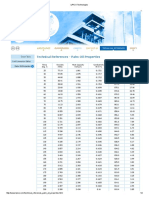

API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

SI UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 1 of 4

By:

Date:

Revision:

As built

For

Site

Oil System for

Supplier

Manufacturer

Purchase Order No.

NOTES:

Date

Inquiry no.

Requisition No.

1. The party to complete the information is indicated as follows:

Purchaser

Vendor

Either, but by vendor if not by purchaser.

2. A dot * indicates the standard specifies a requirement, value, or criterion.

3. Designations in ( ) are applicable portions of the standard; numbers without a prefix are paragraph

numbers; those prefixed T are text figure numbers; those prefixed A are Appendix A Figure

numbers.

NOTE: For definition of General Purpose basic system, see 1.1.1.

Overall system typical schematics:

Figure No.

Option Nos.

Comment

Basic oil supply module

Lube module at equipment

Drawing requirements

Component review

Oil Requirements: See Chapter 1 data sheet (1.2.5, 1.2.7, 1.2.8, 1.2.10, 1.2.11, and 1.2.13)

Baseplate/layout:

Combined with equipment base (1.4.11.2)

Grout hole/vent holes (1.3.5)

Point support (1.3.6)

Epoxy grout/primer pre-coat (1.3.5)

_______ m m min. clearance for components (1.2.12)

Basic system details:

Equipment coast-down time

______

Minimum start-up oil temperature

Sound level

_______

Components:

minutes

______

Shop test conditions

Field start-up/run-in conditions

Db max. (1.2.6)

Welding and special fabrication requirements

All steel external components (1.2.14)

Piping and Tubing:

Tubing fittingsMfg.

_______

Model _______

Carbon steel slip-on flanges not allowed (Table 1D)

Additional special requirements, see

Utilities manifolded to common connections

Through studs required

Heat tracing required by

Valve heads vented to reservoir

Air

Purch.

Vendor

Cooling water

Instrument test valves required

Radiographic examination (2.1.2.2)

Continuous flow transfer valves

Separate for coolers and filters

Tight shutoff required

with lifting jack

Rating: barg

Type

Materials: body

Manufacturer

Plug or ball

Model

Trim

319678935.xlsx

Page 1 of 8, Date Printed: 05/30/2016

�API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

SI UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 2 of 4

By:

Date:

Revision:

As built

Supplier

Manufacturer

Purchase Order No.

Date

Inquiry no.

Requisition No.

Oil conditioners: (if required)

Purchasers item no.

Driver for

Type

HP and enclosure

Portable or mounted on

Volts/PH/Hz

Rated m3/hr of oil

____

____

Manufacturer

Water removal rate

Model

Material of construction

Reservoir (1.4)

____

Pumps and drivers (1.5):

Figures no.

Purchaser item nos.

Include options no.

Full details on data sheet

Electric heater (1.4.7.1)

Pump type and material (1.5.1)

Special heater sizing (1.4.7.1.2)

Supplier standard

Oil level glass (1.4.5.1.4)

ANSI/ASME B73.1 horizontal

Low level alarm (1.4.6.2)

ANSI/ASME B73.2 vertical

50-mm fill opening (1.4.5.1.6)

Rotary positive displacement

Sloped bottom (1.4.4.3)

In-line

Free surfacem2

Submerged

Working capacity (min/liter)

Steel casing (1.2.14)

Retention capacity (min/liter)

API 610

Rundown capacity

Pump quantity and driver(s)

Normal operating range

Single-shaft driven

Charge capacity

Single-motor driven

Insulation clips (1.4.8)

Motor driven start-up w/shaft drive main (1.5.4.1)

Ladder with handrail (1.4.10.1)

Full-sized motor-driven start-up to double

Handrails on top (1.4.10.2)

Dual motor drive

as auxiliary pump (1.5.4)

Non-skid decking (1.4.10.3)

Dual steam turbine main/motor aux. (1.5.4)

Flanged vent

Pump installation

Flanged drain (1.4.4.4)

Removable strainer (1.5.14)

Extra connection (1.4.9)

Mounting pads (1.5.19.1)

Siphon breaker

Top mounted components permitted

Top mounted components are:

Submerged components and materials

Dimensions of tank L x W x H

319678935.xlsx, 3-24

_____

_____

_____

(m)

Page 2 of 8, Date Printed: 05/30/2016

�API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

SI UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 3 of 4

By:

Date:

Revision:

As built

Supplier

Manufacturer

Purchase Order No.

Date

Inquiry no.

Filters:

Requisition No.

Lube oil rundown tanks

Purchaser item no.

Required, yes or no (1.9.1)

Duplex (1.7.3)

Per Figure 2A-13a or 2A-13b (1.9.1)

10 Micron filtration level (1.7.2)

Purchaser item no.

