100% found this document useful (1 vote)

234 views9 pagesMethod Statement of Casing Frame

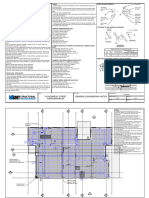

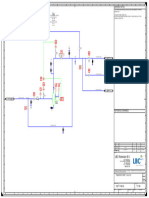

This document provides the method statement for erecting the casing frame in ESP units 1 and 2 of the Jawaharpur Thermal Power Project. It outlines the scope of work, equipment used, staffing plan, material transportation process, rigging plan, lifting procedure, safety measures, inspection checklist, risk analysis, and emergency action plan for the safe erection of the casing frame. The lifting procedure involves using a 250MT crawler crane for lifting and a 75MT crawler crane for tailing the 16.5MT casing frame assembly into its final erected position.

Uploaded by

Kuber Jawaharpur EHSCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

234 views9 pagesMethod Statement of Casing Frame

This document provides the method statement for erecting the casing frame in ESP units 1 and 2 of the Jawaharpur Thermal Power Project. It outlines the scope of work, equipment used, staffing plan, material transportation process, rigging plan, lifting procedure, safety measures, inspection checklist, risk analysis, and emergency action plan for the safe erection of the casing frame. The lifting procedure involves using a 250MT crawler crane for lifting and a 75MT crawler crane for tailing the 16.5MT casing frame assembly into its final erected position.

Uploaded by

Kuber Jawaharpur EHSCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

/ 9