Potential Failure Mode and Effects Analysis (Process FEMA)

Uploaded by

Asif IqbalPotential Failure Mode and Effects Analysis (Process FEMA)

Uploaded by

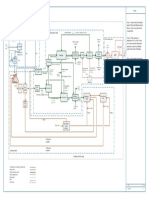

Asif IqbalPOTENTIAL FMEA #:

FAILURE MODE AND EFFECTS ANALYSIS Reference Specs:

(PROCESS FMEA)

Item/Component: Process Responsibility: Prepared by:

Model: Part Number: Date (Orig.)

CoreTeam: Date (last revised)

Approved by:

The Sev and RPN columns auto-calculate.

DETECT

OCCUR

Action Results

CLASS

RPN

SEV

Process Function/ Potential Effect(s) of Potential Cause(s)/ Current Process Controls Current Process Controls Responsibility & Target

# Potential Failure Mode Recommended Actions S O D R.

Requirements Failure Mechanism(s) of Failure Prevention Detection Completion Date

Actions Taken e c e P.

v c t N.

Nut not properly tighten 3 1 1 3 3 0

Missing rubber isoletor 3 1 1 3 3 0

rubber collar not outside the

compressor base plate

3 1 1 3 3 0

Base plate with Thread problem 1 1 1 1 1 0

1

compressor assembly

base plate not proper paint 1 1 1 1 1 0

grounding wire not use in

compressor

2 1 1 2 2 0

Stud missalign 1 1 1 1 1 0

not properly tighten screws 3 3 2 18 3 0

capillary chip & crack 3 1 1 3 3 0

Service valve and capillary Lnkey nut thread slip

2 5 2 1 10 5 0

fix on valve plate

lock of valve plate fixing miss 1 1 1 1 1 0

copper tube damages 4 1 1 4 4 0

condenser fins broken & damage 2 2 1 4 2 0

copper tubes damage & chip 3 2 1 6 3 0

Condenser fix on base

3 ubend leakage & chip 3 1 1 3 3 0

plate

Condenser fixing hole block &

miss

1 1 1 1 1 0

not properly tighten screws 2 1 1 2 2 0

4-way valve & solenoid coil are

not same brand

2 1 1 2 2 0

tubes damage & chip 3 2 1 6 3 0

4-way valve damage 2 1 1 2 2 0

4-way valve fixing &

4

copper tubes fitment all tubes & capillary fixing not

2 1 1 2 2 0

properly

all tubes & capillary missalign 1 1 1 1 1 0

Solenoid coil screw loose 1 1 1 1 1 0

not proper welding 3 1 1 3 3 0

nitrogen pressure not inside the

5 Welding copper tube

1 1 1 1 1 0

leakage problem 2 1 1 2 2 0

motor nut not properly tighten 2 1 1 2 2 0

bracket screws not properly

tighten

2 1 1 2 2 0

Pre-assemble motor fixing

6 & motor bracket fixing on motor wire clip damage 2 1 1 2 2 0

base plate

bracket clip of wire fixing not use 1 1 1 1 1 0

motor body damage 1 1 1 1 1 0

wiring not properly against

wiring diagram

3 1 1 3 3 0

wire damage 1 1 1 1 1 0

Compressor wiring & gasket miss of terminal cover 2 1 1 2 2 0

7

blanket fixing

terminal cover nut not properly

tighten

2 1 1 2 2 0

blanket not proper rapping on

compressor

1 1 1 1 1 0

Partation plate screws not

properly tighten

2 1 1 2 2 0

Spoung miss 1 1 1 1 1 0

partation plate fix on base grove 1 1 1 1 1 0

fixing partation plate &

8

PFC / Capacitor PFC/Capacitor fixing screws not

properly tighten

2 1 1 2 2 0

PFC damage 2 1 1 2 2 0

Service and art pipe coupler not

proper fix 1 1 1 1 1 0

not proper vacuuming 3 1 1 3 3 0

Coupler not proper fix 1 1 1 1 1 0

wiring not properly against

wiring diagram

3 1 1 3 3 0

wire clip damage 1 1 1 1 1 0

PCB damage 2 1 1 2 2 0

Vacuuming, wiring &

