0% found this document useful (0 votes)

368 views2 pagesSetting Part Zero Offset

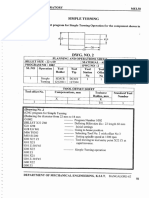

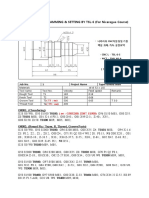

The document describes how to set part zero offset and tool length offset on a milling machine. It involves using a pointer tool to locate the upper left corner of the workpiece to set the part zero offset. It then explains touching off each tool to measure the distance from the tip of the tool to the top of the workpiece to set the tool length offset.

Uploaded by

Eduardo Aleman ReynaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

368 views2 pagesSetting Part Zero Offset

The document describes how to set part zero offset and tool length offset on a milling machine. It involves using a pointer tool to locate the upper left corner of the workpiece to set the part zero offset. It then explains touching off each tool to measure the distance from the tip of the tool to the top of the workpiece to set the tool length offset.

Uploaded by

Eduardo Aleman ReynaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 2