0% found this document useful (0 votes)

288 views2 pagesDistortion

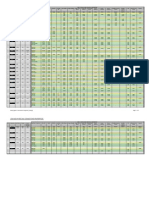

Welding causes distortion of the welded components due to uneven heating and cooling during the process. As the weld cools and shrinks, stresses are exerted on the surrounding metal that can cause plastic deformation and lasting changes in dimensions if the stresses exceed the material's yield strength. Several types of distortion can occur, including longitudinal shrinkage, transverse shrinkage, angular distortion, bowing, buckling, and twisting. The amount of distortion depends on factors like the restraint on the component, welding procedure, parent metal properties, joint design, and how well the parts are fit together before welding.

Uploaded by

mahendraCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

288 views2 pagesDistortion

Welding causes distortion of the welded components due to uneven heating and cooling during the process. As the weld cools and shrinks, stresses are exerted on the surrounding metal that can cause plastic deformation and lasting changes in dimensions if the stresses exceed the material's yield strength. Several types of distortion can occur, including longitudinal shrinkage, transverse shrinkage, angular distortion, bowing, buckling, and twisting. The amount of distortion depends on factors like the restraint on the component, welding procedure, parent metal properties, joint design, and how well the parts are fit together before welding.

Uploaded by

mahendraCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

/ 2