the state of the combustion process.

Also, a larger volume of sample could be utilized, producing a

more effective and reliable result.

In addition to that, due to safety reasons, the air sample was not

taken directly from the outlet of the combustion chamber, but

instead at a distance to prevent the risk of getting burned. Thus,

this proves to be a significant source of error, simply due to the

fact that the air taken was not completely from the outlet to the

combustion chamber but also partially made up of generic

surrounding air. This thus affects the final reading of the air

mixture ratio on the GC, eventually affeting the sample

calculations. Therefore, a syringe which has a longer tip and

better safety feature could have been used to sample direct air

from the outlet of the tube instead.

Gas Chromatography

The gas chromatogram also is a quick way of determining the air

mixture ratios with the help of an inbuilt Thermal Conductivity

Detector.

This detection process involves carrying the sample gas by

helium or any other inert gas which does not contribute to the

separation process (carrier gas). Due to the difference in

molecular weight and other viable properties, the compounds

will be separated but all different retention timings due to their

nature of molecular structure and interaction with the column.

The mechanism in which the TCD detects is via the electrical

resistance of the sample passing though a wire which has a

constant voltage applied. Any organic vapor of the highly heated

compound that passes through the wire will change the

resistance. This change in resistance is displayed in form of peak

in the graph plotted according to the time when the change of

resistance occurs. This thus, is an effective way in detecting and

determining the different gases in the outlet gas mixture.

This GC process can be done in less than 20 mins to display not

only figures of the air mixture ratio but also a curve that shows

relatively the peaks of the constituent gases. Below is a picture

taken of the curve from the experiment.

Fig 4: Curves computed from the GC analysis

The image above shows two curves; one in pink which

represents the air generic surrounding air and black one

showing the outlet gas constituents. The first peak (furthest left)

shows the relative composition of CO2 gas while the second peak

shows the relative compositions of O2 and N2 gases. This curve

shows that O2 and N2 makes a up majority of the air mixture

constituents, be it being the surrounding air or the residual gas

from the combustion chamber. However, the main significance of

this curve is that it shows clearly the difference for each peaks.

For CO2 , there was hardly a peak for the pink curve while there

is a relatively significant one for the black curve. This shows that

C02 was not present in the inlet air and that was only formed

after the combsution process and comprises a significant portion

of the outlet residual gas. For the second peak, the black one is

lower, implying that the amount of O2 has dropped, as it was one

of the reactants for the combustion process. More about peaks

and curves can be found in Appendix A.

Source(s) of error & Recommendations:

However, the curves also shows that the experiment has sources

of error. Theoretically, the peak of O2 and N2 should be shown as

two separate and distinct peaks, instead of just one large one.

Also, there were some small peaks for the black curve, simply

implying that there were other gas constituents apart from the

ones accounted for in the calculations above. A possible reason

for the source of error is the injection process of the micro-

syringe to the GC, to transfer the air sample into the system to go

through the Thermal Conductivity Detector. The injection

process has to be a quick and swift one so that the air is properly

injected and transferred. A possible recommendation would be

to use a machine to transfer this gas or simply use other means

of transferring the outlet gas for air mixture ratio measurements,

to minimise this discrepancy.

7.2 Calculations and Results

The calculations were relatively straight forward and values

were all derived simply using the mass and energy balances

discussed earlier.

Assumptions used as basis for calculations

From this study, we are able to use the mass and energy

balances, to derive values such as heat output, a useful method

that applies not only to combustion but also other chemical

processes. However, there were quite a few basis of assumptions

we needed to take into account before using the mass and energy

balances, which may affect the actual values of the calculations

above.

The first assumption was that the initial conditions prior to this

experiment was judged to be at standard state condition with

reference to the rooms temperature: 25C and pressure

101.325kPa. This initial condition plays an important role as

reference states of the gaseous constituents are taken at 25

O

C, 1

atm. The reference states allows us to calculate the enthalpies

and acts as a basis these enthalpy calculations, where at

reference states, enthalpies are 0 kl/mol.

In addition, It was assumed that since generic air from the

surroundings was the inlet air, meaning that the composition of

air was with regards to only oxygen and nitrogen. In addition, the

ratio of oxygen to nitrogen is 1 : 3.76. This thus disregards the

presence of other contituents of the generic air such as water

vapor and carbon dioxde, even though their respective mole

fractions are relatively insignificant. The air ratio also was used

to determine the mole fraction of inlet oxygen, thus affecting the

amount of oxygen reacted that was calculated.

Another key assumption was that the reaction had reached

steady state, meaning that there were no change in variables

over time. This assumes that the composition of the air sample at

the outlet was not changing with respect to time and that taking

one air sample and finding its mole ratio was enough. This

assumption also suggests that there was no built up in the

combustion chamber. This assumptions thus allows us to simply

calculate the enthalpies and moles rates easily without taking

into account and variable factors.

