Standard Operating Procedures

Uploaded by

AnilZapateStandard Operating Procedures

Uploaded by

AnilZapateVersion #:

1

{Logo} {Organization} {Document #: }

Page 1 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

1. Introduction

1.1 Background

This information has been developed to assist federal agencies in the development

of safety and health training and is intended to assist Federal Agencies as they strive to

improve workplace health and safety. While we attempt to thoroughly address specific

topics or hazards, it is not possible to include discussion of everything necessary to

ensure a healthy and safe working environment in a document of this nature. Thus, this

information must be understood as a tool for addressing workplace hazards, rather than

an exhaustive statement of an employer’s legal obligations, which are defined by statute,

regulations, and standards. Likewise, to the extent that this information references

practices or procedures that may enhance health or safety, but which are not required by a

statute, regulation, or standard, it cannot, and does not, create additional legal obligations.

Finally, over time, OSHA may modify rules and interpretations in light of new

technology, information, or circumstances; to keep apprised of such developments, or to

review information on a wide range of occupational safety and health topics, you can

visit OSHA’s website at www.osha.gov.

This Standard Operating Procedure (SOP) is intended as a template that Federal Agencies

can use to improve their safety and health training. It may be useful for Federal Agencies

to develop other policy and procedures as a companion to this SOP. Furthermore, the

appendices contain references and documents that do not apply universally to all Federal

Agencies. The intent of this document is to provide research that can be tailored to the

specific agency so that the training developed can promote safe and healthy workplaces.

1.2 Purpose

This document establishes procedures that govern safety and occupational health (OSH)

training, including training management, development, delivery, evaluation, and record

keeping for personnel working at {organization}. This training standard operating

procedure (SOP) is intended to document the {organization’s} commitment to provide

not only training that is required by regulation (federal, state, local) or policy but also to

affirm the {organization’s} commitment to continued OSH excellence. At stake are

injuries and illnesses that occur to our personnel because personnel are not properly

trained to do the jobs assigned to them.

This SOP fulfills the requirements of {name of Safety and Health Management System

(SHMS), e.g. OHSAS 18001:2007 or ANSI/AIHA Z-10:2012} for identification of

competency requirements associated with those personnel who work in jobs that involve

implementing, maintaining and/or improving Safety and Health Management System

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 2 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

(SHMS) components; and/or apply OSH operational controls. This SOP was also adapted

from ANSI/ASSE Z490.1 (2009) as it relates to consensus criteria for accepted practices

in safety and health training. This SOP also aligns with {other orders or guidelines related

to activities associated with training requirements}.

1.3 Objectives

The following objectives will be addressed in this SOP:

• Presentation of unambiguous and relevant safety and health training

requirements appropriate for each position and individual;

• Criteria used to establish relevance of proposed training to required

competencies;

• Compliance with federal, state and local regulatory safety and health training

requirements as well as agency/regional policy;

• Clear roles and responsibilities for management and staff charged with

providing safety and health training;

• Factors that shall be considered when choosing training coursework/providers

to help assure training is of high quality;

• Documentation and tracking that is readily accessible and allows the safety

and health professionals, employees and their managers to access the status of

an individual’s training in real time.

• Documentation and tracking that allows management to assess the

effectiveness of the training program.

1.4 Scope

This procedure applies to any kind of training completed by personnel employed at

{organization} where work performance includes training required by regulation or

statute, or training helps ensure the fulfillment of OSH and/or SHMS-related duties,

responsibilities and competence of personnel.

2. Activities Affected

All operations within {Organization’s} SHMS scope.

3. Related Documents and Forms

3.1 {Organization’s} SHMS Manual, Section {#.#}

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 3 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

3.2 Relevant clauses of SHMS standard (e.g. OHSAS 18001:2007 clause 4.4.2,

Competence, Training and Awareness, ANSI/AIHA Z-10:2012 clause 5.2

Education, Training, Awareness and Competence)

3.3 Safety and Health Management Plans

3.4 Work Control Plan Review Form

3.5 {Organization’s} Safety and Health Program Guideline (Date)

3.6 {Organization’s} Safety and Health Guideline for Job Hazards Analyses (Date)

3.7 Code of Federal Regulations, Title 29, Parts 1910, 1926, and 1960

3.8 {Organization’s} Order ####.#, Safety and Health Management Program

3.9 OSHA Publication 2254, Training Requirements in OSHA Standards and

Training Guidelines

3.10 ANSI/ASSE Z490.1 (2009) Criteria for Accepted Practices in Safety, Health, and

Environmental Training

3.11 Designing and Delivering Effective Training, Susan M. McMaster, CIT, National

Environmental, Safety and Health Training Association, 2004.

4. Definitions

4.1 Competency: Capability to minimize the risk to safety and health though system

effectiveness and individual performance.

4.2 Control: Physical or administrative action, or a combination of these, applied to a

given operation or activity that reduces the actual or potential risks associated

with identified hazards of that activity or operation. A control is applied to

eliminate and/or reduce risks to acceptable levels, if possible and practical.

Training is considered an administrative control.

4.3 Formative assessment: Assessment techniques used by training providers

during learning activities to improve learning content and trainee performance.

4.4 Hazard: Source, situation or act with a potential for OSH consequence in terms

of human injury or ill health/illness, or a combination of these. It also applies to

the potential for damages to or destruction of {organization} property or other

assets.

4.5 Health training: Any activity provided to personnel to gain, improve, or retain

knowledge, skills, or abilities related to the adaption of work to the worker and/or

the worker to the job, e.g. ergonomics training and wellness training; or, training

related to health hazards.

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 4 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

4.6 Ill health or illness: Identifiable, adverse physical or mental condition arising

from and/or made worse by a work action, activity and/or work-related situation.

4.7 Learning objective: A statement in specific and measurable terms that describes

what the learner will know or be able to do as a result of engaging in the learning

activity.

4.8 Personnel: All managers, employees, contractors and subcontractors, grantees,

interns, volunteers or others who may be involved with any of the work actions

performed in or on the facilities or involved with the organizations managed field

work.

4.9 Risk: Combination of the probability of an occurrence of an OSH consequence

and the severity of that consequence that can be caused by a hazard.

