100% found this document useful (3 votes)

310 views6 pagesHaul Truck Fuel Consumption - Published

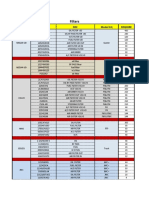

This document summarizes research on haul truck fuel consumption and CO2 emissions under different engine load conditions. The authors establish mathematical relationships between fuel consumption, truck power, and engine load factors. They determine the amount of CO2 emissions and potential costs from future CO2 legislation. Equations are presented to estimate fuel consumption based on truck power and load factor. Data from original equipment manufacturers like Liebherr and Caterpillar show fuel consumption increases linearly with power. Load factors typically range from 10-50% depending on operation type.

Uploaded by

Ahmed IdiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (3 votes)

310 views6 pagesHaul Truck Fuel Consumption - Published

This document summarizes research on haul truck fuel consumption and CO2 emissions under different engine load conditions. The authors establish mathematical relationships between fuel consumption, truck power, and engine load factors. They determine the amount of CO2 emissions and potential costs from future CO2 legislation. Equations are presented to estimate fuel consumption based on truck power and load factor. Data from original equipment manufacturers like Liebherr and Caterpillar show fuel consumption increases linearly with power. Load factors typically range from 10-50% depending on operation type.

Uploaded by

Ahmed IdiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 6