The last key assumption was that in the first law of open system

with steady state motion, it was assumed that there was

negligible work, change in potential energy and kinetic energy.

This means that the change in kinetic energy and potential

energy can be disregarded in using the energy balance equation

for open system, which also implies that heat loss or rejected is

equal to enthalphy change of the chemical constituents.

Sources of error & Recommendation:

These assumptions serve as sources of error. When assumptions

are made, the tendency of error increases, depending on the

significance of assumptions. Therefore, to improve the accuracy

of the experiment, the significance of these assumptions can be

tested.

9. Conclusion

In conclusion, methodology used in the experiment has been

simple, effective and successful enough in yielding fast and

positive results to find the air mixture ratio which eventually

enabled us to calculate the many different properties of the input

and output constituents and experiment. Furthermore, the

material and energy balance for a steady-state combustion

process has been formulated, giving a basic understanding of air

excess ratio, stoichiometric, higher heating value and lower

heating value. As an added benefit, the concept of the gas

chromatography was better understood with practicality even

though there was a significant possible source of error using the

injection technique of the micro-syringe and quite a handful of

assumptions have to be made. Of course, this experiment is only

one of the many methods that can be used. To have a better

understanding of the combustion process and deriving the

calculated values, other methods such as mass spectrometry

(Appendix C) can be used in conjuction with GC to further back

up the assumptions and minimise uncertainty of the derived

values.

10. References

[1] Mass Spectrometry , Retrieved 8 March, 2014 from

http://www.premierbiosoft.com/tech_notes/mass-

spectrometry.html

[2] Fundamentals of Gas Chromatography, Retrived 8 March, 2014,

from

http://www.chem.agilent.com/Library/usermanuals/Public/G

1176-90000_034327.pdf

[3] Hess Law Conservation of energy , Retrived 8 March, 2014,

from

http://www.science.uwaterloo.ca/~cchieh/cact/c120/hess.ht

ml

11. Appendix

11.1 Appendix A Gas Chromatography

11.11 Gas Chromatography

[2]

Gas chromatography (GC) is a laboratory technique that

separates mixtures into individual components. It is used to

identify components and to measure their concentrations.

Rather than a physical separation (such as distillation and

similar techniques), GC creates a time separation.

It does this by passing the vaporized mixture (or a gas) through

a tube containing a material that retards some components

more than others. This separates thc components in time. After

detection, the result is a chromatogram (Figure 1), where each

peak represents a different component of the original mixture.

The appearance time can be used to identify each component;

the peak size (height or area) is a measure of the amount.

A gas chromatographic system consists of:

A regulated and purified carrier gas source, which moves the

sample through the GC

An inlet, which also acts as a vaporizer for liquid samples

A column, in which the time separation occurs

A detector, which responds to the components as they occur

by changing its electrical output

Data interpretation of some sort

Fig 5: Components of the GC

[3]

11.12 Peak Measurements

[2]

Two basic measurements can be made on a peak:

The time after injection when the peak is detected

The size of the peak

Retention time

The appearance time, measured from injection to detection, is

the sum of two parts:

The plumbing timehow long it takes for the carrier gas to

pass through the column. It is measured by injecting air or

some other non-interacting substance.

The retention timethe additional time caused by the

components interaction with the stationary phase in the

column.

For most purposes, the plumbing time is ignored and the

retention time is taken as the appearance time.

Peak size

Size can be measured either as peak area or peak height, both

measured relative to a constructed baseline.

The baseline under the peak cannot be measured directly. It

must be constructed from the baselines on either side of the

peak.

This is simple with well-separated peaks. It is much more

difficult when peaks are merged, on the trailing edge of a

solvent peak, or otherwise less than ideal. For this reason, time

spent improving the peak separation is time well spent.

Peak height

This is the simplest measurement, requiring only a ruler. It is

the vertical distance from the top of the peak to the baseline.

Peak area

This is the area enclosed by the peak signal and the baseline

under it. It is best measured by electronic means.

11.2 Appendix B Hess Law

[3]

Hess's law states that energy changes are state functions. The

amount of energy depends only on the states of the reactants and

the state of the products, but not on the intermediate steps.

Energy (enthalpy) changes in chemical reactions are the same,

regardless whether the reactions occur in one or several steps.

The total energy change in a chemical reaction is the sum of the

energy changes in its many steps leading to the overall reaction.

11.3 Appendix C Mass Spectrometry

[1]

Mass spectrometry is a powerful analytical technique used to

quantify known materials, to identify unknown compounds

within a sample, and to elucidate the structure and chemical

properties of different molecules. It generates multiple ions from

the sample under investigation, it then separates them according

to their specific mass-to-charge ratio (m/z), and then records the

relative abundance of each ion type. Similar to the GC,the Mass

Spectrometer identifies the different components to give a curve.

Fig 6: Components of Mass Spectrometry

[1]