4.10 OSH Management Plans (SHMPs): Written plans which guide achievement of

established objectives and targets, and are directly linked to them. SHMPs contain

details on the resources (e.g., financial, human, and technological) and timeframes

to accomplish the objectives and targets. They also contain information describing

the approaches and strategies for achieving objectives and targets, as well as

performance indicators, applicable operational controls, roles and responsibilities

to accomplish tasks, and competency requirements for individuals to accomplish

those tasks. The SHMP ties many elements of the SHMS together (e.g., priority

hazards and risks, objectives and targets, resources, responsibilities, and

capabilities) and provides an integrated view of the disparate requirements in the

SHMS.

4.11 Safety training: Any activity provided to personnel to gain, improve, or retain

knowledge, skills, or abilities related to helping them to become more safety-

conscious in aspects of safety.

4.12 OSH consequence: Any adverse change to an employee’s, grantee’s, student’s,

contractor’s or visitor’s health or well-being resulting from the organization’s

facilities, operations, activities, products and/or services.

4.13 Summative assessment: The trainee is administered a test which is designed to

summarize what has been learned.

4.14 Work control plan (WCP): A document that includes detailed information

about particular work actions (recurring or non-recurring), and provides

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 5 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

identification of the hazards and risks associated with those work actions.

Additionally, the document will include or reference controls that define the

necessary actions that will be taken during conduct of the work actions to

eliminate, avoid and/or minimize the identified hazards and risks. The WCP

requires preparation, review, approval, maintenance and/or closure according to

this procedure.

4.15 Workplace: Any physical location in which work-related activities of the

organization are performed under the control of the organization. This includes

those activities involved with field work, personnel in transit (plane, train,

automobile) or other non-traditional locations or situations in which the

{organization} employees, or those working on the {organization’s} behalf,

complete work actions.

5. Roles and Responsibilities

5.1 Managers and Supervisors

5.1.1 Are ultimately responsible for assuring that an appropriate level of

effective health and safety training is occurring within or originating from

their organizations.

5.1.2 Supervisors shall assure that an employee does not perform work prior to

receiving appropriate work-related training.

5.1.3 Supervisors shall assure that changes in methods or introduction of new

analyses are evaluated for changes in training requirements and that any

changes are included in the Work Control Plan and communicated to the

Health and Safety Manager.

5.1.4 Management shall review the results of safety audits for site compliance.

5.2 Safety and Health Managers shall:

5.2.1 Ensure that sources of training are of high quality and appropriately

address training needs;

5.2.2 Monitor training records to make certain that the type of training and

training frequency required by statute/regulation is occurring;

5.2.3 Conduct/oversee training as appropriate;

5.2.4 Update training requirements per job hazard analyses and work control

plans or as mandated by regulation or statute;

5.2.5 Maintain documentation of training records.

5.3 Site Employees:

5.3.1 Shall comply with training requirements by attending training germane to

their job assignment.

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 6 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

5.3.2 Should be pro-active in identifying areas for which they believe training

should be enhanced/upgraded to allow them to understand and manage the

risks associated with their job assignment.

5.3.3 Shall check their on-line training records for accuracy.

6. Planning for Training

Fundamental in planning for training is the identification of competency requirements and

methods (including training) which may be used to obtain competency. As training is

coordinated and implemented, competency can be reassessed from lessons learned throughout

the process and a focused evaluation of the effectiveness of completed training. The following

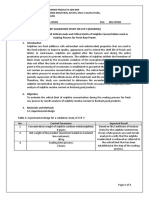

figure portrays this management system approach for ensuring competency and effective

training, and identifies corresponding sections/paragraphs in this SOP.

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 7 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Identify positions with OSH/SHMS duties

6.1.1

Determine baseline levels of

education, experience & training

6.1.2

Define core competency

requirements for each position

6.1.3

Plan

Determine training and other

competency assurance methods

6.1.4

Identify training and other actions

needed by the individual

6.1.5

Identify training goals and

objectives

6.1.6

Coordinate, implement, and Monitor

Do monitor competence training

actions

Feedbac

k

Check

Evaluate effectiveness of

competence/training actions

8

Lessons learned

Act 8.2

Figure 01: Ensuring Competency

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 8 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

6.1 The following process shall be used to determine what training or other actions

are needed:

6.1.1 Identify all positions (not individuals) in the organization with

OSH/SHMS duties and responsibilities. There are many sources for

identifying these positions, e.g., position descriptions, knowledge among

supervisors or other management personnel, OSH/SHMS procedures, and

SHMPs among others.

6.1.2 Determine relevant and necessary baseline levels of education, experience

and training that help define competence for each of these identified

positions, i.e. baseline competency requirements for a given position. This

step should include an analysis of an appropriate progression in levels of

education, experience and training according to grade/pay bands and for

supervisory/non-supervisory positions. Sources of information include

those listed in paragraph 6.1.1; review of job vacancy announcements;

documented roles, responsibilities, authorities and accountabilities;

discussions with supervisors, managers and others with extensive

experience; official career maps and ladders; OSHA regulations; OPM

qualification standards, Department of Defense resources, American

National Standards Institute (ANSI) and American Society of Safety

Engineers (ASSE) standards and resources, National Fire Protection

Association guidance, National Electrical Code guidance, and the Board

of Certified Safety Professionals resources.

6.1.3 Define the core competence requirements for each identified position.

An example of the competency requirements developed for a specific

position is provided at Appendix A, OSH Core Competencies for Facility

Manager. This form or a similar form should be used to identify core

competencies for each identified position.

6.1.4 Identify training or other types of competence-assurance materials or

action options that are available – create new materials or relevant actions,

if necessary. Some training may be specified by regulation, other types of

training may be considered necessary according to the local OSH

program/SHMS. Appendix B lists categories of federal employees and

their OSH training requirements according to 29 CFR 1960. Appendix C

provides a list of training courses for a national organization. Mentoring,

cross-training, temporary assignments, formal education or career

development programs are other available action options. Professional

associations and their certification programs may be appropriate means of

assuring competency for certain positions such as in the Safety and

Occupational Health Management series, GS- 0018:

• Board of Certified Safety Professionals (BCSP) – www.bcsp.org

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 9 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

o CSP – Certified Safety Professional

• American Board of Industrial Hygiene (ABIH) – www.abih.org

o CIH - Certified Industrial Hygienist

• American Board of Health Physics (ABHP)

o CHP - Certified Health Physicist

Lists should be developed of training and competency requirements for

specific positions and for groups of employees. Examples of these lists are

provided at Appendix D. Ultimately, a master training plan that identifies

competencies, knowledge, skills, and abilities, recommended education,

training, assignments, and self development opportunities should be

developed for each position.

