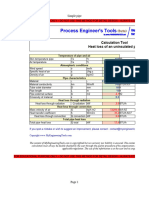

COLD INSULATION THICKNESS CALCULATION

S.No

Description

Formulae

Unit

Value

Input

Table.1

Ambient temperature

Ta

35.8

2

3

4

Operating temperature

Relative humidity

Emissivity of surface(Aluminium dull finish)

5

6

Wind velocity

Diameter of Shell

To

Rh

Vw

C

%

-34

85

0.3

m/s

mm

0.5

250

Insulation material selected

8

9

Type of Heat Exchanger (Shape & condition)

Insulation thickness assumed for Iteration

Poly urethane

Horizontal Plates, cooler than

t

inch

mm

m

3.37

85.5980

0.085598

mm

inch

o

F

o

F

273.1

10.924

96.44

-29.2

7

Shape and Condition

Horizontal Cylinders

Long Vertical Cylinders

Vertical Plates

Horizontal Plates, Warmer than air Facing upward

Horizontal Plates, Warmer than air Facing downward

Horizontal Plates, Cooler than air Facing upward

Horizontal downward

Plates, cooler than air Facing downward

air Facing

Sphere

C Values

1.016

1.235

1.394

1.79

0.89

0.69

1.79

1.8159

CALCULATION

10

Outside diameter of shell

d0

11

12

Ambient temperature

Operating temperature

13

14

Wind velocity

Dew point corresponding to Ambient & Rh

Ta

To

Vw

15

Minimum surface temperature over

insulation to prevent condensation

TDP

16

17

18

Heat gain by Radiation as per Stefan-Boltzmann

Average absolute temperature

Temperature difference

19

20

Diameter over Insulation

C value corresponding to the type of heat exchanger

ft/min

o

C

98.4

32.8

91.09

33.38

1.26

92.09

1.22

Btu/ft2/h

o

R

o

F

1.543

553.9

4.35

10

12

14

1.19

1.15

1.1

inch

17.5

1.79

16

18

1.08

1.06

20

22

1.04

1.07

Ts = TDP + 1

Qr = 0.174*10-8*E*

[(Ta+459.6)4-(Ts+459.64)4]

T = (Ta+Ts)/2

T= Ta-Ts

=do+2(t)

C

from table.1

22

Qca = C * (1/d)0.2 *

Heat gain by Convection as per Heilman's equation

(1/T)0.181 * (T)1.266

(Modification of Langmuir Eqn)

Btu/ft2/h

1.103

d = O.D of cylindrical surface or height of vertical flat surface(for anything 24" or more use values listed for 24)=24

Multiplication factor for diameter over

from Table 2

1.065

insulation from Thermal Insulation handbook

23

Revised heat gain by convection for Insulation over shell

24

25

Revised heat gain by convection for wind velocity

Hence Surface heat gain

26

27

28

Thermal Resistance

Thermal Conductivity of Insulation material

Calculated Thickness of Insulation

29

Outer radius of shell

R = (Ts-To)/Q

K,

from data - I/p

T= R * K

r1= do/(2)

30

Radius over insulation

ro = r1 + t

31

Iterating Equivalent thickness of insulation for pipelines

such that Eq.thk > thk. Of insln. For flat surface

t1 = ro*ln(ro/r1)

32

Sufficiency of thickness

21

Qca'=Qca * Multipli.factor

Qca"=Qca'

*((Vw+68.9)/68.9)0.5

Q = Qr + Qca"

Table.2

INCHES

1

2

4

6

Btu/ft2/h

Btu/ft2/h

Btu/ft2/h

kcal/m2/h

m2hoC/kcal

kcal/mhoC

m

1.174

1.8298

3.372

9.139

7.373

0.01462

0.1078

0.137

0.222

m

if t1 < T, Assumed thk. Is sufficient

0.108109

OK

MULTIPLICATION FACTOR

1.83

1.64

1.43

1.37

��HOT INSULATION THICKNESS CALCULATION

S.No

1

2

3

4

5

6

7

8

Description

Input

Ambient temperature

Surface temperature

Emissivity of surface

Wind velocity

Formulae

Unit

Ta

Ts

Vw

Value

30

60

0.3

m/s

kg/m3

o

25

40

50

33.4

48.3

60.3

65

80

73

88.9

100

114.3

125

141.3

150

200

168.3

219.1

303

8

9

10

250

273.1

355.6

11

300

323.9

333

12

350

355.6

350

mm

OD

300.0

Gr 3 ( 81-120 kg/m3)

10

thk selection

NB

2

3

4

5

6

Insulation material selected

Density of mineral wool

Operating temperature

To

12

cell link

S.No

Nominal diameter of the pipe

Calculation

Ambient temperature

Ta

10

Outside Diameter of pipe

do

11

Surface temperature

Ts

12

Heat loss thro' radiation

Qr

=(4.876*10-8)**(Ts4-Ta4)

Kcal/sqm.hr

56.573

13

400

406.4

13

14

15

Heat loss thro' convection

Allowable heat loss from insulation

Surface film co-efficient

Qc

Q

F

=1.683*(Ts-Ta)1.25*((2.857Vw)+1)0.5

Kcal/sqm.hr

Kcal/sqm.hr

Kcal/sqm.hr

232.065

288.639

9.621

450

500

550

457.2

508

558.8

16

Mean temperature

=(Ts+To)/2

180

600

609.6

17

Thermal Conductivity at mean temperature K

From table

o

C

Kcal/sqm.hr

deg.C

14

15

16

17

0.3956

18

19

Heat loss thro' calculation

Selected thickness by iteration

20

Select nearest available thickness

Kcal/sqm.hr

m

mm

mm

218.263

0.2878

287.8198

300

mm

K

= Qr +Qc

= Q/(Ts-Ta)

=

(To-Ta) /

((((do+2t)/2k)*ln((do+2t)/do))+(1/F))

=if((Ts>To),0,(K*((To-Ta)/Q)-(1/F)))

Thermal Conductivity - mW/cmoC

Mean temperature - oC

1

50

0.49

0.43

0.43

0.43

3

Gr 1 ( 12-50 kg/m3)

Gr 2 ( 51-80 kg/m3)

Gr 3 ( 81-120 kg/m3)

Gr 4 ( 121-160 kg/m3)

3

150

1

2

3

4

4

200

180

2

100

0.69

0.52

0.52

0.52

3

150

0.95

0.64

0.62

0.62

4

200

----0.78

0.73

0.68

5

250

----0.93

0.84

0.8

6

300 Max temp.

----250

1.1

400

0.95

550

0.9

750

4.6