0% found this document useful (0 votes)

106 views3 pagesMoment Connection Design Specs

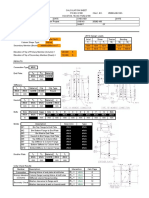

This document summarizes the design of a moment connection using an extended end plate. Key details include:

- The plate, bolts, and member materials and dimensions

- The calculated plastic moment capacity of the section is 65.36 tonne-meters

- The maximum moment from the structure is 13.5 tonne-meters

- Bolt arrangement and calculations to check bolt capacity in tension and shear

- Plate thickness requirements are met with the 20mm provided plate

- Weld sizes provided for the flange and web connections are sufficient

Uploaded by

jatin kalraCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

106 views3 pagesMoment Connection Design Specs

This document summarizes the design of a moment connection using an extended end plate. Key details include:

- The plate, bolts, and member materials and dimensions

- The calculated plastic moment capacity of the section is 65.36 tonne-meters

- The maximum moment from the structure is 13.5 tonne-meters

- Bolt arrangement and calculations to check bolt capacity in tension and shear

- Plate thickness requirements are met with the 20mm provided plate

- Weld sizes provided for the flange and web connections are sufficient

Uploaded by

jatin kalraCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 3