100% found this document useful (1 vote)

550 views19 pagesChem Eng Process Control Intro

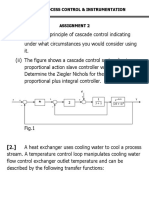

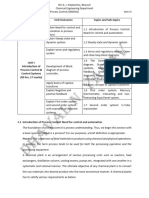

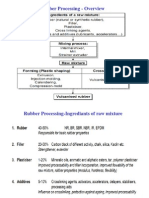

This document provides an outline for the CHE334 Instrumentation and Process Control unit. It introduces the topics that will be covered, which include fundamentals of instrumentation, basic control theory, and common measurement techniques. Assessment will include two sessional tests, quizzes, assignments, and a final exam. Chapter 1 will introduce process control, instrumentation, basic concepts like systems and control loops, and components of measurement and control systems. The goal of process control is to safely and satisfactorily operate chemical processes through automation. Controllers are used to suppress external disturbances and ensure safety while optimizing performance and reducing variability.

Uploaded by

Tamoor TariqCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

550 views19 pagesChem Eng Process Control Intro

This document provides an outline for the CHE334 Instrumentation and Process Control unit. It introduces the topics that will be covered, which include fundamentals of instrumentation, basic control theory, and common measurement techniques. Assessment will include two sessional tests, quizzes, assignments, and a final exam. Chapter 1 will introduce process control, instrumentation, basic concepts like systems and control loops, and components of measurement and control systems. The goal of process control is to safely and satisfactorily operate chemical processes through automation. Controllers are used to suppress external disturbances and ensure safety while optimizing performance and reducing variability.

Uploaded by

Tamoor TariqCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 19