Govt.

of India

Ministry of MSME

Project Profile On

LED Based Lighting systems (LED Lamps)

(i)

(ii)

Product Code

ASICC 77489

NIC 2004 31509

Quality standards:

Production Capacity:

Year of Preparation:

As per IS 16102 (Part I &II) 2012

45000 Nos. per annum

2014-2015

Prepared By

MICRO, SMALL & MEDIUM ENTERPRISES DEVELOPMENT

INSTITUTE, PATLIPUTRA INDUSTRIAL ESTATE,

PATNA-800013

�1. INTRODUCTION- LED is semiconductor Technology that emits light at the

junction of oppositely charged materials when voltage forces electron

movement. Led based lighting systems are devices consisting of many LEDs

chips embedded on the LED fixtures base and fitted with rectifier circuit that

provides regulated current output at the low voltage that makes them to be

operated on AC Circuit because LEDs requires DC to operate.

The whole PCB circuit board is fitted inside a plastic enclosure along with the

metallic cap and Smokey reflector.

2. MARKET POTENTIAL- Conventional lighting systems represent mainly

incandescent light bulbs and compact fluorescent lights (CFLs).LED lighting

system provides advantages over conventional lighting systems in terms of

better energy efficiency, better energy costs, longer lifetime, less temp.

Sensivity, higher light output. This leads them to be better Lighting substitute

and good market prospect. Therefore the market prospect for LED based

Lighting system is good and booming.

3. Basis and presumptions

(i)

The basis for calculation of production capacity has been taken on

single shift basis on 75% efficiency.

(ii)

The maximum capacity utilisation on single shift basis for 300 days

a year. During first year and second year of operations the capacity

utilisation is 60% and 80% respectively. The unit is expected to

achieve full capacity utilisation from the third year onward.

(iii) The salaries and wages, cost of raw materials, utilities, rent etc are

based on the prevailing rates in and around Patna. These cost

factors are likely to vary with time and location.

(iv)

Interest on term loan and working capital loan must be preferably

current rate. Otherwise the rate of interest on an average may be

taken as 13%. This rate may vary depending upon the policy of the

financial institution/agencies from time to time.

(v)

The cost of machinery and equipment refer to a particular

make/model and prices are approximate.

(vi)

The breakeven point percentage indicated is of full capacity

utilisation.

(vii) The project preparation cost etc whenever required could be

considered under preoperative expenses.

(viii) The essential production machinery and test equipments required

for the projects have been indicated. The unit may utilize common

test facilitates available at ETDC and ERTLs and Regional Testing

Centre (RTC).

Implementation Schedule

The major activities in the implementation of the project has been listed and the

average time for implementation of the project is estimated at 12 months:

Name of activity

Period in months (suggestive)

1.Preparation of Project Report

1

2.Registration and other formalities

1

�3.Sanction of loan by financial institution

3

4. Plant and machinery

(a) Placement of order

1

(b) Procurement

2

(c) Installation /erection of machinery/test equipments

2

5.Procurement of raw material

2

6.Recruitment of technical person etc

2

7. Trial production

11th month

8.commercial production

12th month

Note

1. Many of the above activities shall be initiated concurrently.

2. Procurement of raw materials commences from 8th month onwards.

3. When imported plant and machinery are required the implementation period of

projects may vary from 12 months to 15 months.

Technical aspect

Process of Manufacturing; This project profile is made for the assembling of LED

based Lighting system cum LED Lamp up to 10 W. The assembling of LED based

Lighting system cum LED Lamp consists of the following steps:

1. Procurement/import of LED chips of Mili Watt rating, Procurement of Circuit

and other mounting devices.

2. Embedding of LED Chips of miliwatt rating on the PCB board with the

rectifier circuit, filter circuit etc.

3. Fitting of PCB Board with the holder cap and plastic modules fitted with the

Smokey reflector to form a compact unit.

4. Testing of the assembled LED Lighting systems and packing

Quality controls & Standards

As Per IS 16102 (Part I & II) 2012

Production Capacity (Per annum)

Qty; 45000Nos.

