0% found this document useful (0 votes)

170 views11 pagesSheet Metal Unfolding Techniques

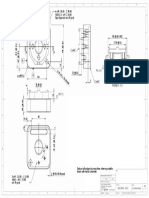

This document presents methods for computing the flat patterns of sheet metal parts made through bending. It describes the unbending method, which uses formulas to compute the unfolded length of bends based on parameters like thickness, radii, and angle. It provides the formulas for different computation types (neutral fiber, internal dimension, etc.) and discusses using correction values from material tables. Samples are given to demonstrate applying these methods to compute the unfolded length of a part.

Uploaded by

Nina GregorioCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

170 views11 pagesSheet Metal Unfolding Techniques

This document presents methods for computing the flat patterns of sheet metal parts made through bending. It describes the unbending method, which uses formulas to compute the unfolded length of bends based on parameters like thickness, radii, and angle. It provides the formulas for different computation types (neutral fiber, internal dimension, etc.) and discusses using correction values from material tables. Samples are given to demonstrate applying these methods to compute the unfolded length of a part.

Uploaded by

Nina GregorioCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 11