0% found this document useful (0 votes)

604 views1 pageWeld Mesh Panel Report

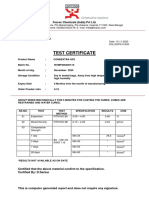

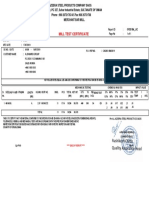

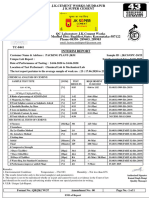

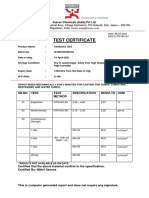

1. A quality test report for 400 welded mesh panels found them to meet all physical test requirements for tensile strength, zinc coating, adhesion, mesh size, weld strength, panel size, and visual inspection.

2. Tests of the raw wire components before fabrication found diameters, tensile strengths, and zinc coatings to be within specified tolerances.

3. All measurements and observations for the welded mesh panels were in compliance with the relevant standards and work order requirements.

Uploaded by

Mahfooz AlamCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

0% found this document useful (0 votes)

604 views1 pageWeld Mesh Panel Report

1. A quality test report for 400 welded mesh panels found them to meet all physical test requirements for tensile strength, zinc coating, adhesion, mesh size, weld strength, panel size, and visual inspection.

2. Tests of the raw wire components before fabrication found diameters, tensile strengths, and zinc coatings to be within specified tolerances.

3. All measurements and observations for the welded mesh panels were in compliance with the relevant standards and work order requirements.

Uploaded by

Mahfooz AlamCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

/ 1