6.1.5 Determine training or other appropriate actions that are needed by the

individual to fulfill the duties and responsibilities and ensure personnel

competence.

• A skills assessment based on criteria in master training or career plans

should be conducted for new job assignments.

• New employees typically must complete training requirements before

performing related work tasks, and an initial safety and health training

course covering baseline 29 CFR 1960 elements (as listed in Appendix

E) should be provided within the first 2 weeks of employment.

• Associated actions such as medical surveillance and respirator fit

testing should also be identified based on regulatory requirements,

WCPs, job hazard analyses, work site characteristics, etc. These

associated actions should be listed on work-specific forms such as the

WCP provided at Appendix F.

• Previous training or experience should be considered. For example, the

type and amount of HAZWOPER training is dependent upon what

training and experience has already occurred. Some types of refresher

training may not be required if an appropriate understanding of the

learning objectives can be demonstrated.

• Perspectives of employees, their supervisors/managers, and

subordinates are helpful in determining what training or other actions

are appropriate. For example, discussions with those involved with

permit-required confined space entry can provide information as to

whether there continues to be an effective understanding of each team

member’s roles and responsibilities, whether specific procedures are

reasonable for the team, whether proper equipment is available, and

whether previous training has been valuable. Observation of unsafe

behavior may initiate on-the-job training for vehicle operator. Training

may be required to ensure OSH requirements are communicated as

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 10 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

intended for some unique cultures or languages. Some employees may

have special abilities or disabilities, or motivational issues which may

affect the amount and type of training required. Where feasible

training should take into consideration these factors.

• Systems for career/developmental tracking (including supervisor and

mentor recommendations and corresponding employee actions) are

recommended to assure appropriate progression in safety and health

assignments and responsibilities.

6.1.6 Identify relevant training goals and objectives. This may require

modifications to Individual Development Plans, prioritizing training

according to regulatory and professional requirements, and the availability

of personnel and suitable providers. Sources of information are

communications from supervisors/employees, previous training reports,

skill assessment forms, existing systems for career tracking, policy and

procedures for competency development, and competency-based human

capital strategic plans. Summary reports such as one at Appendix G should

be developed to assist supervisors and employees in completing

requirements during the calendar year.

6.2 Training shall be conducted by qualified provider(s) that meet at least one of the

following conditions:

• Nationally recognized source of training such as the National Safety Council;

• An industry recognized training source;

• Third-party accredited training source which is accredited by an organization

that offers certification or approval, for example, a training provider for first

aid training which is certified by the American Red Cross, the American Heart

Association, American Safety and Health Institute; or a federal or state

approved training provider for an asbestos training program, as defined in the

revised Model Accreditation Plan (40 CFR, Part 763);

• Training product provided by a federal, state or local governmental agency

such as EPA’s power points developed to train employees about chemical

warfare agents;

• Training product provided by an accredited college or university;

• Trainer who is considered qualified by the safety and health manager as a

result of education, training or experience that demonstrates current subject

matter expertise and competency in delivery skills appropriate to adult

learning (training materials can be in-house or commercial products).

6.3 Trainers shall develop written lesson plans or course guides which meet the

minimum requirements identified on the lesson plan form (including comments)

at Appendix H.

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 11 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

• Learning objectives shall consider the training background and experience of

the trainee and be SMART (Specific, Measureable, Achievable, Reasonable,

and Timely)

6.4 Appropriate individuals in the organization (e.g. the safety and health manager or

training coordinator) shall identify the evaluation method(s) to be used, e.g.

perspectives from the trainee, trainer, workplace, and/or organization prior to

training delivery using a form such as the one provided at Appendix I.

6.5 The {organization} shall provide sufficient resources for training for each fiscal

year.

6.6 When relevant, training hours completed in the last quarter of the year may be

forwarded to the next year’s training requirements if total required hours of

training for the current year have been completed.

7. Conducting Training

7.1 Training shall be conducted in a timely manner based on regulatory and agency

requirements, and organizational priorities.

7.2 Competency must be assured. Each new hire must complete those training

requirements identified by their position description before performing a task

associated with a training requirement.

7.3 Training delivery requirements are identified on the delivery record form at

Appendix J. Trainers and/or training coordinators may use this form or a similar

form at least meeting these requirements.

8. Evaluating Training

8.1 Training management/administration, methods, and results shall be evaluated.

8.1.1 Management /Administration

• {Frequency (e.g. quarterly or annual)} internal audits shall be used to

evaluate this SOP for the adequacy of the written accountability

system and the training processes. The following parameters will be

part of this assessment:

o Training type and frequency are on track for required training to be

complete in the FY for which it is scheduled (80% on time +/- 2

month window).

o 10% of tracked employees are at least 95% accurately recorded as

verified by employee concurrence with training manager records.

o All site employees have met at least the FY 8.0 hour site health and

safety training requirement as verified through training

database/spreadsheet.

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 12 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

•{Frequency (e.g. quarterly or annual)} internal audits shall also

include an evaluation of the adequacy of the training resources,

facilities, equipment, and records through discussions with

management and training providers, and review of training evaluation

records.

8.1.2 Methods

Learning objectives, content, and effectiveness shall be evaluated after

each training event, by the safety and health manager/training coordinator

and the training provider.

8.1.3 Results

Competence, needs assessment, professional/career development, annual,

long-term (vision focus), and strategic (strategy focus) training plans,

overall effectiveness.

• Survey (SF-003 Employee Safety Training Survey) of all site

employees between June and October to assess if they believed that

training was adequate for their needs and to solicit suggestions for

training needs in the coming FY.

