0% found this document useful (0 votes)

2K views7 pagesDesign of Coping Beam (Portal) : A. Basic Data

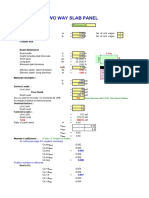

This document provides design details for the reinforcement of a coping beam. It includes calculations for the required reinforcement areas, bar diameters and spacing to resist bending moments, shear forces, and cracking. The design meets requirements for minimum reinforcement, shear capacity, development length and crack control. Stirrups are specified as 16mm diameter bars at 100mm spacing. Top and bottom reinforcement consists of 15 bars of 25mm diameter each.

Uploaded by

Uzziel Abib GabiolaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views7 pagesDesign of Coping Beam (Portal) : A. Basic Data

This document provides design details for the reinforcement of a coping beam. It includes calculations for the required reinforcement areas, bar diameters and spacing to resist bending moments, shear forces, and cracking. The design meets requirements for minimum reinforcement, shear capacity, development length and crack control. Stirrups are specified as 16mm diameter bars at 100mm spacing. Top and bottom reinforcement consists of 15 bars of 25mm diameter each.

Uploaded by

Uzziel Abib GabiolaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 7