PROCESSDESIGNCALCULATIONSFOR1.

0MLDCAPACITYSEWAGEPUMPINGSTATION(SPS)

DESIGNPARAMETERS:

AverageFlow(Qav)

1.00 MLD

41.7 m3/hr

0.012 m3/sec

PeakFlow(Qpk)

3.00 MLD

125 m3/hr

0.035 m3/sec

PeakFlowFactor=(Qpk/Qav)

3.00

INLETCHAMBER:

UnittobedesignedforPeakFlow

3.00 MLD

125.0 m3/hr

0.035 m3/sec

andtobecheckedforAverageFlow

1.00 MLD

41.7 m3/hr

0.012 m3/sec

CapacityofStillingChamber

Volumerequired

=

=

0.035 x30

1.04 m3

ProvidingSWD

0.60 m

LengthProvided

1.60 m

WidthProvided

1.20 m

ProvidingFreeboard

0.50 m

VolumeProvided

1.15 m3

OK

1600 Long

600 SWD

ProvideStillingChamberof

30 seconpeakflow

1200 wide

COARSESCREENCHANNELS:

No.ofunitstobeprovided

2 Nos.

(1MechanicalW+1MechanicalS)

UnittobedesignedforPk.Flow

3.00 MLD

125.0 m3/hr

0.035 m3/sec

andtobecheckedforAvg.Flow

1.00 MLD

41.6667 m3/hr

0.012 m3/sec

MechanicalScreenChannel

�PROCESSDESIGNCALCULATIONSFOR1.0MLDCAPACITYSEWAGEPUMPINGSTATION(SPS)

ATPALI,RAJASTHAN

Astherewillbeonestream,

DesignFlowatPeakCondn

0.035

1

3

m /sec

0.035 m3/sec

DesignFlowatAvg.Condn

0.012

1

m /sec

0.012 m3/sec

0.035 m2

0.02315 m2

0.042 m2

VelocitythruScreenChannelfor:

Qpk =

Qavg =

1.0 m/s

0.5 m/s

Areaofscreenchannelreqd.forQpk

0.035

1

m /sec

m/s

Areaofscreenchannelreqd.forQavg

0.012

0.5

m /sec

m/s

Considering50mmopeningand10mmthicknessofbars,

Grossarearequired

0.035 x60

50

Assumingwidthofchannelas

600 mm

Widthofsideframeoneachside

0 mm

Totalwidthofchannel

600 mm

Liquiddepthinscreen

69 mm

Heightofdeadplate

500 mm

Totaldepthofscreen

600 mm

Angleofinclinationwithhorizontol

45 Deg

ProvidelengthofScreenChamberas

6.00 m

Providefreeboardas

300 mm

Say

100 mm

Say

600 mm

onupstreamside

�PROCESSDESIGNCALCULATIONSFOR1.0MLDCAPACITYSEWAGEPUMPINGSTATION(SPS)

ATPALI,RAJASTHAN

ProvideScreenChannelof

600 wide

600 SWD

CheckforHeadlossinscreen

Headlossthruscreenundercleanconditions

HL=0.0729(V12V22)

Netareaavailablethruscreen

Velocitythruscreenatpeakflow(V1)

0.6 x0.1x50

x60

2

= 0.050

= 0.035

0.050

m/s

0.694 m/s

0.035

0.6 x0.6

0.096 m/s

0.034 m

Velocitythruscreenatpeakflow(V1)

1.389 m/s

Approachvelocityatpeakflow(V2)

0.035

0.60 x0.6

0.096 m/s

0.140 m

Approachvelocityatpeakflow(V2)

Headloss(HL)

34.48 mm

140 mm

Headlossthruscreenunderhalfclogged

conditions

HL=0.0729(V12V22)

Headloss(HL)

COLLECTINGTANK

6000 Long

�PROCESSDESIGNCALCULATIONSFOR1.0MLDCAPACITYSEWAGEPUMPINGSTATION(SPS)

