Tribhuvan University

Institute of Engineering

Pulchowk Campus

Department of Mechanical Engineering

ENGINEERING DRAWING II (ME 451)

[Tutorial Sheets]

2073

�ENGINEERING DRAWING II

SHEET NO: 1

(Isometric Drawings)

1. Draw an isometric Drawing of the following orthographic drawing

Figure 1a

Figure 1b

Figure 1c

Figure 1d

�Figure 1e

Figure 1f

Figure 1

�ENGINEERING DRAWING II

SHEET NO: 2

(Pictorial and sectional isometrics)

1. Draw sectional isometric Drawing

22

30

50

70

30

0

2

2 10

Figure 2a

Figure 2b

Figure 2c

Figure 2d

�2. A cylindrical slab having 80 mm as diameter and 50 mm thickness, is surmounted by

a cube of edge 40 mm. On the top of the cube rests a square pyramid of altitude 50

mm and side of base 25 mm. The axes of the solids are in the same straight line. Draw

the isomeric view of the combination of these solids.

3. A hemisphere of diameter 40 mm rests centrally over a frustum of cone of base

diameter 60 mm, top diameter 30 mm and height 60 mm. Draw isometric projections

of the combination of solids.

4. A cylindrical slab of 70 mm as diameter and 40 mm thickness is surmounted by a

frustum of a square pyramid of base side 50 mm, top base side 25 mm and height 40

mm. The axes of the two solids are on a common straight line. A sphere of diameter

40mm is centrally placed on top of the frustum. Draw the isometric view of the solids.

5. A cube of sides 60mm is resting on the ground. A cylinder of base diameter 50 mm

and height 60mm is kept over that. On top of the cylinder, a hexagonal pyramid of

side of base 20 mm and altitude 40 mm is kept. The axis of the three solids lies in the

same vertical line. Draw the isometric view.

6. Draw the isometric projection of a solid rectangular block of size 40X30X50 then

compare with its isometric drawing (view).

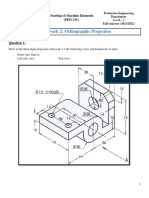

�ENGINEERING DRAWING II

SHEET NO: 3

(Oblique Drawings)

1. Draw the Oblique Drawing of the following orthographic Drawings

Figure 3a

Figure 3b

Figure 3c

Figure 3d

�Figure 3e

Figure 3f

Figure 3g

�30

ENGINEERING DRAWING II

SHEET NO: 4

(Perspectives Drawings I)

1. Draw the Parallel perspective projection from the given orthographic views.

30

45

20

60

Figure 4.1a

Figure 4.1b

15

30

100

10

60

12

50

Figure 4.1c

Figure 4.1d

30

10

�20

40

Draw the angular perspective projection from the given orthographic views.

35

30

80

35

50

45

Figure 4.2b

27

Figure 4.2a

72

30

54

2.

72

Figure 4.2c

Figure 4.2d

�ENGINEERING DRAWING II

SHEET NO: 5

(Perspectives Drawings II)

1. A cube of side base 30 mm rests with it base on the ground and one of the faces

inclined at 450 to the picture plane. The nearest vertical edges touches the PP. The

station point is 50 mm in front of the PP, 60 mm above the ground an opposite to the

nearest vertical edge that touches the PP. Draw the perspective view.

2. A square prism of side base 30 mm and height 50 mm rests with it base on the ground

and one of the rectangular faces inclined at 300 to the picture plane. The nearest

vertical edges touches the PP. The station point is 45 mm in front of the PP, 60 mm

above the ground an opposite to the nearest vertical edge that touches the PP. Draw

the perspective view of the prism.

3. Draw the perspective view of a cube of 25 mm edge, resting on ground with one of its

faces. It has one of its nearest vertical edges is 10 mm behind the picture plane and all

its vertical faces are equally inclined the picture plane. The station point is 55 mm in

front of the picture plane, 40 mm above the ground and lies in the central plane, which

is 10 mm left of the center of the cube.

