Piles Extension

Uploaded by

mrmerajPiles Extension

Uploaded by

mrmerajNOTE:Refer to AWS D1.

5 for prequalified NOTES

| Steel pipe pile joint designation B-U5a.

PILE SPLICES:Use only E7018 series electrodes. Prepare the weld

surfaces to a smooth, uniform finish. Remove all fins, tears, loose scale,

1 slag, rust, grease, moisture and other material that would prevent proper

0" to 8" root landing

45° welding.

Back

gouge Bevel upper member only PILE TIPS:Use only E7018 series electrodes to attach pile tips.

45°

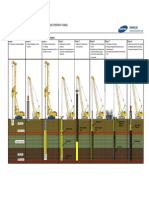

WEB & FLANGE DETAIL PILE TYPE: See Footing Plan sheets for correct pile type, pile tip

and pile tip elevations.

45°

5

(16)

Inside-fit conical driving point

1

0" to 8" root opening

Clean root of weld by grinding

Subsequent passes

CONICAL DRIVING POINT WELD DETAIL or air-arc gouging. Remove to

3

sound metal before welding this side 16" thick (maximum)

Slip driving point inside pipe.

Root pass14" thick (maximum)

PILE EXTENSION AFTER DRIVING

(Pile Vertical)

NOTE:Refer to AWS D1.5 for prequalified

joint designation B-U3b. WEB & FLANGE DETAIL

1

8" thick passes (maximum)

60° 1

0" to 8" root landing

Back

gouge

60°

| Steel pipe pile

1

Root pass 4"thick

(maximum)

1

Clean root of weld by grinding 0" to 8" root opening

or air-arc gouging. Remove to

sound metal before welding this side

5

(16) Open ended inside-fit

cutting shoe PILE EXTENSION BEFORE DRIVING

CUTTING SHOE WELD DETAIL

WELDED SPLICES FOR STEEL HP PILES

Slip shoe inside pipe.

FIRST STEP: SECOND STEP:

Gage of Pile T Weld Size S

| Steel HP pile Burn or cut slits in valleys. Crimp with tool or use sledge.

CE

PS

1

NOTE:Refer to AWS D1.1 for prequalified 0" to 8" root landing 9 gage 1

3" minimum 1" square material 4"

LE SPLI

LE TI

joint designation B-U4a. (0.1495")

PIPE WALL DETAIL 7 gage 5

| Steel pipe pile 6" 16"

(0.1793")

LS AND PI

3-

45°

4

4" 5 gage 5

STANDARD PI

16"

e

(0.2092")

No Scal

Burned end of extension

Bevel top

3 gage 3

member only 8"

(0.2391")

Typ. both Slit every valley

Subsequent passes

H-pile point (16)

5 flanges 1

DETAI

8" thick (maximum)

1

Root pass 8" thick (maximum) THIRD STEP:

H-PILE POINT WELD DETAIL

Do not weld web or inside of flanges. Insert field crimped end into pile

1

3" x 4" backing ring to be extended. Fit snug and weld.

T

45° to fit inside diameter of pipe

PILE EXTENSION AFTER DRIVING FIELD CRIMPING DETAIL FOR CUT-OFF EXTENSIONS

DEPARTMENT

ON

(Pile Vertical)

OF TRANSPORTATI

NOTE:Refer to AWS D1.1 for weld requirements. S

DGE BUREAU

PIPE WALL DETAIL Subsequent passes

Two flutes

MONTANA

1

BRI

8" thick (maximum)

45°

e

| Steel pipe pile

at

LEABBREV$

ckness ofEnd Pl

Root pass 4"

S S

m um )

thick (maximum)

| Steel pipe pile

ni

5"

J.

J.

B.

1"M i

$FI

F.

F.

J.

1

3" x 4" backing ring

D.

D.

T.

Snug fit

(

to fit inside diameter of pipe

Thi

1

0" to 8" root opening Burn four equal spaced

15

15

15

M E$

NOTE:Refer to AWS D1.1 for prequalified notches in lower section

30-

30-

23-

$TI

joint designation B-U2a. before inserting extension

1-

1-

1-

APPROVED

PILE EXTENSION BEFORE DRIVING

CHECKED

5 5

16 (16)

FACTORY CRIMPED EXTENSION FIELD CRIMPED EXTENSION

SED

SED

SED

SED

$DATE$

DRAW N

REVI

REVI

REVI

REVI

WELDED SPLICES FOR STEEL PIPE PILES

WELDED SPLICES FOR STEEL FLUTED PILES

PLATE END WELD DETAIL

DRAWING NO.

Align plate with outside of pipe.