ATPALI,RAJASTHAN

UnittobedesignedforPeakFlow

CapacityofCollectingTank

Volumerequired

=

=

0.035 x20

41.67 m3

ProvidingSWD

2.00 m

Diameterrequired

5.15 m

DiameterProvided

5.20 m

VolumeProvided

42.47 m3

OK

ProvideCollectingTankofsize

3.00 MLD

125.0 m3/hr

20 minutesonpeakflow

5200 dia

x 60

2000 SWD

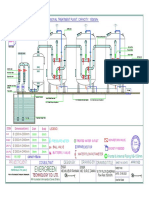

PumpingMachineryinCollectingTank

Typeofpumps

= Nonclogsewagesubmersible

TotalFlow

125 m3/hr

Diaofpumpingmain(aspertender)

250 mm

LengthofpipefromSPStomanhole

500 m

FrictionalLosses

2.0 m

StaticHead

9.0 m

OtherMiscellaneousLosses@20%

2.2 m

Terminalheadrequired

1.0 m

TotalHeadrequired

14.2 m

Numberofpumps,fordischarge0.86MLD

Say

0.035 m3/sec

16 m

2 Dischargeperpump=

9.95 LPS

0.035 m3/sec

�PROCESSDESIGNCALCULATIONSFOR1.0MLDCAPACITYSEWAGEPUMPINGSTATION(SPS)

ATPALI,RAJASTHAN

HPrequiredbyPump

= 9.95x16/0.7/75

=

3.03 HP

Say

Numberofpumps,fordischarge0.43MLD

HPrequiredbyPump

= 4.98x/0.7/75

=

1.52 HP

3.3 HP

2 Dischargeperpump=

Say

1.7 HP

4.98 LPS

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

DESIGNPARAMETERS:

AverageFlow(Qav)

=

15.00 MLD

=

625.0 m3/hr =

0.174 m3/sec

PeakFlowFactor=(Qpk/Qav)

2.25

PeakFlow(Qpk)

33.75 MLD

BiologicalOxygenDemand(BOD5)

300 mg/l

ChemicalOxygenDemand(COD)

650 mg/l

TotalSuspendedSolids(TSS)

600 mg/l

FecalColiform

= 1x104

TotalKjeldahlNitrogen(TKNasN)

55 mg/l

TotalPhosphorous(TP)

6 mg/l

1406.25 m3/hr

0.391 m3/sec

QUALITYOFINLETWASTE:

MPN/100ml

OUTLETSTANDARDSREQD.:

BiologicalOxygenDemand(BOD5)

= <10

mg/l

ChemicalOxygenDemand(COD)

= <100

mg/l

TotalSuspendedSolids(TSS)

= <10

mg/l

FecalColiform

= <230

MPN/100ml

TotalNitrogen(asN)

= <10

mg/l

TotalPhosphorous(TP)

= <1

mg/l

INLETCHAMBER:

UnittobedesignedforPeakFlow

33.75 MLD

1406.3 m3/hr

0.391 m3/sec

andtobecheckedforAverageFlow

15.00 MLD

625.0 m3/hr

0.174 m3/sec

CapacityofStillingChamber

Volumerequired

=

=

30 seconpeakflow

0.391 x30

11.72 m3

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

ProvidingSWD

=

1.00 m

LengthProvided

4.00 m

WidthProvided

3.00 m

ProvidingFreeboard

0.50 m

VolumeProvided

12.00 m3

OK

ProvideStillingChamberof

3000 wide

4000 Long

1000 SWD

COARSESCREENCHANNELS:

No.ofunitstobeprovided

2 Nos.

(1mechanicalW+1MechnaicalS)

UnittobedesignedforPk.Flow

33.75 MLD

1406.3 m3/hr

0.391 m3/sec

andtobecheckedforAvg.Flow

15.00 MLD

625 m3/hr

0.174 m3/sec

MechnicalScreenChannel

Astherewillbeonestream,

DesignFlowatPeakCondn

0.391

1

m3/sec

0.391 m3/sec

DesignFlowatAvg.Condn

0.174

1

m3/sec

0.174 m3/sec

VelocitythruScreenChannelfor:

Qpk =

Qavg =

1.0 m/s

0.5 m/s

Areaofscreenchannelreqd.forQpk

0.391

1

m3/sec

m/s

0.391 m2

Areaofscreenchannelreqd.forQavg

0.174

0.5

m3/sec

m/s

0.34722 m2

0.469 m2

Considering50mmopeningand10mmthicknessofbars,

Grossarearequired

0.391 x60

50

Assumingwidthofchannelas

1000 mm

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

Widthofsideframeoneachside

0 mm

Totalwidthofchannel

1000 mm

Liquiddepthinscreen

469 mm

Heightofdeadplate

500 mm

Totaldepthofscreen

970 mm

Angleofinclinationwithhorizontol

45 Deg

ProvidelengthofScreenChamberas

7.00 m

Providefreeboardas

500 mm

ProvideScreenChannelof

Say

470 mm

Say

1000 mm

onupstreamside

1000 wide

1000 SWD

61.39 mm

CheckforHeadlossinscreen

Headlossthruscreenundercleanconditions

HL=0.0729(V12V22)

Netareaavailablethruscreen

Velocitythruscreenatpeakflow(V1)

Approachvelocityatpeakflow(V2)

Headloss(HL)

Headlossthruscreenunderhalfclogged

conditions

HL=0.0729(V12V22)

1 x0.47x50

x60

= 0.392

m2

= 0.391

0.392

m/s

0.997 m/s

0.391

1 x1

0.391 m/s

0.061 m

7000 Long

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

Velocitythruscreenatpeakflow(V1)

=

1.995 m/s

Approachvelocityatpeakflow(V2)

0.391

1.00 x1

0.391 m/s

0.279 m

279 mm

UnittobedesignedforPeakFlow

33.75 MLD

1406.3 m3/hr

CapacityofCollectingTank

Volumerequired

=

=

0.391 x20

468.75 m3

ProvidingSWD

2.50 m

Diameterrequired

15.45 m

DiameterProvided

16.00 m

VolumeProvided

502.65 m3

OK

Headloss(HL)

COLLECTINGTANK

ProvideCollectingTankofsize

20 minutesonpeakflow

16000 dia

x 60

2500 SWD

PumpingMachineryinCollectingTank

Typeofpumps

= Nonclogsewagesubmersible

TotalFlow

1406.25 m3/hr

Numberofworkingpumps

Numberofstandbypumps

Dischargeperpump

703.125 m3/hr

11719 LPM

11.5 m

StaticHead

195.3 LPS

0.391 m3/sec

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

MiscLosses@20%

=

2.3 m

RequiredHeadofPump

13.8 m

TakeHeadofpump

15.0 m

Numberofpumps,fordischarge15MLD

BHPrequiredbyPump

= 173.61x15/0.7/75

=

49.6 BHP

Say

2 Dischargeperpump=

Numberofpumps,fordischarge7.5MLD

BHPrequiredbyPump

= 86.81x15/0.7/75

=

24.8 BHP

Say

173.61 LPS

54.6 BHP

2 Dischargeperpump=

86.81 LPS

27.3 BHP

STILLINGCHAMBER:

UnittobedesignedforPeakFlow

33.75 MLD

1406.3 m3/hr

0.391 m3/sec

andtobecheckedforAverageFlow

15.00 MLD

625.0 m3/hr

0.174 m3/sec

CapacityofStillingChamber

Volumerequired

=

=

0.391 x30

11.72 m3

ProvidingSWD

2.00 m

LengthProvided

3.00 m

WidthProvided

2.00 m

ProvidingFreeboard

0.50 m

VolumeProvided

12.00 m3

OK

3000 Long

2000 SWD

ProvideStillingChamberof

30 seconpeakflow

2000 wide

FINESCREENCHANNELS:

No.ofunitstobeprovided

2 Nos.

33.75 MLD

(1MechanicalW+1MechanicalS)

MechanicalScreenChannel

UnittobedesignedforPk.Flow

1406.3 m3/hr

0.391 m3/sec

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

andtobecheckedforAvg.Flow

15.00 MLD

625 m3/hr

0.174 m3/sec

7000 Long

Astherewillbeonestream,

DesignFlowatPeakCondn

0.391

1

m3/sec

0.391 m3/sec

DesignFlowatAvg.Condn

0.174

1

m3/sec

0.174 m3/sec

VelocitythruScreenChannelfor:

Qpk =

Qavg =

1.0 m/s

0.3 m/s

Areaofscreenchannelreqd.forQpk

0.391

1

m3/sec

m/s

0.391 m2

Areaofscreenchannelreqd.forQavg

0.174

0.3

m3/sec

m/s

0.5787 m2

0.868 m2

Considering6mmopeningand3mmthicknessofbars,

Grossarearequired

0.579 x9

6

Assumingwidthofchannelas

1100 mm

Widthofsideframeoneachside

150 mm

Totalwidthofchannel

1400 mm

Liquiddepthinscreen

789 mm

Heightofdeadplate

50 mm

Totaldepthofscreen

850 mm

Angleofinclinationwithhorizontol

40 Deg

ProvidelengthofScreenChamberas

7.00 m

Providefreeboardas

300 mm

ProvideScreenChannelof

CheckforHeadlossinscreen

1400 wide

800 mm

850 mm

onupstreamside

x

850 SWD

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

Headlossthruscreenundercleanconditions

HL=0.0729(V12V22)

Netareaavailablethruscreen

Velocitythruscreenatpeakflow(V1)

1.1 x0.8x6

x9

= 0.587

m2

= 0.391

0.587

m/s

0.666 m/s

0.391

1.4 x0.85

0.328 m/s

0.024 m

Velocitythruscreenatpeakflow(V1)

1.332 m/s

Approachvelocityatpeakflow(V2)

0.391

1.40 x0.85

0.328 m/s

0.121 m

Approachvelocityatpeakflow(V2)

Headloss(HL)

24.46 mm

121 mm

Headlossthruscreenunderhalfclogged

conditions

HL=0.0729(V12V22)

Headloss(HL)

GRITREMOVALUNIT:

No.ofunitstobeprovided

2 Nos.

UnittobedesignedforPk.Flow

33.75 MLD

SurfaceOverflowRate

(1MechanicalW+1MechanicalS)

MechanicalGritChamber

=

959 m3/day/m2

1406.3 m3/hr

0.391 m3/sec

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

PlanArearequired

=

35.19 m2

Lengthrequired

6m

Widthprovided

6m

AreaProvided

36 m2

HRTatpeakFlow

1 min

VolumeRequired

SWDRequired

Say

VelocitythruGritChannel

Say

6m

OK

23.44 m3

0.65111 m

0.7 m

ProvideMechanicalGritChambersof

0.09 m/sec

6000 wide

6000 Long

SBRREACTORS:

CalculationsforSBRReactorsshallbeprovidedbythetechnologyprovider.

CHLORINECONTACTTANK:

Volumeofsewagetreated

DesignretentiontimeinCCT

30 min

VolumeofChlorinationtank

625 x30

60

15.00 MLD

312.50 m3

ProvidingSWD

3.0 m

DiaProvided

11.6 m

Volumeprovided

ProvidingFreeboard

ProvideChlorineContactTankofsize

CHLORINATOR:

625.0 m3/hr

317.05 m3

OK

0.5 m

11600 dia

3000 SWD

700

SWD

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

Treatedsewageflowrate

=

625 m3/hr

Designchlorinedosage(forchlorinator

capacityonly)

5 ppm

Numberofchlorinators

1 nos.Working+

Chlorinedosagerate

625 x5

1 x1000

3.13 Kg/hr

Chlorinatorcapacityoffered

3.5 Kg/hr

NumberofStandbychlorinators

1 nos.

Totalnumberofchlorinators

2 nos.

