0% found this document useful (2 votes)

789 views1 pageElectric Actuator Connection Guide

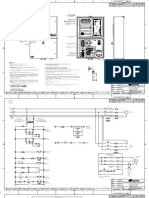

The document describes the main structure and electric connection of an actuator. It lists 16 main components of the actuator structure including a valve motor, spur gear, worm part, and digital sensor. It provides instructions for connecting the actuator electrically, noting to check the power voltage, supply appropriate protection equipment, connect the grounding bolt, and ensure no power before removing covers. Detailed guidelines are given for selecting cable glands and sealing cables according to international standards.

Uploaded by

mersiumCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (2 votes)

789 views1 pageElectric Actuator Connection Guide

The document describes the main structure and electric connection of an actuator. It lists 16 main components of the actuator structure including a valve motor, spur gear, worm part, and digital sensor. It provides instructions for connecting the actuator electrically, noting to check the power voltage, supply appropriate protection equipment, connect the grounding bolt, and ensure no power before removing covers. Detailed guidelines are given for selecting cable glands and sealing cables according to international standards.

Uploaded by

mersiumCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 1

Figure 2 The main structure of the actuator

1. valve motor

6. output shaft

10. flange

14. drive part

2. spur gear

3. worm part

4. handwheel

5. changeover lever

7. main housing 8. crank

9. Torque-dependent mechanism

11. electric control unit 12. operation panel

13. terminal box

15. digital sensor

16. travel axis

3.2 Electric connection

z Check the power voltage according to the nameplate.

z The user should supply the appropriate electric protection equipment such as circuit breaker, air

switch or fuse to protect the actuator.

z There is an M8 grounding bolt on the housing of actuator to connect the outer grounding.

z Making sure that there is no power before removing the terminal cover

z Cable connection.

Select the suitable cable gland according to the international standard or certificated by authority

organization. Especially in the danger zone, the sealing must be accord with the standard. Cable seal

bush, shrink pipe, plug and adapter should be qualified products.

The cable gland should be prepared by the user according the actual cable usually. The Ex. degree

of Ex. cable gland should not below that of actuator.

The thread of cable entry is pg 211, pg161 for non-intrusive 2SA3 series electric actuator.

The cable gland should be adapted to cable entry. The sealing pipe of cable should be screwed (not

less than 5 circles) and sealed with thread sealant in order to insure the waterproof.

If the cable sealing pipe has been removed, the removed parts in the cable entry should be placed

with the original position to avoid losing.

The unused cable entry should be plug up with steeliness thread or coppery faucet. The thread

sealant should be also used for Ex. type actuator.

5