4. A model of steps has 3 steps of 15 mm tread and rise 10 mm. The steps measure 50

mm wide. The vertical edge of bottom steps, which is nearer to the picture plane, is

25 mm behind PP and the width of steps recede to the left at an angle of 30 0 to PP.

The station point is 100 mm in front of PP and 60 mm above the ground plane and 30

mm to the right of the vertical edge, which is nearest to PP. Draw the perspective view

of the model.

5. A hexagonal prism, side of base 25 mm and height 50 mm with its base on the ground

plane such that one of its rectangular faces is inclined at 30 0 to the picture plane and

the vertical edge nearer to PP is 15 mm behind it. The station point is 45 mm in front

of the picture plane. 70 mm above the ground plane and lies in a central plane, which

is 15 mm left to the vertical edge nearer to the picture plane. Draw the perspective

projection of the prism.

10

�ENGINEERING DRAWING II

SHEET NO: 6

Orthographic Sectional Views

1. Draw full sectional front view.

2. Draw sectional view at A-A.

3. Draw revolved section view at A-A.

4. Draw offset section for A-A in figure.

11

�5. Draw the removed and rotated section at A- A and B-B.

6. Complete the front sectional view including missing lines and intersection curves.

12

�ENGINEERING DRAWING II

SHEET NO: 7

(Limit, fit and Tolerance, Riveting and Nut, bolt, stud,)

1. In freehand sketch, make the complete fit analysis of the following fit symbols.(indicate

the type of fit ,the allowance, upper and lower limit , upper and lower deviation, and

Hole of Shaft basis system)

a. 50H8/d9

b.100 H7/s6 c. 60S6/h12 d. 130 H7/u6 e.150 H7/n6 f. 180 S7/h6

Given Data

Fundamental Deviation (in mm) given by Tolerance position Letter

50 mm

60 mm

100 mm

130 mm

150 mm

180 mm

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

-0.080

-0.100

-0.120

-0.145

0.145

0.145

-0.034

-0.042

-0.058

0.043

0.053

0.071

0.092

0.100

0.108

0.017

0.02

0.02

0.020

0.023

0.023

0.070

0.087

0.124

0.170

0.190

0.210

International tolerance Grade given by the IT Number in mm.

2. Make top view and sectional front view of the following riveted joint

a. Single row lap riveted joint

b. Double row, chain lap riveted joint

c. Double riveted zig-zag lap joint

d. Single row, single strap riveted butt joint

e. Single row, double strap butt riveted joint

g. Double row, double strap chain riveted butt joint

f. Double row, double strap zig-zag, riveted butt joint

3. Make the conventional three views of Hex.M16 X3X40/60

4. Make the conventional three views of stud M 20 20/60

5. Make the conventional three views of SQ bolt of M20

13

�ENGINEERING DRAWING II

SHEET NO: 8

(Graphical Symbols)

1. Sketch freehand the graphical symbols for the following welding items.

2. Sketch free hand the graphical symbols for the following machining and surface roughness

items.

a. Surface may be produced by any method

b. Material removal by machining is required

c. Surface to be obtained without removal of material

d. Surface to be obtained by casting, milling, Nickel plated, precision grinding, fine turning, etc.

e. Surface to be coated.

14

�3. Sketch the roughness grade symbols for the surfaces produced by

4.

Sketch the lay symbols and different surface finish-conditions.

15

�5. Sketch free hand the graphical symbols for the following joints and parts piping items

16

�6. Sketch free hand the graphical symbols for the following engineering items.

A. Electronics and Electrical

17

�18

�B. Structural Items

C. Other Engineering Architecture, Civil, Agriculture, Topographic etc. item

19

�20

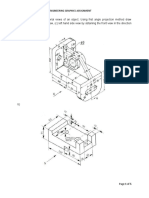

�ENGINEERING DRAWING II

SHEET NO: 9

(Detail Drawings)

1. Draw and dimension the detail drawing of the following items.

21

�22

�ENGINEERING DRAWING II

SHEET NO: 10

(Assembly Drawing I)

Draw and dimension the detail drawing of the following items.

23

�24

�25

�ENGINEERING DRAWING II

SHEET NO: 11

(Assembly Drawing II)

26

�27

�28

�29