9 PCB cover not properly fix 1 1 1 1 1 0

axial fan fixing

all sensor not properly fix 1 1 1 1 1 0

all wires not properly tie 1 1 1 1 1 0

PCB parts damage 2 1 1 2 2 0

axial fan damage 1 1 1 1 1 0

axial fan fixing nut not properly

tighten

2 1 1 2 2 0

dumper not proper paste on

capillary tube

1 1 0 0 1 0

refrigerant not proper fill against

gas weight sheet

3 1 1 3 3 0

The machine charged the leak

unit

3 1 1 3 3 0

Refrigerant filling &

10

Pinch off Gas weight not verification 2 1 0 0 2 0

Pinch pillar not proper pinch 2 1 1 2 2 0

Gas leakage 2 1 1 2 2 0

Welding not properly pinch off 1 1 0 0 1 0

machine working not properly 3 2 1 6 3 0

machine not calibrate 2 1 1 2 2 0

Leak check with Inficon

11

machine Untrained inspector work in leak

check station

2 1 0 0 2 0

Inspector check unit very fast 2 1 0 0 2 0

not properly tighten screws 2 1 1 2 2 0

PCB box damage 1 1 0 0 1 0

Right side plate, PCB box, not proper screw use in 1 1 0 0 1 0

12 Ground wire & Front panel grounding wire

fixing

Electric terminal broken 1 1 0 0 1 0

ground wire screw not properly

tighten

2 1 1 2 2 0

Earth wire not proper work 5 2 1 10 5 0

Insulation resistance test not ok 5 2 1 10 5 0

13 Electrical safety test

wiring problem 3 1 1 3 3 0

Electrical Safety test not ok 5 2 1 10 5 0

testing panel not check before

unit testing

3 1 1 3 3 0

Heating process not check 3 1 1 3 3 0

Current (A) not proper check

against given supplier 3 1 1 3 3 0

specification sheet

Online testing

14 Running pressure not proper

(Performance test) check against given supplier 2 1 1 2 2 0

specification sheet

Inverter PCB not check properly

with supplier device

4 1 1 4 4 0

Power not proper check against

given suppler specification sheet

2 1 1 2 2 0

valve cap not fix & miss 1 1 1 1 1 0

Remove coupler, fix valve diagram sticker miss 2 1 1 2 2 0

cap, diagram paste on

right side handle, rating rating label sticker miss 1 1 1 1 1 0

15 label paste on right side

plate, right side handle fix water collector broken 1 1 1 1 1 0

on eclectic plate & water

collector fixing right side handle broken 1 1 1 1 1 0

Power cable fixing clip miss 1 1 1 1 1 0

not proper cleaning 1 1 1 1 1 0

Cleaning, Packing

installation kit miss 2 1 1 2 2 0

(Polythen bag, installation

17

kit, hole cover & pvc roll polythen bag miss 1 1 1 1 1 0

tape

hole cover & pvc tape miss 1 1 1 1 1 0

carton damage & broken 1 1 1 1 1 0

Packing carton

18 & EPS top miss 1 1 1 1 1 0

Packing strip

packing strip loose 1 1 1 1 1 0

Carton reopen not properly 1 1 1 1 1 0

Dismantling & unit reopen not properly 1 1 1 1 1 0

1

Parts segregation

unit damage to the dismantling

process

2 1 1 2 2 0

3 1 1 3 3 0

not properly screw tighten

2 1 1 2 2 0

cross flow fan broken

Cross flow fan & indoor 2 1 1 2 2 0

2

motor assemble motor shaft tapper

2 1 1 2 2 0

motor wire damage

2 1 1 2 2 0

bearing base not proper place

evaporator fins damage 2 2 1 4 2 0

copper tubes damage & chip 2 1 1 2 2 0

ubend damage & chip 2 1 1 2 2 0

heat exchanger pipe damage &

chip 2 1 1 2 2 0

3 Evaporator fixing

not properly screws tighten 2 2 1 4 2 0

