0% found this document useful (0 votes)

250 views56 pagesHydraulics: Pipelines & Networks Guide

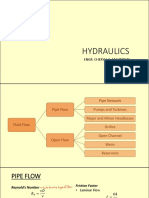

This document discusses pipelines and pipe networks. It begins by defining the key elements that make up water conveyance systems, including pipes arranged in series or parallel, elbows, valves, and other devices. It then provides the following key points:

- Flow through a single pipe is called simple pipe flow and involves applying the energy equation (Bernoulli's equation) to calculate head losses.

- Compound pipe flow occurs when pipes of different diameters are connected in series or parallel. This involves calculating discharge and head losses through each pipe segment.

- Pipes in series involve connecting pipes end to end with different lengths and diameters. Flow is the same in each pipe but head loss is the sum of losses.

Uploaded by

Alok KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

250 views56 pagesHydraulics: Pipelines & Networks Guide

This document discusses pipelines and pipe networks. It begins by defining the key elements that make up water conveyance systems, including pipes arranged in series or parallel, elbows, valves, and other devices. It then provides the following key points:

- Flow through a single pipe is called simple pipe flow and involves applying the energy equation (Bernoulli's equation) to calculate head losses.

- Compound pipe flow occurs when pipes of different diameters are connected in series or parallel. This involves calculating discharge and head losses through each pipe segment.

- Pipes in series involve connecting pipes end to end with different lengths and diameters. Flow is the same in each pipe but head loss is the sum of losses.

Uploaded by

Alok KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 56