• Review of WCP’s/JHA’s generated in the FY shows 100% update of

training requirements by job description identified in these documents.

• Recommendations of the Health and Safety Committee;

• Management requests/responses to the {organization’s} changing

mission.

• A key measure of the effectiveness of the Training Program will be the

number of work-related accidents, illnesses and near misses. The

{organization} goal is zero work-related accidents and illnesses.

• {Frequency (e.g. quarterly or annual)} internal audits shall be used to

evaluate the overall effectiveness of the training curriculum/program

and reasonableness of future plans.

• Annual SHMS management reviews will include audit findings of the

training program, including the adequacy of the training resources,

facility, equipment, and future plans taking into consideration

changing missions and competing priorities.

8.2 Continuous Improvement/Updates to Program Requirements

The following resources will be used to assure continuous improvements and

updates to the Health and Safety Training Program.

• {Organization} issued updates for federal rules and regulations;

• {Other, e.g. State} issued updates for rules and regulations;

• Employee Safety Training Surveys;

• Information from training evaluations;

• Recommendations of the Health and Safety Committee;

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 13 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

• Management requests/responses to the {organization’s} changing mission.

9. Documentation and Record Keeping

9.1 Ensure training and competency requirements are documented and records are

kept.

• As the competence requirements and training needs are determined they

must also be recorded in position descriptions, procedures, plans, manuals,

etc.

• Records must be maintained that demonstrate each individual assigned to a

specific position that includes OSH/SHMS responsibilities fulfills the

necessary competence requirements on initial assignment to the position.

• Training records shall use the standardized course titles at Appendix C. The

{organization} training manager shall be contacted to add new course titles

to the list.

• All competence and training records shall be maintained and protected in

accordance with {organization’s} records management procedure for

meeting regulatory requirements for availability, disclosure, confidentiality,

and protection of trade secrets.

9.2 Training certificates shall meet the minimal information requirements shown on

the sample training certificate at Appendix L.

9.3 Personnel responsible for the development of training records must have a clear

understanding of the requirements for the record and record retention skills. They

must also possess technical expertise and direct experience related to the record,

or ensures the record is reviewed by those that have relevant expertise or

experience. These qualifications must be verified by management representatives

that oversee record development before record development begins and during

program assessments.

9.4 The records generated by this SOP include the following.

9.4.1 Job-Specific OSH Core Competencies (Example: Appendix A)

9.4.2 List of training courses (Example: Appendix C)

9.4.3 Training/Competency Lists for specific positions/groups of employees

(Examples: Appendix D)

9.4.4 Training portion of Work Control Plans (Example: Appendix F)

9.4.5 Annual Training Summary Report (Example: Appendix G)

9.4.6 Lesson Plan (Appendix H)

9.4.7 Training Delivery Record (Appendix I)

9.4.8 Training Evaluation Record (Appendix J)

9.4.9 Training Certificate (Appendix K)

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 14 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Document Change History

Document Change History

Version Status Date Name & Title

Location of Change History

# (I, R, C) Approved Author(s) Approving Officials

1 I {Date} N/A Reviewer(s):

Health and Safety Committee

Last, First Name Members

OSH Manager

Approver:

Last, First

OSH Management Representative

Version #: version number of this document.

Status: I = Initial, R= Revision or C = Cancelled

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 15 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

– Appendix A –

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

SAFETY COMPETENCIES

Lockout/tag out (LOTO) Safe work: LOTO is mentioned in the 1910.147 Control of

(Awareness and ability following: {Reference to specific Hazardous Energy

to use LOTO) paragraphs in PD, JHA, etc.} Training requirement at

1910.47(c)(7)

Safe work at heights Safe work: Ladder use is mentioned in 1910.25 Portable wooden 1926 Subpart M Fall Protection

(Ladder safety, scaffold the following: {Reference to specific ladders NFPA 780: Standard for Installation of Lightening

safety, roof safety, aerial paragraphs in PD, JHA, etc.} 1910.26 Portable metal Protection Systems

lifts, use of harnesses ladders

and lifelines) 1926.1053 Ladders

1910.28 Safety requirements

for scaffolding

1926 Subpart L Scaffolds

1910.23 Walking Working

Surfaces

1926.104 Safety Belts,

lifelines, and lanyards

1910.67 Powered Platforms,

Manlifts, and Vehicle-

Mounted Work Platforms

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 16 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

1926.453 Aerial Lifts

Machine injury Safe work: Tasks suggesting the need 1910.212 General machine

awareness for this include: {Reference to specific guarding requirements

(Machinery hazards, paragraphs in PD, JHA, etc.}

burns, belt guards and

precautions for

removing guards and

working around

machinery)

Electrical Safety Safe work and safe facility: Tasks 1910 Subpart S Electrical Other NEC or NFPA consensus standards in effect

(Including hazardous suggesting the need for this include such as NFPA 70E arc flash code

(classified) locations) {Reference to specific items in PD, JHA,

etc.}

Confined Space Safety Safe work: {Reference to various tasks 1910.146 Permit-required

(Hazards and in PD, JHA, etc. Also, provide reference confined spaces

precautions for safe to documents which describe work in

entry) permit-required confined spaces}

HEALTH HAZARD COMPETENCIES

Noise and Hearing Safe work: Various throughout 1910.95 Occupational Noise

Protection Refers to work in noisy places, 85 Exposure

(Including use of decibels or higher with ear protection

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 17 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

controls and PPE)

Personal Protective Safe work: PPE mentioned in 1910.132 PPE General

Equipment including {Reference to various tasks in PD, JHA, Requirements

Respirators etc... Provide reference to other 1910.135-138

(selection, use, fit, documents which describe work 1910.134 Respiratory

maintenance) requiring PPE, and associated programs Protection

such as the local respirator program, or

polices for work in dusts, oils, fumes,

and hood use etc.}

Hazard Communication Safe work and Safe facility: MSDS’s 1910.1200 Hazard

(Chemical hazards, mentioned in {reference to specific Communication

including H2S from locations of MSDS’s and Hazardous

sewage injectors, and Communication Program}

use of MSDS and SDS)

Mold awareness Safe work and Safe facility: Tasks -NIOSH Guidance: Preventing Occupational