Consumptionofchlorinegas

75 kg/day

No.ofChlorineTonnersprovided

1 nosstandby

2250 kg/month

3 Nos

COMMONTREATEDEFFLUENTCHAMBER:

Treatedsewageflowrate

625.0 m3/hr

Designretentiontimeineffuentchamber

30 min

Volumeoftreatedeffuentchamber

625 x30

60

ProvidingSWD

3.0 m

DiaProvided

11.6 m

Volumeprovided

ProvidingFreeboard

ProvideEffuentTreatedChamberofsize

317.05 m3

312.50 m3

OK

0.5 m

11600 dia

PumpingMachineryinEffuentChamber

Typeofpumps

= CentrifugalPump

DecantFlow

1250.0 m3/hr

3000 SWD

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

Numberofworkingpumps

Numberofstandbypumps

Dischargeperpump

625 m3/hr

10417 LPM

StaticHead

27.2 m

MiscLosses@20%

5.44

RequiredHeadofPump

32.64

ProvideHeadofpump

HPrequiredforthepump

= 173.6x33x0.746

75x0.7

173.6 LPS

Say

96.5 HP

33.0 m

87.7 BHP

TotalSludgeasperCTECHcalculations

4763 kg/day

SludgeConsistency

DensityofSludge

VolumeofSludge

=

=

SLUDGECALCULATIONS:

0.80%

1050 kg/m3

4763x

100

567.0 m3/day

0.8/

24.0

SLUDGESUMP(SLUDGEHOLDINGTANK):

HydraulicRetentionTimeofTank

6 hours

Quantityofsludgeproducedinaday

Volumerequired

=

=

567.0

x6

141.80 m3

ProvidingSWD

2.50 m

ProvideDia

8.50 m

567.0 m3/day

1050

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

VolumeProvided

=

141.86 m3

OK

ProvidingFreeboard

ProvideSludgeHoldingTankofSize

0.5 m

8500 Dia

2500

SLUDGESUMPAIRBLOWER:

141.80 m3

VolumeofSludgeSump

Designairagitation

No.ofworkingblowers

1 No

No.ofstandbyblowers

1 No

Requiredcapacityofblowers

141.8

x1.2

170.2 Nm3/hr

CapacityofBlowersoffered

180 Nm3/hr

HPofairblowerrequired

5.2 HP

1.20 Nm3/hr/m3

CENTRIFUGE&CENTRIFUGEFEEDPUMPS:

567.0 m3/day

Sludgeproducedperday

MaxNumberofhoursofoperation

Sludgeflowrate

47.25 m3/hrs

No.ofworkingcentrifugeconsidered

1 no.

No.ofstandbycentrifugeconsidered

1 no.

Capacityofcentrifugerequired

47.25

1

47.25 m3/hrs

Capacityofcentrifugeoffered

50 m3/hrs

HPofcentrifugedrive

15 HP

12 hoursperday

1.0

SWD

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

ActualWorkinghoursofcentrifuge

=

11.34 hrs/day

12 hrs/day

OK

<

50 m3/hrs

Capacityofcentrifugefeedpumpsoffered

No.ofworkingpumps

1 no.

No.ofstandbypumps

1 no.

StaticHead

HPrequiredforthepump

= 13.89x20x0.746

75x0.4

13.89 LPS

20 m

6.9 BHP

Quantityofsludgetobedewateredinaday

4763 Kg/day

ConsideringPolymerdose

Quantityofpolyrequired

4763 x2

1000

Quantityofpolyrequired

9.526 Kg/day

Consideringstrengthofpolysolution

0.10%

Volumeofpolyelectrolytesolution

9.526

0.10% x1000

Volumeofpolyelectrolytesolution

9.526 m3

Consideringnos.oftanks

Volumeofeachdosingtank

4.76 m3

ConsideringSWDoftank

1.5 m

Length/Widthprovided

1.8 m

ProvidingFreeboard

0.3 m

ProvidePolymerdosingtanksof

Say

7.6 HP

POLYELECTROLYTEDOSINGSYSTEM:

2 Kg/Tonofdrysludge

2 nos

1800 wide

1800 Long

1500 SWD

�PROCESSDESIGNCALCULATIONSFOR15.0MLDCAPACITYSEWAGETREATMENTPLANT(STP)

BASEDONSEQUENTIALBATCHREACTOR(SBR)TECHNOLOGYATPALI,RAJASTHAN

Workinghoursofcentrifuge

11.34 hrs

ReqdcapacityofPolydosingpumps

9.526 x1000

11.34 x1

840.01 Lph

Capacityofpolydosingpumpsoffered

850 LPH

No.ofworkingpumpsforeachtank

1 no.