PSD

You might also like

- Base Grouting of Bored Cast-In-Situ Piles at The Railway Bridge Over The River Rupsha, Bangladesh: A Case Study100% (1)Base Grouting of Bored Cast-In-Situ Piles at The Railway Bridge Over The River Rupsha, Bangladesh: A Case Study10 pages

- S-10-1310-020 Specification For PHC Pile - Rev.BNo ratings yetS-10-1310-020 Specification For PHC Pile - Rev.B40 pages

- Behaviour of Single Pile in Sloping Ground Under Static Lateral LoadNo ratings yetBehaviour of Single Pile in Sloping Ground Under Static Lateral Load4 pages

- Pile Testing For Driven or Jack-In Pile PDFNo ratings yetPile Testing For Driven or Jack-In Pile PDF25 pages

- YJMY-BDPLT-A001 - MS02 - Type B - 20180801 - Sample - F PDFNo ratings yetYJMY-BDPLT-A001 - MS02 - Type B - 20180801 - Sample - F PDF40 pages

- 35.pile Foundations in Engineering Practice (S Prakash-H.sharma)No ratings yet35.pile Foundations in Engineering Practice (S Prakash-H.sharma)344 pages

- STEEL SHEET PILE-ESC General Catalogue - CompressedNo ratings yetSTEEL SHEET PILE-ESC General Catalogue - Compressed84 pages

- Undrained Young 'S Modulus of Fine-Grained SoilsNo ratings yetUndrained Young 'S Modulus of Fine-Grained Soils8 pages

- Dynamic Testing Methods of Deep FoundationsNo ratings yetDynamic Testing Methods of Deep Foundations52 pages

- Specification For Contiguous Bored Piling: 1.0 General 1.1 Works in Accordance With SpecificationsNo ratings yetSpecification For Contiguous Bored Piling: 1.0 General 1.1 Works in Accordance With Specifications15 pages

- Soil Improvement Layer (A Simple Approach) by Structural Engineer AyyappadhasNo ratings yetSoil Improvement Layer (A Simple Approach) by Structural Engineer Ayyappadhas3 pages

- New Approach For Tremie Concrete Used For Deep FoundationsNo ratings yetNew Approach For Tremie Concrete Used For Deep Foundations6 pages

- Point Load Test on Meta-Sedimentary RocksNo ratings yetPoint Load Test on Meta-Sedimentary Rocks8 pages

- Yjack - Ms 20170211 - BD For Bp600mm Wl2827kn Tl5654kn100% (1)Yjack - Ms 20170211 - BD For Bp600mm Wl2827kn Tl5654kn56 pages

- Civil: Anchor Bolt Design Per ACI 318-11 Crane Beam DesignNo ratings yetCivil: Anchor Bolt Design Per ACI 318-11 Crane Beam Design8 pages

- Design Construction and Performance of Open Cell Sheet Pile Bridge AbutmentsNo ratings yetDesign Construction and Performance of Open Cell Sheet Pile Bridge Abutments12 pages

- ECB - 2017 - 4 - ECB 2017-4 Interim Poly Vinyl Chloride Sheet Pile Guidance) - EnglishNo ratings yetECB - 2017 - 4 - ECB 2017-4 Interim Poly Vinyl Chloride Sheet Pile Guidance) - English8 pages

- Lindquist Secant Pile Shoring Developments in Design and Construction DFI2011No ratings yetLindquist Secant Pile Shoring Developments in Design and Construction DFI20118 pages

- DFI 47 Maryland Design and Field Comparison of Ground Improvement and Bored Piles For Large Diameter Steel Water TanksNo ratings yetDFI 47 Maryland Design and Field Comparison of Ground Improvement and Bored Piles For Large Diameter Steel Water Tanks10 pages

- Prestressed Concrete Posts 1800 High Prestressed Concrete PostsNo ratings yetPrestressed Concrete Posts 1800 High Prestressed Concrete Posts43 pages

- Piling Design and Construction in Hong KongNo ratings yetPiling Design and Construction in Hong Kong41 pages

- © Pipefitters Union, St. Louis, MO © Pipefitters Union, St. Louis, MONo ratings yet© Pipefitters Union, St. Louis, MO © Pipefitters Union, St. Louis, MO8 pages

- Welding Procedure Specification Register (Structural Steel) : AWS D1.1100% (5)Welding Procedure Specification Register (Structural Steel) : AWS D1.114 pages

- R. Stroetmann, T. Kästner: A New Design Model For Welded JointsNo ratings yetR. Stroetmann, T. Kästner: A New Design Model For Welded Joints1 page

- 1 Clarification of Bolt Tensioning: SteelworkNo ratings yet1 Clarification of Bolt Tensioning: Steelwork1 page

- 8.1 Acceptance Criteria For Bolt Tensioning - Load Indicating WashersNo ratings yet8.1 Acceptance Criteria For Bolt Tensioning - Load Indicating Washers1 page

- Design Bearing Strength (LRFD J3.10) : WhereNo ratings yetDesign Bearing Strength (LRFD J3.10) : Where1 page

- Stairs, Ladders, and Open-Edge Guards For Use With Material Handling Structures100% (1)Stairs, Ladders, and Open-Edge Guards For Use With Material Handling Structures20 pages

- CASTING DEFECTS AND REMEDIAL MEASURES (Final)100% (1)CASTING DEFECTS AND REMEDIAL MEASURES (Final)51 pages

- Filtration: Hydraulic Filters - Section 11ANo ratings yetFiltration: Hydraulic Filters - Section 11A24 pages

- Selection of Welding Process For Hardfacing in Carbon SteelNo ratings yetSelection of Welding Process For Hardfacing in Carbon Steel11 pages

- Metalshield Quick Drying Metal Primer 510: Issued November 2010No ratings yetMetalshield Quick Drying Metal Primer 510: Issued November 20102 pages

- Painting Inspectors (Metal Substrates) : Standard Guide ForNo ratings yetPainting Inspectors (Metal Substrates) : Standard Guide For14 pages