motor cover not proper fix 2 1 1 2 2 0

cover screw not properly tighten 2 1 1 2 2 0

evaporator not properly fix 2 1 1 2 2 0

not properly screw tighten 2 1 1 2 2 0

PCB box damage 1 1 1 1 1 0

PCB with box & ground

4

wire fixing PCB component damage 3 2 1 6 3 0

ground wire not properly screw

tighten

2 1 1 2 2 0

Power cord wire not properly

tighten

2 1 1 2 2 0

terminal broken 2 1 1 2 2 0

Indoor motor wire jack not fix in

the PCB

2 1 1 2 2 0

5 Wiring swing motor wire jack not fix the

PCB

2 1 1 2 2 0

Air & Coil sensor wire jack not fix

the PCB

2 1 1 2 2 0

Coil sensor not fix in evaporator

coil

2 1 1 2 2 0

Enclosure not properly fix 2 1 1 2 2 0

top panel not properly fix 1 1 1 1 1 0

Enclosure & Top panel,

6 filter miss 2 1 1 2 2 0

Filter & Louver flap

not properly screw tighten 2 1 1 2 2 0

louver flap miss & broken 2 1 1 2 2 0

Remote function not check

properly

4 2 1 8 4 0

Inverter PCB not check properly

Online Indoor Testing with supplier device

4 2 1 8 4 0

7

(Performance Test)

louver moment not check 2 1 1 2 2 0

unit vibration not properly check 2 1 1 2 2 0

Hanging plate miss 3 1 1 3 3 0

wrong hanging plate dispatch 2 1 1 2 2 0

Hanging plate &

8 hanging plate damage 2 1 1 2 2 0

Terminal cover

terminal cover not fix 1 1 1 1 1 0

terminal cover broken 1 1 1 1 1 0

not proper cleaning 1 1 1 1 1 0

Cleaning & Packing Power cable miss 1 1 1 1 1 0

9 (Polythen bag & Power

Cable) polythen bag miss 1 1 1 1 1 0

Scratches 1 1 1 1 1 0

Packing carton carton damage & broken 1 1 1 1 1 0

10 &

Packing strip packing strip loose 1 1 1 1 1 0

BE-PDP-FR-07 / Rev D (14-Nov-13) Johnson Controls, Inc. Page 1 of 1

Confidential and Proprietary

You might also like

- Process Failure Modes and Effects Analysis Process Failure Modes and Effects AnalysisNo ratings yetProcess Failure Modes and Effects Analysis Process Failure Modes and Effects Analysis2 pages

- Fmea (Failure Modes and Effects Analysis)No ratings yetFmea (Failure Modes and Effects Analysis)11 pages

- ةراادلا كوبت ءابرهك ةراادإ هرئاادلا ةنايصلاو تايلمعلا مسقلا هكبشلا ةنايص Risk And List Of Ppes Distribution By Function / /: خيراتلا 201No ratings yetةراادلا كوبت ءابرهك ةراادإ هرئاادلا ةنايصلاو تايلمعلا مسقلا هكبشلا ةنايص Risk And List Of Ppes Distribution By Function / /: خيراتلا 20125 pages

- Process FMEA (Failure Mode and Effects Analysis)No ratings yetProcess FMEA (Failure Mode and Effects Analysis)2 pages

- Study of Failure Mode and Effect Analysis (FMEA) On Capacitor Bank Used in Distribution Power SystemsNo ratings yetStudy of Failure Mode and Effect Analysis (FMEA) On Capacitor Bank Used in Distribution Power Systems7 pages

- 10% To 30% Error - May Be Acceptable Based Upon Importance of ApplicationNo ratings yet10% To 30% Error - May Be Acceptable Based Upon Importance of Application3 pages

- OP-7.3.1.1 Process Failure Mode and Effect AnalysisNo ratings yetOP-7.3.1.1 Process Failure Mode and Effect Analysis7 pages

- PNGRB - Electrical Safety Audit ChecklistNo ratings yetPNGRB - Electrical Safety Audit Checklist4 pages

- IEC 60601-1 Update for Compliance ExpertsNo ratings yetIEC 60601-1 Update for Compliance Experts44 pages