Manufacturer

Capacity (mins)

Model

Capacity (liters)

Design/test (psig)

Code construction/stamp

Material (1.9.1)

Design/test (barg)

Material: case and top

Code construction/stamp for

Cartridges: (1.7.6.3)

2A-13a (1.2.17, 1.9.4)

Thermal relief valves (1.7.3.8)

Nonhydroscopic elements (1.7.6.2)

Furnish _______ extra sets of cartridges.

Coolers:

Type:

None required (1.6.1)

Per filter (extra over other spares).

Single

Connections only for off-base cooler (1.6.1.3)

Shell and tube

Fin fan

Refer to specification

Supplier std.

Plate frame (1.6.1.3)

Purchaser item no(s)

Duty: (Btu/hr) (KW)

Twin units (1.6.1)

Manufacturer

Details on data sheet

Model

Shell and tube:

Water side for steam heating

Design/test shell side (psig)

Water side corrosion allowance

Design/test tube side (psig)

TEMA class

Code construction/stamp (1.2.17)

Fouling factor water/oil side

Tube water velocity and capacity (mps/m3/liter)

Tube: L/OD/BWG

Material: shell

Removable bundle (1.6.3.4.1)

Channels and covers

Oil temperature control valve

Tube sheets and tubes

Thermal relief valve (1.6.1.7)

Removable tube bundle

Continuous flow transfer valves (1.8)

Separate for coolers and filters (1.8.1.1)

Rating: _______ psig

Type

Materials: body

Manufacturer

Plug or ball

Model

Trim

Spectacle blinds (1.8.5)

319678935.xlsx, 3-25

Page 3 of 8, Date Printed: 05/30/2016

�API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

SI UNITS

Applicable to

Proposal

Purchase

Supplier

Purchase Order No.

Job No.:

Item No.:

Page: 4 of 4

By:

Date:

Revision:

As built

Manufacturer

Date

Shop inspection

Inquiry no.

Requisition No.

Shop test

Compliance with inspectors checklist (4.1.1)

Required

Required for system assemblies

Cleanliness

Cleanliness prior to closure

Unit console test (4.3.1.3)

Required for major components

Check controls

Material certifications to be furnished

Changeover filters/coolers

Special examinations

One and two pump operation

Code construction/stamp

Sound level

Certified copies of all test logs and data

Hydro test assembled system

Check pipe strain (4.3.1.4)

Use for complete unit shop test (4.3.1.2)

Pipe radiography (2.1.2.2)

Certified copies of all test logs and data

Witness

Sound level recorded during test

Comments:

319678935.xlsx, 3-26

Page 4 of 8, Date Printed: 05/30/2016

�API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 1 of 4

By:

Date:

Revision:

As built

For

Site

Oil System for

Supplier

Manufacturer

Purchase Order No.

NOTES:

Date

Inquiry no.

Requisition No.

1. The party to complete the information is indicated as follows:

Purchaser

Vendor

Either, but by vendor if not by purchaser.

2. A dot * indicates the standard specifies a requirement, value, or criterion.

3. Designations in ( ) are applicable portions of the standard; numbers without a prefix are paragraph

numbers; those prefixed T are text figure numbers; those prefixed A are Appendix A Figure

numbers.

NOTE: For definition of General Purpose basic system, see 1.1.1.

Overall system typical schematics:

Figure No.

Option Nos.

Comment

Basic oil supply module

Lube module at equipment

Drawing requirements

Component review

Oil Requirements: See Chapter 1 data sheet (1.2.5, 1.2.7, 1.2.8, 1.2.10, 1.2.11, and 1.2.13)

Baseplate/layout:

Combined with equipment base (1.4.11.2)

Grout hole/vent holes (1.3.5)

Point support (1.3.6)

Epoxy grout/primer pre-coat (1.3.5)

_______

ft min. clearance for components (1.2.12)

Basic system details:

Equipment coast-down time

minutes

Minimum start-up oil temperature

Sound level

_______

Components:

Shop test conditions

Field start-up/run-in conditions

Db max. (1.2.6)

Welding and special fabrication requirements

All steel external components (1.2.14)

Piping and Tubing:

Tubing fittingsMfg.

_______

Model

_______

Carbon steel slip-on flanges not allowed (Table 1D)

Additional special requirements, see

Utilities manifolded to common connections

Through studs required

Heat tracing required by

Valve heads vented to reservoir

Air

Purch.

Vendor

Cooling water

Instrument test valves required

Radiographic examination (2.1.2.2)

Continuous flow transfer valves

Separate for coolers and filters

Tight shutoff required

with lifting jack

Rating: psig

Type

Materials: body

Manufacturer

Plug or ball

Model

Trim

319678935.xlsx, 3-27

Page 5 of 8, Date Printed: 05/30/2016

�API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 2 of 4

By:

Date:

Revision:

As built

Supplier

Manufacturer

Purchase Order No.

Date

Inquiry no.

Requisition No.

Oil conditioners: (if required)

Purchasers item no.

