0% found this document useful (0 votes)

1K views4 pagesRICO 8d Format

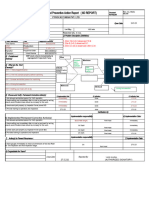

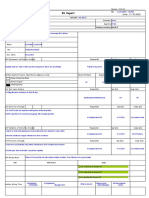

The supplier 8D report summarizes a quality issue with unpainted areas found on a Toyota bracket part supplied by Kamal CED Coating. An investigation was conducted and the root cause was found to be that the hanger patti angle was shifted, causing a lux level issue. Corrective actions taken included replacing the new patti to fix the process root cause. Preventative actions such as revising inspection frequency and control plans were also implemented to monitor for future issues.

Uploaded by

Dinesh KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views4 pagesRICO 8d Format

The supplier 8D report summarizes a quality issue with unpainted areas found on a Toyota bracket part supplied by Kamal CED Coating. An investigation was conducted and the root cause was found to be that the hanger patti angle was shifted, causing a lux level issue. Corrective actions taken included replacing the new patti to fix the process root cause. Preventative actions such as revising inspection frequency and control plans were also implemented to monitor for future issues.

Uploaded by

Dinesh KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

/ 4