0% found this document useful (0 votes)

307 views3 pagesAtul Sangole: Key Highlights

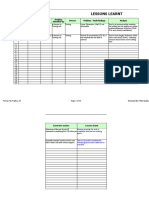

This document provides a summary of an individual's experience in quality assurance and quality control roles. Some of the key highlights include experience investigating and resolving quality problems using tools like 7 QC, 8D, and 5 Why analysis. Additional experience includes implementing ISO standards, conducting audits, supplier development, and ensuring compliance. The individual's career includes roles in quality assurance, quality control management, and quality compliance management for companies in Dubai and India.

Uploaded by

mark kdCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

307 views3 pagesAtul Sangole: Key Highlights

This document provides a summary of an individual's experience in quality assurance and quality control roles. Some of the key highlights include experience investigating and resolving quality problems using tools like 7 QC, 8D, and 5 Why analysis. Additional experience includes implementing ISO standards, conducting audits, supplier development, and ensuring compliance. The individual's career includes roles in quality assurance, quality control management, and quality compliance management for companies in Dubai and India.

Uploaded by

mark kdCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

/ 3