0% found this document useful (0 votes)

60 views11 pagesMaterials and Manufacturing: Instructor: Dr. Hamid Jabbar

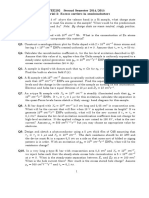

This document contains questions, problems, and lecture materials about materials science and manufacturing from a class called MTS 226. It includes questions about stress and fracture mechanics involving cracks, as well as extrapolation methods for creep data using the Larson-Miller parameter. The questions calculate values like maximum stress, stress ratio, stress range, and allowable stress levels for specific materials at given temperatures and lifetimes.

Uploaded by

ARSLAN FALAKCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

60 views11 pagesMaterials and Manufacturing: Instructor: Dr. Hamid Jabbar

This document contains questions, problems, and lecture materials about materials science and manufacturing from a class called MTS 226. It includes questions about stress and fracture mechanics involving cracks, as well as extrapolation methods for creep data using the Larson-Miller parameter. The questions calculate values like maximum stress, stress ratio, stress range, and allowable stress levels for specific materials at given temperatures and lifetimes.

Uploaded by

ARSLAN FALAKCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 11