0% found this document useful (0 votes)

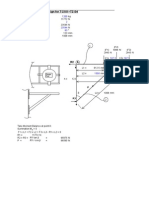

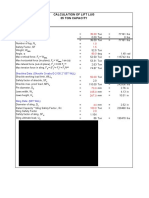

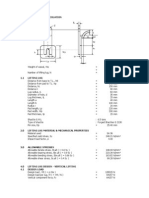

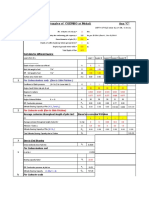

227 views10 pagesLifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton Weight

This document provides calculations for lifting a 110 ton pipe structure using 4 lifting points. It calculates the forces and bending moments at each point. Point 1-2 is determined to be safe, while point 3-4 fails the bending stress calculation in the z-z direction at 251.9% of the allowable stress. Point 3-4 also has safe stresses in the y-y and x-x directions. The document was prepared by an engineer at PT Profab Indonesia to analyze the lifting arrangement.

Uploaded by

rustamriyadiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

227 views10 pagesLifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton Weight

This document provides calculations for lifting a 110 ton pipe structure using 4 lifting points. It calculates the forces and bending moments at each point. Point 1-2 is determined to be safe, while point 3-4 fails the bending stress calculation in the z-z direction at 251.9% of the allowable stress. Point 3-4 also has safe stresses in the y-y and x-x directions. The document was prepared by an engineer at PT Profab Indonesia to analyze the lifting arrangement.

Uploaded by

rustamriyadiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

/ 10