(Health effects, suggesting the need for this include: Respiratory Disease from Exposures caused by

precautions and controls {Reference to specific items in PD, JHA, Dampness in Office Buildings, Schools, and Other

to protect O&M workers etc.} Nonindustrial Buildings.

and occupants) http://www.cdc.gov/niosh/docket/review/docket

238/pdfs/05-IEQ-ALERT-3-30-11.pdf

-EPA Guidance: Mold Remediation in Schools and

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 18 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

Commercial Buildings

http://www.epa.gov/mold/pdfs/moldremediatio

n.pdf

Legionella awareness Safe work and Safe Facility: Tasks -The American Society of Heating, Refrigerating

(Health effects, suggesting the need for this include and Air-Conditioning Engineers' ASHRAE

precautions and {Reference to specific items in PD, JHA, Guideline 12-2000, Minimizing the Risk of

measures to protect etc.} Legionellosis Associated with Building Water

building technicians and Systems

occupants) -ASHRAE Standard 188: Prevention of

Legionellosis Associated with Building Water

Systems (to be released in summer of 2012)

Spill Clean up Safe work and Safe facility: Tasks 1910.120 (e) Hazardous Waste

(Serving as “first suggesting the need for this include: Operations and Emergency

responder” for chemical {Reference to specific items in PD, JHA, Response

spills - Knowledge of etc.}

counter spill & clean-up

operations, including for

diesel fuel)

Refrigerant (CFC) Safe work and Safe facility EPA CFR 82.161 certification

awareness for technicians.

(Refrigerant hazards and

procedures)

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 19 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

Heat and Cold stress Safe work: Various tasks. See NIOSH heat stress guidance at

awareness {Reference to specific items in PD, JHA, http://www.cdc.gov/niosh/topics/heatstress/

etc. for tasks that include work in high and OSHA cold stress guidance at

temperatures (85-130F) and low http://www.osha.gov/SLTC/emergencypre

temperatures (0-45F)) } paredness/guides/cold.html

Lead awareness Safe work and safe facility: Various 1910.1025 Lead 1926.62 Lead

(Lead in old solder, repair tasks (Potential upcoming requirements related to EPA

other uses of lead in {Reference to specific items in PD, JHA, Renovation, Repair, and Painting Program for

buildings; non-lead etc.., or, e.g., a list of brazing and Public and Commercial Buildings: see

solder alternatives) soldering equipment} http://www.regulations.gov/#!documentDetail;D

=EPA-HQ-OPPT-2010-0173-0001;oldLink=false

PCB awareness Safe work and Safe facility: Tasks See EPA PCB spill and disposal EPA Proper Maintenance, Removal, and Disposal

(Presence in old ballasts, suggesting the need for this include: regulations at of PCB-Containing Fluorescent Light Ballasts

transformers, and {reference(s)} http://www.epa.gov/epawast http://www.epa.gov/osw/hazard/tsd/pcbs/pubs/

window caulks) e/hazard/tsd/pcbs/pubs/laws. ballasts.htm

htm EPA PCBs in Caulk in Older Buildings

http://www.epa.gov/pcbsincaulk/

EPA Contractors: Handling PCBs in Caulk During

Renovation

http://www.epa.gov/pcbsincaulk/caulkcontractor

s.htm

Asbestos awareness Safe work and Safe facility: Tasks 1910.1001 1926.1101 Asbestos

(Health effects and suggesting the need for this include: Training requirements at EPA Managing Asbestos in Place: How to Develop

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 20 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

presence in older {reference(s)} 1910.1001(i)(7) and Maintain a Building

building components Asbestos Operations and Maintenance (O&M)

such as boiler and pipe Program

insulation, http://www.epa.gov/asbestos/pubs/m

gaskets, floor tiles, and anagement_in_place.html

sound and heat proofing

materials.

Understanding how

disturbance can occur

and safe work

procedures. )

Musculoskeletal Safe work: Various tasks. (e.g., {JHA, or OSHA 2250: Principles of Ergonomics applied to

Disorder awareness other reference} mentions lifting 100 Work-Related Musculoskeletal and Nerve

pounds maximum and working with Disorders

hands and arms over head level.)

LIFE SAFETY AND SECURITY COMPETENCIES

Management of Fire Management and safe facility: Duties All of Subpart L: Fire NFPA 72: National Fire Alarm & Signaling code

Protection and Life related to management include, e.g.: Protection NFPA 20: Standard for the Installation of

Safety Access Control (e.g. Fire detection systems, Stationary Pumps for Fire Protection

(Hazards, systems, Fire and Life Safety Systems employee alarm systems, NFPA 25: Standard for Inspection, Testing &

maintenance, testing. Preventive Maintenance automatic sprinkler systems) Maintenance of Water-Based Fire Protection

Hot work (e.g. use of Building Systems Systems.

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 21 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

torches), flammable 1910.106(b) Flammable and

NFPA 13; Standard for Installation of Sprinkler

storage, and fire watch.) Combustible liquids Systems.

NFPA 80: Standard for Fire Doors and Other

Opening Protectives

NFPA 102: Standard for Smoke Door

Assemblies and other Opening Protectives

NFPA 22: Standard for Water Tanks for Private

Fire Protection

NFPA 101: Life Safety Code

Test procedures/protocol as determined by local

Authority Having Jurisdiction.

Local Building and Fire Prevention Codes

Occupant Emergency Management and safe facility. Tasks National Security Presidential GSA Guide: Occupant Emergency Plans:

Plans and Continuity of suggesting the need for this include: Directive-51/Homeland Development, Implementation, and Maintenance

Operations Plans a) “Manage Security Systems” Security Presidential Directive- http://www.gsa.gov/graphics/pbs/

(Developing, 20 (NSPD-51/HSPD-20) OEP_Guide.pdf

implementing, and FEMA Continuity of Operations webpage

maintaining emergency guidance

plans) http://www.fema.gov/about/org/ncp/coop/index

.shtm

SAFETY AND HEALTH MANAGEMENT COMPETENCIES

General Facility Management and safe facility. Tasks Part 1904- Recording and

Occupational Safety and suggesting the need for this include, Reporting Occupational

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 22 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

Health Management: e.g.: Injuries and Illness

-Safety and health a) “Safety Requirements“ Part 1960 – Basic Program

hazards faced by b) “Conduct a job/hazard assessment Elements for Federal

building operations and for the task” Employees

maintenance employees c) “Manage Safety Programs”

-OSH management d) “Develop a HAZMAT reduction

-Accident investigation strategy”

and basic hazard and e) Also, lists of “training skills”

risk evaluation

-How to develop basic

health and safety

procedures

-OSHA recordkeeping

forms

-Federal Safety and

Health professional

resources

-Safety training topics

-Workers Compensation

requirements

-OSH program

requirements (hearing

protection, respiratory

protection, fall

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 23 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

protection, etc.)