Driver for

Type

HP and enclosure

Portable or mounted on

Volts/PH/Hz

Rated GPM of oil

____

____

Manufacturer

Water removal rate

Model

Material of construction

Reservoir (1.4)

____

Pumps and drivers (1.5):

Figures no.

Purchaser item nos.

Include options no.

Full details on data sheet

Electric heater (1.4.7.1)

Pump type and material (1.5.1)

Special heater sizing (1.4.7.1.2)

Supplier standard

Oil level glass (1.4.5.1.4)

ANSI/ASME B73.1 horizontal

Low level alarm (1.4.6.2)

ANSI/ASME B73.2 vertical

2-inch fill opening (1.4.5.1.6)

Rotary positive displacement

Sloped bottom (1.4.4.3)

In-line

Free surfaceft2

Submerged

Working capacity (min/gal)

Steel casing (1.2.14)

Retention capacity (min/gal)

API 610

Rundown capacity

Pump quantity and driver(s)

Normal operating range

Single-shaft driven

Charge capacity

Single-motor driven

Insulation clips (1.4.8)

Motor driven start-up w/shaft drive main (1.5.4.1)

Ladder with handrail (1.4.10.1)

Full-sized motor-driven start-up to double

Handrails on top (1.4.10.2)

Dual motor drive

as auxiliary pump (1.5.4)

Non-skid decking (1.4.10.3)

Dual steam turbine main/motor aux. (1.5.4)

Flanged vent

Pump installation

Flanged drain (1.4.4.4)

Removable strainer (1.5.14)

Extra connection (1.4.9)

Mounting pads (1.5.19.1)

Siphon breaker

Top mounted components permitted

Top mounted components are:

Submerged components and materials

Dimensions of tank L x W x H

319678935.xlsx, 3-28

_____ / _____ / _____

(ft)

Page 6 of 8, Date Printed: 05/30/2016

�API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Job No.:

Item No.:

Page: 3 of 4

By:

Date:

Revision:

As built

Supplier

Manufacturer

Purchase Order No.

Date

Inquiry no.

Filters:

Requisition No.

Lube oil rundown tanks

Purchaser item no.

Required, yes or no (1.9.1)

Duplex (1.7.3)

Per Figure 2A-13a or 2A-13b (1.9.1)

10 Micron filtration level (1.7.2)

Purchaser item no.

Manufacturer

Capacity (mins)

Model

Capacity (gal.)

Design/test (psig)

Code construction/stamp

Material (1.9.1)

Design/test (psig)

Material: case and top

Code construction/stamp for

Cartridges: (1.7.6.3)

2A-13a (1.2.17, 1.9.4)

Thermal relief valves (1.7.3.8)

Nonhydroscopic elements (1.7.6.2)

Furnish

_______

extra sets of cartridges.

Coolers:

Type:

None required (1.6.1)

Per filter (extra over other spares).

Single

Connections only for off-base cooler (1.6.1.3)

Shell and tube

Fin fan

Refer to specification

Supplier std.

Plate frame (1.6.1.3)

Purchaser item no(s)

Duty: (Btu/hr) (KW)

Twin units (1.6.1)

Manufacturer

Details on data sheet

Model

Shell and tube:

Water side for steam heating

Design/test shell side (psig)

Water side corrosion allowance

Design/test tube side (psig)

TEMA class

Code construction/stamp (1.2.17)

Fouling factor water/oil side

Tube water velocity and capacity (fps/gpm)

Tube: L/OD/BWG

Material: shell

Removable bundle (1.6.3.4.1)

Channels and covers

Oil temperature control valve

Tube sheets and tubes

Thermal relief valve (1.6.1.7)

Removable tube bundle

Continuous flow transfer valves (1.8)

Separate for coolers and filters (1.8.1.1)

Rating: _______ psig

Type

Materials: body

Manufacturer

Plug or ball

Model

Trim

Spectacle blinds (1.8.5)

319678935.xlsx, 3-29

Page 3 of 8, Date Printed: 05/30/2016

�API 614Chapter 3 DATA SHEET

GENERAL PURPOSE OIL SYSTEM

U.S. CUSTOMARY UNITS

Applicable to

Proposal

Purchase

Supplier

Purchase Order No.

Job No.:

Item No.:

Page: 4 of 4

By:

Date:

Revision:

As built

Manufacturer

Date

Shop inspection

Inquiry no.

Requisition No.

Shop test

Compliance with inspectors checklist (4.1.1)

Required

Required for system assemblies

Cleanliness

Cleanliness prior to closure

Unit console test (4.3.1.3)

Required for major components

Check controls

Material certifications to be furnished

Changeover filters/coolers

Special examinations

One and two pump operation

Code construction/stamp

Sound level

Certified copies of all test logs and data

Hydro test assembled system

Check pipe strain (4.3.1.4)

Use for complete unit shop test (4.3.1.2)

Pipe radiography (2.1.2.2)

Certified copies of all test logs and data

Witness

Sound level recorded during test

Comments:

319678935.xlsx, 3-30

Page 4 of 8, Date Printed: 05/30/2016