0% found this document useful (0 votes)

489 views10 pagesSlip Form Constuction.

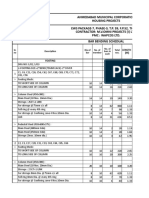

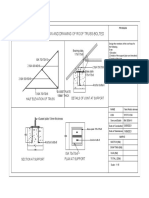

This document discusses slipform construction, a method for building tall concrete structures like core walls in high-rise buildings. Slipform construction involves a moving form that concrete is continuously poured into. As the concrete hardens, the form slides upwards, eliminating the need for cranes or scaffolding. It allows for fast, continuous construction. The key is using concrete that can gain early strength quickly to support the rising form. Benefits include high production rates, minimizing equipment needs, and improving safety with integrated working platforms. Extensive planning is required to control concrete properties and match the form's movement.

Uploaded by

Akshay JangidCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

489 views10 pagesSlip Form Constuction.

This document discusses slipform construction, a method for building tall concrete structures like core walls in high-rise buildings. Slipform construction involves a moving form that concrete is continuously poured into. As the concrete hardens, the form slides upwards, eliminating the need for cranes or scaffolding. It allows for fast, continuous construction. The key is using concrete that can gain early strength quickly to support the rising form. Benefits include high production rates, minimizing equipment needs, and improving safety with integrated working platforms. Extensive planning is required to control concrete properties and match the form's movement.

Uploaded by

Akshay JangidCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 10