Value: Rs.6750000

4.

Motive power

5kw

5. Pollution control

The govt. Accords utmost importance to control environmental pollution. The

Small- Scale entrepreneur should have an environmental friendly attitude and

adopt pollution control measures by process modification and technology

substitutions.

India having acceded to the Montreal Protocol in sept.1992,the production and use

of Ozone depleting substances (ODS) like Chlorofluore Carbon (CFCs), carbon

tetrachloride, halons and methyl Chloroform etc. Need to be phased out

immediately with alternative chemicals/solvents. A notification for detailed rules

to regulate ODS phase out under the Environment Protection Act 1986 have been

put in place with effect from 19th July 2000.

The following steps are suggested which may help to control pollution in

electronics industry wherever applicable:

�i) In electronic industry fumes and gases are released during hand

soldering/wave soldering/dip soldering, which are harmful to people as

well as environmental and the end products. Alternative technologies may

be used to phase-out the existing polluting technologies. Numerous new

fluxes have been developed containing 2-10% solids as apposed to the

traditional 15-35 % solids.

ii) Electronic industry uses CFCs,carbon tetrachloride and Methyl chloroform for

cleaning of printed Circiut boards after assembly to remove flux residues

left after soldering and various kinds of foams for packaging.

Many alternative solvents could replace CFC-113 and methyl chloroform in

electronics cleaning. Other chlorinated convents such as trichloroethylene,per

chloroethylene and methylene chloride have been used an effective cleaners in

electronic industry for many years. Other organic solvents such as Ketenes and

Alcolols are effective in removing both solder fluxes and many polar

contaminants.

6.Energy conservation

With the growing energy needs and shortage coupled with rising energy cost, a

greater thrust in energy efficiency in industrial sector has been given by Govt. of

India since 1980s. The energy Conservation Act 2001 has been enacted on 18th

August 2001which provides for efficient use of energy its conservation and

capacity building of Bureau of Energy Efficiency created under the act.

The following steps may be help for conservation of Electrical Energy:

i)

Adoption of energy conserving technology, production aids and testing

facilities.

ii)

Efficient management of process/manufacturing machineries and systems,

QC and testing equipments for yielding maximum energy conservation.

iii)

Optimum use of electrical energy for heating during soldering process can

be obtained by using efficient temperature controlled soldering and

desoldering stations.

iv)

Periodical maintenance of motors compressors etc

v)

Use of power factor correction capacitors, proper selection and layout of

lighting systems timely switching on/off of the lights, use of Compact

Fluorescent Lamps wherever possible.

FINANCIAL ASPECT

(I) Land and building

Built up Area

Office, Store

Assembly and Testing

Rent payable Per Annum

3000 SqFt

1000 Sq Ft

2000 Sq Ft

6000

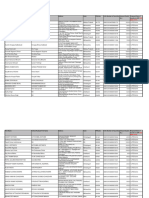

(ii) Machinery and equipment

Sn

1

Description

Component forming

Ind/imp

Indian

Qty

02

Value (RS.)

1,00000

�machine

2

Soldering Machine

Indian

10

5,000

Digital Multimeter

Indian

02

8,000

Continuity Tester

Indian

10

1000

Sealing Machine

Indian

01

10,000

Packaging Machine

Indian

01

15,000

7

8

9

10

11

LCR Meter

Small Drilling M/C Set

Lux Meter

Oscilloscope

Personnel Computer

with UPS and Printer

Miscellaneous items

Indian

Indian

Indian

Indian

Indian

02

01

01

01

01

20,000

10,000

40,000

60,000

80,000

10,000

Total = 359000

Other Fixed Assets in (RS.)

Electrification

charges@10%of cost

of machinery and

equipment

Office equipment,

furniture and working

table etc

Tools, jigs and fixtures

Pre operative expenses

Misc.

Total

35900

20,000

20,000

5,000

5,000

85900

Total Fixed Capital = 444900

Working Capital Per Month

i)

Staff & Labour

SN

Description

No of

Persons

Salary/month

(RS.)

