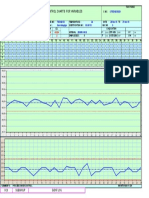

RBD Machine capability study for Milling surface finish with decided Attribute method np CHART

ENGINEERS, Part Number : C001-L1764 Sample Size : 125 Operation : Milling Operator : Atul

AHMEDABAD Parameter : Surface finish on Lug Frequency : Continue Machine Name / No. : 4 Date / Shift : 31.01.2014

Calculations :

1.00

Calculated Control Limits :

0.90

np1 + np2 + …..+ npk

np =

0.80

k

0.70 np = 0

0.60

0.50 UCL =

0.40 UCL = 0

0.30

LCL =

0.20

0.10 LCL = 0

0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

0.00

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Remarks :

Sample (n) 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 Process parameter Set:

Discrepancies

Number

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Speed: 137 RPM

(np, c)

Reason

Feed: 31.5 mm/min

Code

Date 31.01.2014

Conclusion: Process parameter valided.

Time Continuous

REASON CODE :

Note : Any change in people, material, equipment, method, environment or measurement 1 Resetting 5 Maintenance

systems should be noted. These notes will help you to take corrective or process 2 Operator Change 6 Break Down Prepared By: Approved By:

improvement action when signaled by the control chart. 3 Tool Change 7 Change of Material Sumit Milesh

4 Lunch Break 8

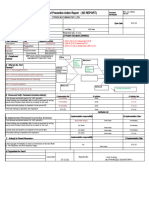

� RBD Control Chart For Attribute Data np CHART

ENGINEERS, Part Number : C001-L1764 Sample Size : 125 Operation : Milling Operator : Atul

AHMEDABAD Parameter : Surface finish on Lug Frequency : Continue Machine Name / No. : 4 Date / Shift : 29.01.2014

Calculations :

6.00

Calculated Control Limits :

5.00 np1 + np2 + …..+ npk

np =

k

4.00

np = 0.8

3.00

2.00 UCL =

1.000.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 UCL = 3.25927

0.00

LCL =

-1.00 LCL = -1.65927

-2.00

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Remarks :

Sample (n) 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 Process parameter Set:

Number

Discrepancies

0 0 0 5 0 0 0 0 3 0 0 0 0 0 0 5 0 0 0 0 0 2 5 0 0 Speed: 270 RPM

(np, c)

Reason

3 1 1 1 Feed: 78 mm/min

Code

Date 29.01.2014

Conclusion: Invalid Process parameter.

Time Continuous

REASON CODE :

Note : Any change in people, material, equipment, method, environment or measurement 1 Resetting 5 Maintenance

systems should be noted. These notes will help you to take corrective or process 2 Operator Change 6 Break Down Prepared By: Approved By:

improvement action when signaled by the control chart. 3 Tool Change 7 Change of Material Sumit Milesh

4 Lunch Break 8

� RBD Control Chart For Attribute Data np CHART

ENGINEERS, Part Number : C001-L1764 Sample Size : 5 Operation : Milling Operator : Atul

AHMEDABAD Parameter : Surface finish on Lug Frequency : Continue Machine Name / No. : 4 Date / Shift : 29.01.2014

Calculations :

6.00

Calculated Control Limits :

5.00 np1 + np2 + …..+ npk

np =

k

4.00

np = 0.56

3.00

2.00 UCL =

1.00 UCL = 2.67554

0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56 0.56

0.00

LCL =

-1.00 LCL = -1.55554

-2.00

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Remarks :

Sample (n) 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 Process parameter Set:

Discrepancies

Number

0 0 0 0 0 0 0 0 2 5 0 0 0 0 0 0 0 0 0 0 0 2 5 0 0 Speed: 190 RPM

(np, c)

Reason

3 1 Feed: 50 mm/min

Code

Date 29.01.2014

Conclusion: Invalid Process parameter.

Time Continuous

REASON CODE :

Note : Any change in people, material, equipment, method, environment or measurement 1 Resetting 5 Maintenance

systems should be noted. These notes will help you to take corrective or process 2 Operator Change 6 Break Down Prepared By: Approved By:

improvement action when signaled by the control chart. 3 Tool Change 7 Change of Material Sumit Milesh

4 Lunch Break 8