Building Services Management and safe facility. The See EPA NIOSH: Fatal Injuries among Landscape Services

hazards, safe practices, tasks suggesting the need for this http://www.epa.gov/oppfead Workers

and management include: 1/safety/applicators/privcom http://www.cdc.gov/niosh/docs/2008-144/

(-Landscaping hazards a) “Manage landscaping (and grounds) m.htm http://www.cdc.gov/mmwr/preview/mmwrhtml/

-Janitorial hazards and program” for rules and references to mm6017a3.htm?s_cid=mm6017a3_w

cleaning chemicals. b) “Manage janitorial program” state laws for pesticide See OSHA Topic page

Effects on workers and c) “Manage Pest Control program” applicators http://www.osha.gov/dcsp/products/topics/clea

IAQ d) “Manage Facility fleet” ningindustry/standards.html

-Pesticide hazards and See EPA guidance: Greening your purchase of

effects on applicators Cleaning products

and IAQ http://www.epa.gov/epp/pubs/cleaning.htm

-Motor vehicle hazards

and safe practices)

Construction and Management and safe facility. The 1926 standards for Building Air Quality

Renovation hazards and following tasks suggesting the need for Construction A Guide for Building Owners and Facility

safe practices this include: Managers

(-Knowledge on how to a) “Managing tenant build outs” http://www.epa.gov/iaq/largebldgs/baq_page.ht

plan a safe renovation. b) “Initiating a facility project”, or m

-Knowledge on c) “Managing impacts of project on

renovation-related existing facility”.

“Prevention through

Design” (e.g. using roof

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 24 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

repair to have

permanent anchors for

fall prevention installed)

-Knowledge on how to

monitor project safety

and health

-Knowledge on potential

for renovation to affect

indoor air quality and

practices to minimize

this.)

Sustainable Program Management and safe facility. The

Management tasks suggesting the need for this relate

Extent of responsibility to managing sustainable programs,

depends on how much is includes the following:

shared with a) Develop green procurement

Sustainability Manager program

b) Develop HAZMAT reduction strategy

c) Develop a green cleaning program

IAQ awareness Relates to management of mechanical Building Air Quality

(A variety of building systems (HVAC, plumbing, etc.) A Guide for Building Owners and Facility

operations and Managers

maintenance practices http://www.epa.gov/iaq/largebldgs/baq_page.htm

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 25 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

and conditions can

adversely affect IAQ for

building occupants)

SPECIALIZED COMPETENCIES

Laboratories Safe work, management, and safe 1910.1450 Occupational ANSI Z358.1-2004, Emergency Eyewash and

(Facilities that include facility. Exposure to Hazardous Shower Equipment

labs will require Lab operations affect numerous Chemicals in Laboratories ANSI Z9.5-2003, Laboratory Ventilation

additional specialty building systems and maintenance NFPA 45: Standard on Fire Protection for

competencies related to issues. Laboratories Using Chemicals

common lab safety OSHA Laboratory Safety Guidance

issues such as: mercury, http://www.osha.gov/Publications/laboratory/OS

radionuclides, HA3404laboratory-safety-guidance.pdf

maintenance of safety

showers, lab hoods, and

toxicants that could be

introduced into the

ventilation system from

lab operations.)

Green and Vegetated Safe work, management, and safe 1910.23 Walking Working

roofs facility. surfaces

(Facilities that include Green and vegetated roofs require 1926 Subpart M Fall

green and vegetated maintenance. Fall prevention Protection

roofs involve additional arrangements and procedures are

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 26 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

safety management needed to assure safe access and safe

duties to assure safe work.

access and (NOTE: Vegetated roof maintenance

arrangements for fall may be contracted out)

prevention.)

Solar installations Safe work, management, and safe 1910.23 Walking Working

(Facilities that include facility. Surfaces

solar installations Solar installations require maintenance. 1926 Subpart M Fall

involve additional safety Fall prevention and electrical safety Protection

management duties to procedures and arrangements are 1910 Subpart S Electrical

assure safe access, safe needed to assure safe access and safe 1926 Subpart K Electrical

electrical work, and work

arrangements for fall (NOTE: Solar installation maintenance

prevention.) may be contracted out)

Wind power installation Safe work, management, and safe 1910.23 Walking Working

(Facilities that include facility. Surfaces

wind power installation Wind power installations require 1926 Subpart M Fall

involve additional maintenance. Fall prevention, and safe Protection

safety management electrical and confined space 1910 Subpart S Electrical

duties to assure safe procedures and 1926 Subpart K Electrical

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 27 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Safety and Occupational Health Core Competencies for: FACILITY MANAGER

Competencies based on a notional description of Facility Manager Responsibilities

Specialized Safety & Relevant to these Duties/Task/Steps Relevant Federal Regulations Other relevant Best Practice or Consensus or

Health knowledge Agency Standard

needed

access, safe electrical arrangements are needed to assure

and confined space safe access and safe work

work, and arrangements (NOTE: wind power maintenance likely

for fall prevention.) to be contracted out)

Forklifts Management 1910.178

(Facilities that use Ensure forklift driver training every 3

forklifts involve years

additional safety

management duties to

assure safe use.)

