0% found this document useful (0 votes)

204 views22 pagesSpeed Control of Induction Motors - 2 PDF

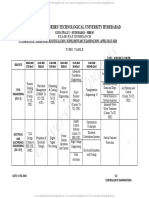

The document discusses various methods for speed control of induction motors, including static frequency changers, static voltage controllers, and rectifier-inverter systems with both line and self-commutation. It also covers closed-loop control techniques such as stator voltage control, volt-hertz control, and slip regulation control. The goal of closed-loop control is to satisfy steady-state and transient performance specifications for variable speed AC drives.

Uploaded by

Zariz ZakianCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

204 views22 pagesSpeed Control of Induction Motors - 2 PDF

The document discusses various methods for speed control of induction motors, including static frequency changers, static voltage controllers, and rectifier-inverter systems with both line and self-commutation. It also covers closed-loop control techniques such as stator voltage control, volt-hertz control, and slip regulation control. The goal of closed-loop control is to satisfy steady-state and transient performance specifications for variable speed AC drives.

Uploaded by

Zariz ZakianCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 22