0% found this document useful (0 votes)

851 views7 pagesStages of Downstream Processing

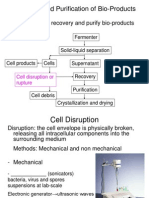

The document discusses downstream processing in fermentation technology. Downstream processing refers to the recovery and purification of fermentation products after production. It involves multiple stages including removal of insoluble materials, product isolation, purification, and polishing. Some key techniques used are centrifugation, filtration, precipitation, chromatography, and drying. The goal is to recover the product in high yields and purity at low cost. Choosing appropriate recovery methods requires considering factors like product properties, costs, scale of production, and quality standards.

Uploaded by

Nitin KhodifadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

851 views7 pagesStages of Downstream Processing

The document discusses downstream processing in fermentation technology. Downstream processing refers to the recovery and purification of fermentation products after production. It involves multiple stages including removal of insoluble materials, product isolation, purification, and polishing. Some key techniques used are centrifugation, filtration, precipitation, chromatography, and drying. The goal is to recover the product in high yields and purity at low cost. Choosing appropriate recovery methods requires considering factors like product properties, costs, scale of production, and quality standards.

Uploaded by

Nitin KhodifadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 7