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 28 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

– Appendix B –

Training Required by 29 CFR 1960 Listed by Employee Category or Group

Employee Category/Group Required Training

Four (4) basic items:

“top management officials” - 1960.54

1. Sec. 19 of the OSH Act,

2. E.O. 12196,

3. 29 CFR Part 1960, and

4. Their Agency’s Safety & Health program.

1

In addition to the 4 basic items “supervisory employees” must receive

“supervisory employees” - 1960.55 training on:

• Supervisory responsibility for safety & health

• Applicable OSH standards

• Procedures for reporting hazards

• Procedures for investigating allegations of reprisal

• Procedures for hazard abatement.

• Training on motivation of subordinates.

1

In addition to the 4 basic items “safety and health specialists” must

“safety and health specialists” - 1960.56 receive training on:

• Technical monitoring, testing, sampling, testing, design, etc.

• Hazard recognition, evaluation and control

• Equipment and facility design

• Analysis of accident, injury and illness data

• Career development plan/program

1

In addition to the 4 basic items “safety and health inspectors” must

“safety and health inspectors” - 1960.57 receive training on:

• preparation of reports and findings

1

In addition to the 4 basic items “collateral duty safety & health

“collateral duty safety and health personnel personnel” must receive training on:

and committee members” - 1960.58

• Procedures for reporting, evaluating and abating hazards;

• Procedures for investigating allegations of reprisal;

• Hazard recognition; and

• Identification and use of OSH standards.

1

In addition to the 4 basic items “employees” must receive training which

“employees and employee representatives” is: “appropriate to the work performed.”

– 1960.59

1

In addition to the 4 basic items “employee representatives” must

receive “specialized training” in hazard recognition and in workplace

inspections.

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 29 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

– Appendix C –

Course Title Applicability Description Frequency Training Hours Records Comments

13 Carcinogens Any employee who works in General awareness Prior to 1-2 hours

29 CFR 1910.1003 an area where the following training and more employee entry

29 CFR 1926.1103 13 carcinogens are advanced training into any area

manufactured, processed, specific to the health containing these

repackaged, released, hazards encountered, materials

handled, or stored. Access to first aid and emergency

these areas should be procedures. See Annual refresher

restricted to authorized 1910.1003(5).

employees.

1) 4-Nitrobiphenyl,

2) alpha-Naphthyl amine

3) methyl chloromethyl ether

4) 3’-Dichlorobenzidine

(and its salts)

5) bis-Chloromethyl ether

6) beta-Naphthylamine,

7) Benzidine

8) 4-Aminodiphenyl

9) Ethyleneimine

10) beta-Propiolactone

11) 2-Acetylamino fluorene

12) 4-Dimethylamino azo-

benezene,

13) N-Nitrosodimethyl amine

Access to Employee All employees Employees shall be Upon initial 15-30 minutes

Exposure and informed of rights to employment

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 30 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Course Title Applicability Description Frequency Training Hours Records Comments

Medical Records exposure and medical

29 CFR 1910.1020 records as described in Annual refresher

the regulation.

Acrylonitrile Each employee potentially Training specific to the Upon initial 1 hour

29 CFR 1910.1045 exposed to acrylonitrile manner of use, assignment to

29 CFR 1926.1145 above the action level. protective clothing, duties

hazards and medical

Each employee whose surveillance. Annual refresher

exposures are maintained

below the action level by

engineering and work

practice controls.

Each employee subject to

potential skin or eye contact

with liquid AN.

Air Monitoring For Field Safety and Health - General Awareness Upon initial 1 hour

Field Activities General Awareness assignment to

- elective course field activities

Air Monitoring For Laboratory Safety and Health General Awareness Upon initial 1 hour

Laboratory Activities - General Awareness– assignment to

required course laboratory

activities

Aircraft Safety Field Safety and Health - General Awareness Upon initial 1 hour

Awareness General Awareness assignment to

– elective course field activities

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 31 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Course Title Applicability Description Frequency Training Hours Records Comments

Altitude Safety Emergency Responders and General Awareness Upon initial 1 hour

Awareness their supervisors. assignment

{Organization-specific}

Employees working at OSH Manual, Physical

altitudes of 8,000 feet or Stress Management

higher [according to

organization-specific policy]

Arc Welding & Any employee who performs General competency Upon initial 1-2 hours

Cutting arc welding and/or cutting. training ensuring that assignment to depending upon

operator

29 CFR 1910.254 the operator is duties and as

qualifications

properly instructed and needed

qualified to operate

the equipment. Also

knowledge of the

requirements of the

standard.

Arsenic - Inorganic Any worker potentially General awareness Upon initial 1-2 hours

29 CFR 1910.1018 exposed to inorganic arsenic training and more assignment to

29 CFR 1926.1118 above the action level or for advanced training duties

whom there is the possibility specific to the health

of skin or eye irritation from hazards encountered, Annual refresher

inorganic arsenic. first aid and medical

surveillance. Also

operations which could

result in exposure.

Asbestos - Any employee who is Varies with duties and Upon initial 8-40 hours The employer shall

Construction potentially exposed in excess types of work. See assignment to maintain all employee

training records for one

29 CFR 1926.1101 of a PEL, and each employee regulation. duties

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 32 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Course Title Applicability Description Frequency Training Hours Records Comments

who performs Class I through year beyond the last date

IV asbestos operations. of employment by that

employer.

Asbestos - Any employee who is Varies with duties and Annual refresher 3-4 hours The employer shall

Construction Annual potentially exposed in excess types of work. See maintain all employee

training records for one

Refresher of a PEL, and each employee regulation.

year beyond the last date

29 CFR 1926.1101 who performs Class I through of employment by that

IV asbestos operations. employer.

Asbestos Awareness Employees who perform Health effects of Upon initial 30 min – 1 hour

29 CFR housekeeping or similar asbestos, locations of assignment to

1910.1001(j)(7)(iv) operations in areas with ACM ACM and PACM in the duties and as

or PACM. building/facility, needed

recognition of ACM and

PACM damage and

deterioration,

requirements in this

standard relating to

housekeeping, and

proper response to

fiber release episodes

Asbestos Awareness Employees who perform Health effects of Annual refresher 30 min – 1 hour

– Annual Refresher housekeeping or similar asbestos, locations of

29 CFR operations in areas with ACM ACM and PACM in the

1910.1001(j)(7)(iv) or PACM. building/facility,

recognition of ACM and

PACM damage and

deterioration,

requirements in this

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 33 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Course Title Applicability Description Frequency Training Hours Records Comments

standard relating to

housekeeping, and

proper response to

fiber release episodes

Asbestos Worker – Any employee with potential Training is specific to Upon initial 1-2 hours

Annual Refresher for asbestos exposure in the hazard and assignment to

29 CFR excess of the PEL or includes health effects, duties and as

1910.1001(j)(7)(i) Excursion Limit. smoking cessation, PPE needed

and engineering

control requirements.