- FMEA for Quality Improvement in Auto SMEsNo ratings yetFMEA for Quality Improvement in Auto SMEs17 pages

- Updates On ISO TS 24971 and Formal Objection of The European Commission To INo ratings yetUpdates On ISO TS 24971 and Formal Objection of The European Commission To I6 pages

- Internal and External Issues For Climate ChangeNo ratings yetInternal and External Issues For Climate Change1 page

- Potential Failure Mode and Effects Analysis (Design)No ratings yetPotential Failure Mode and Effects Analysis (Design)12 pages

- JCI Framework For RCA and Corrective Action PlanNo ratings yetJCI Framework For RCA and Corrective Action Plan18 pages

- R0 Workstation and Non-Routine Work Risk Assessment Tool Rev SeptianNo ratings yetR0 Workstation and Non-Routine Work Risk Assessment Tool Rev Septian14 pages

- Failure Mode and Effects Analysis (Design) : Importance in NPD ProcessNo ratings yetFailure Mode and Effects Analysis (Design) : Importance in NPD Process12 pages

- Quality Analysis Using Fmea Method On Assembly Processes of Washing Machine (Case Study in Panasonic Manufacturing Indonesia)No ratings yetQuality Analysis Using Fmea Method On Assembly Processes of Washing Machine (Case Study in Panasonic Manufacturing Indonesia)5 pages

- Personal Protective Equipment: Retention CodeNo ratings yetPersonal Protective Equipment: Retention Code12 pages

- Potential Failure Mode and Effects Analysis: 4 EditionNo ratings yetPotential Failure Mode and Effects Analysis: 4 Edition89 pages

- Hazards Identification of Eot Cranes and Their Control MeasuresNo ratings yetHazards Identification of Eot Cranes and Their Control Measures8 pages

- Standard Operating Procedure: A Process Failure Mode Effects Analysis (PFMEA)50% (2)Standard Operating Procedure: A Process Failure Mode Effects Analysis (PFMEA)2 pages

- Energyscapes, Architecture, and The Expanded Field of Postindustrial PhilosophyNo ratings yetEnergyscapes, Architecture, and The Expanded Field of Postindustrial Philosophy14 pages

- Fundamental Formula of Physics Periodic MotionNo ratings yetFundamental Formula of Physics Periodic Motion3 pages

- Lesson 4.10 Installed Ballasting SystemsNo ratings yetLesson 4.10 Installed Ballasting Systems34 pages

- Executive Summary Automotive Industry Insights Spring 2024No ratings yetExecutive Summary Automotive Industry Insights Spring 202420 pages

- Technical Manual For Air-Cooled Modular Chiller - (FCH01-2020,21E)No ratings yetTechnical Manual For Air-Cooled Modular Chiller - (FCH01-2020,21E)34 pages

- Nonlinear Predictive Control of A Benchmark CSTRNo ratings yetNonlinear Predictive Control of A Benchmark CSTR7 pages

- Performance Task in General Physics Ii (Home Energy Audit) : Saint James AcademyNo ratings yetPerformance Task in General Physics Ii (Home Energy Audit) : Saint James Academy15 pages

- Combination of Capacitor and DielectricNo ratings yetCombination of Capacitor and Dielectric18 pages

- GU - BE - Minor and Honours Degree Programme v1.1No ratings yetGU - BE - Minor and Honours Degree Programme v1.1117 pages

- Copper Heap Leach Plant Process OverviewNo ratings yetCopper Heap Leach Plant Process Overview1 page

- 12 Class Physics Investigatory Project On TransformersdocxNo ratings yet12 Class Physics Investigatory Project On Transformersdocx12 pages

- Statistical and Low Temperature PhysicsNo ratings yetStatistical and Low Temperature Physics76 pages

- A Review On Technology, Configurations, and Performance of Cross Flow Hydrokinetic TurbinesNo ratings yetA Review On Technology, Configurations, and Performance of Cross Flow Hydrokinetic Turbines41 pages

- Ielts General Training Volume 1 Listening Practice Test 3 v9 1309No ratings yetIelts General Training Volume 1 Listening Practice Test 3 v9 130922 pages