0% found this document useful (0 votes)

650 views13 pagesControl Valve Analysis1

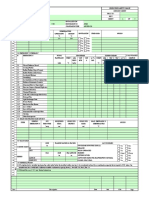

This document describes the steps to size a control valve for liquid flow. It provides data on the liquid properties and flow conditions. It then shows the calculations to determine the valve size coefficient (Cv), select the proper valve type and size, and check that the valve exit velocity is acceptable. A 6-inch globe valve is selected for a flow rate of 432 gpm of Dowtherm Q liquid at a pressure drop of 3.975 psi across the valve.

Uploaded by

Ekundayo JohnCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

650 views13 pagesControl Valve Analysis1

This document describes the steps to size a control valve for liquid flow. It provides data on the liquid properties and flow conditions. It then shows the calculations to determine the valve size coefficient (Cv), select the proper valve type and size, and check that the valve exit velocity is acceptable. A 6-inch globe valve is selected for a flow rate of 432 gpm of Dowtherm Q liquid at a pressure drop of 3.975 psi across the valve.

Uploaded by

Ekundayo JohnCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

/ 13