General awareness.

Asbestos Worker- Any employee with potential Training is specific to Upon initial 3-4 hours

General Industry for asbestos exposure in the hazard and assignment to

Initial Training excess of the PEL or includes health effects, duties

29 CFR Excursion Limit. smoking cessation, PPE

1910.1001(j)(7)(i) and engineering

control requirements.

General awareness.

Automated External Voluntary training for Lay Responder/Rescuer As requested 1 hour

Defibrillators (AED)- employees wishing to learn (LRR) Training

Certification use of on-site AEDs

Per FOH guidance,

Source – Guidelines even in the case where

for Public Access large facilities have

Defibrillation self-contained

Programs in Federal emergency medical

Facilities – Office of services systems, it is

Public Health and still advisable to devise

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 34 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Course Title Applicability Description Frequency Training Hours Records Comments

Science, Office of a training program for

the Secretary, HHS LRRs.

and Office of

Government-wide LRRs may include

Policy, GSA. security personnel and

other staff which may

render assistance

during a cardiac arrest.

Basic Program This applies to all Federal Training of safety & Upon initial Various

Elements for Workers who have specific health specialists. assignment to

Federal Employees safety and health functions duties

29 CFR 1960 within their respective Training of safety &

agencies. health inspectors.

Collateral Duty Health and Training of collateral

Safety Employee – required duty safety & health

course officers/safety

committee members.

Training of employees.

Basic Toxicology Employees working with General Awareness Upon initial 1 hour

1926.21(b)(2) toxic or other hazardous assignment to

{Organization- materials in the laboratory or duties

specific order} field operations.

Field Safety and Health -

General Awareness

– required course

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 35 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Course Title Applicability Description Frequency Training Hours Records Comments

Laboratory Safety and Health

- General Awareness–

required course

Benzene Any employee who works in General training and Upon initial 1-2 hours

29 CFR 1910.1028 an area with benzene present training specific to the assignment to

29 CFR 1926.1128 in that area. (Example – in a hazards associated duties

laboratory.) with benzene, and the

contents of the Annual refresher

standard. only if exposures

above the action

level are present

Biological Safety Field Safety and Health - General Awareness Upon initial 1 hour

Awareness General Awareness assignment to

- required course duties

Laboratory Safety and Health

- General Awareness–

required course

Bloodborne Employees with potential Awareness training At time of initial 1-2 hours Training records shall be

Pathogens (BBPs) occupational exposure to which also covers in assignment to maintained for 3 years

from the date on which

29 CFR 1910.1030 human blood or other depth the BBPs, modes tasks where

the training occurred.

potentially infectious of transmission, decon, exposure to

materials. recognizing tasks with bloodborne

exposure and the pathogens is

Field Safety and Health - Hepatitis B vaccine. likely

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 36 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Course Title Applicability Description Frequency Training Hours Records Comments

General Awareness Must have opportunity

- elective course for interactive

questions. Upon changes

Laboratory Safety and Health such as

- General Awareness– modification of

elective course tasks or

procedures or

Collateral Duty Health and institution of

Safety Employees – elective new tasks or

course procedures

affecting the

employee’s

occupational

exposure

Bloodborne Employees with potential See BBP initial training. Annual refresher 1-2 hours

Pathogens (BBPs) occupational exposure to

Annual Refresher human blood or other

29 CFR 1910.1030 potentially infectious

materials.

Boating Safety Field Safety and Health - General Awareness Upon initial 1 hour

Awareness General Awareness - elective assignment to

course field activities

Boating Safety Employees operating Boating Education Upon initial 24-40 hours

Certification Course watercraft as part of their Course provided by US assignment as a

assigned duties. Coast Guard or boat operator

equivalent training

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 37 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Course Title Applicability Description Frequency Training Hours Records Comments

Course requirements vary by such as National

State. OSH managers should Association of State

contact appropriate state Boating Law

agencies. Administrators

(NABSLA). Additional

information available

through {Organization-

specific} Vessel Safety

Manual.

Boating Safety for Captains/masters of Class A Approval by the VMO Initial upon hire 8-16 hours

Class A Vessel vessels who are (or appropriate or assignment to

Operation {Organization} employees or designee) for the

contractors operation of the Recommend

specific type of vessel triennial

for which he or she is competency/

to be the practical

captain/master. The

approval process must

consider total boating

experience and

required knowledge of

the specific craft and

the waters involved.

Butadiene Any employee who is In addition to general Upon initial 1 hour

29 CFR 1910.1051 potentially exposed to 1,3 awareness training assignment to

Butadiene at or above the (Hazard duties

action level or the STEL Communication) the

Uncontrolled when printed: 7/28/2014

For the most current copy, check the {___ list on the (location of electronic file)}

For Internal Use Only

Version #:

1

{Logo} {Organization} {Document #: }

Page 38 of 139

Title: STANDARD OPERATING PROCEDURES FOR Effective Date:

SAFETY AND HEALTH TRAINING MM/DD/YYYY

APPENDIX B

Course Title Applicability Description Frequency Training Hours Records Comments

employer must address Annual refresher

specific hazards and

medical surveillance.

Cadmium Any employee potentially General awareness Upon initial 1-2 hours The employer shall

29 CFR 1910.1027 exposed to cadmium. training and advanced assignment to certify that employees

have been trained by

training specific to the duties involving

preparing a certification

hazards associated potential record which includes

with cadmium, medical exposure to the identity of the person

surveillance, PPE. cadmium trained, the signature of

the employer or the

Annual refresher person who conducted

the training, and the date

the training was

completed. The

certification records shall

be prepared at the

completion of training

and shall be maintained

on file for one (1) year

beyond the date of