Supervisor Cum Manager

01

8,000

Skilled Worker

05

4,000

Total Salary

per month

(RS.)

8,000

20,000

Accountant

01

6,000

6,000

Total = 34,000

ii)

Raw Material Requirement Per Month

SN

1

Description

LED Chips

Qty

Rate

Value (Rs.)

180000

45000

Rectifier Circuit with

filter

3750

20

75000

Heat Sink Devices

3750

18750

Metallic Cap Holder

3750

10

37500

Plastic Body

3750

10

37500

Reflector Plastic Glass

3750

10

37500

Connecting wire

Lumsum

5,000

Soldering Flux

Lumsum

5,000

10

Miscellaneous

10,000

11

Packaging Material

10,000

Total= 416250

iii)

Utilities Per Month

Value in (RS.)

Power

Water

3,000

500

Total=3500

Other Contingent Expenditure Per Month

SN

1

2

3

4

5

6

7

8

Item

Rent

Postage and stationary

Telephone/fax

Repair & Maintenance

Transport and Conveyance charges

Adv. And publicity

Insurance and Taxes

Miscellaneous expenditure

Amount (RS.)

6000

500

2000

1000

1500

1000

1000

1000

Total= 14000

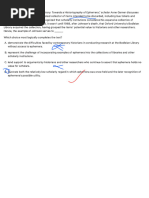

�Total Reoccurring Expenditure Per Month (I+ii+iii+iv)= 467750

Total Capital Investment (In RS.)

Fixed capital

Working capital for three month

444900

1403250

Total= 1848150

Financial analysis

Cost of production per annum

Total reoccurring expenditure

Depreciation on machinery and

equipment@10%

Depreciation on tools, jigs and

fixtures @25%

Depreciation on office equipments,

furniture @ 20%

Interest on total Capital investment

@ 13%

5613000

35900

5000

4000

240259

Total= 5898159

Turn over per annum

Item

Qty (Nos)

Rate/unit

LED Lamp

45000

150

Total value (Rs.)

6750000

Profit per annum (before Taxes)= Turn over per annum- Cost of Production

per annum = 851841

Net profit ratio= profit/annum*100/sales/annum = 13%

Rate of Return = Profit/annum*100/ Total Capital Investment = 46%

Break-even Point

Fixed cost per annum

Rent

Depreciation on machinery and

equipment @ 10%

72000

35900

�Depreciation on tools, jigs and

fixtures @ 25%

Depreciation on office equipment,

furniture @ 20%

Interest on total capital

investment@13%

Insurance

40% of salaries and wages

40% of other contingents & utilities

(excluding rent & insurance)

Total fixed cost

5000

4000

240259

1000

163200

33600

554959

Break even point = fixed cost *100/ fixed cost +Profit

= 554959X100/1406800=39%

Additional information

The Project Profile may be modified/tailored to suit the individual

entrepreneurship qualities/capacity, production programme and also

suit the location characteristics, wherever applicable.

The margin money recommended is 25 % of the working capital

requirement at an average. However, the percentage of margin money

may vary as per banks discretion

Name & address of Machinery and equipment supplier

1. Kamal Electronics, 14, Lakshmi Building, J.C.Road,Bangalore-560002

2. Static systems Pvt. Ltd.,925,II Floor,3rd Main,3rd Cross,D block,2nd

Stage,Rajajinagar,Bangalore-560010

3. Buljin ELMEC Pvt. Ltd.,2/10,Plot No. 65 &78,Krishna Industrial

estate,Mettukuppam,Vanagaram,Chennai-600095

Name & address of raw Material Suppliers

1. M/S Micrologix,473/D,13th Cross,4th Phase,Peenya industrial Area,

Bangalore 560058

2.B.M.V. Circuit Systems,C/321, sector 10,Noida-201301

3.M/S Signal Circuits,7,Navjeevan,Rajguru Nagar,Pune-410505