0% found this document useful (0 votes)

449 views1 pageWelding Guide for Oil & Gas Industry

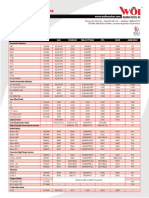

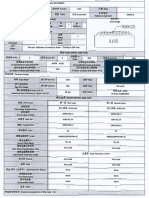

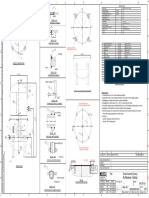

This document outlines welding guidelines for the chemical, oil, and gas industries. It covers topics such as acceptable welding processes, welding consumables, preheating and interpass temperature requirements, post-weld heat treatment, and special procedure qualification requirements including tube-to-tubesheet welding. The document provides requirements and recommendations for ensuring safe and effective welding of materials used in the chemical, oil, and gas industries.

Uploaded by

bacabacabacaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

449 views1 pageWelding Guide for Oil & Gas Industry

This document outlines welding guidelines for the chemical, oil, and gas industries. It covers topics such as acceptable welding processes, welding consumables, preheating and interpass temperature requirements, post-weld heat treatment, and special procedure qualification requirements including tube-to-tubesheet welding. The document provides requirements and recommendations for ensuring safe and effective welding of materials used in the chemical, oil, and gas industries.

Uploaded by

bacabacabacaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 1