0% found this document useful (0 votes)

1K views3 pagesSample Checklist

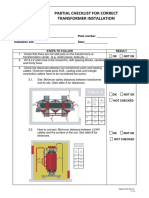

The document provides an inspection checklist form to ensure that all electrical works carried out by contractors are properly implemented according to design drawings. It introduces the need for inspection checklists to determine if works are done according to drawings. Finally, it lists 29 different inspection checklists that can be used as guidance for inspection of various electrical installation works.

Uploaded by

rkssCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views3 pagesSample Checklist

The document provides an inspection checklist form to ensure that all electrical works carried out by contractors are properly implemented according to design drawings. It introduces the need for inspection checklists to determine if works are done according to drawings. Finally, it lists 29 different inspection checklists that can be used as guidance for inspection of various electrical installation works.

Uploaded by

rkssCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 3