0% found this document useful (0 votes)

477 views1 pageWPS-Shell To Shell Joint (CS-CS) .

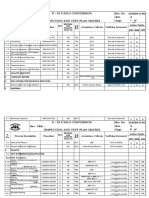

This welding procedure specification outlines the requirements for welding pipe using gas tungsten arc welding (GTAW) and shielded metal arc welding (SMAW) processes. The root pass will be completed using GTAW, while the filling and capping passes will use SMAW. The base metal is ASTM A-36 steel with a maximum plate thickness of 20mm. Filler metals include ER70S-3 for GTAW and E7018 electrodes for SMAW. Welding parameters such as preheat temperature, gas composition, and electrical characteristics are also specified.

Uploaded by

suria qaqcCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

477 views1 pageWPS-Shell To Shell Joint (CS-CS) .

This welding procedure specification outlines the requirements for welding pipe using gas tungsten arc welding (GTAW) and shielded metal arc welding (SMAW) processes. The root pass will be completed using GTAW, while the filling and capping passes will use SMAW. The base metal is ASTM A-36 steel with a maximum plate thickness of 20mm. Filler metals include ER70S-3 for GTAW and E7018 electrodes for SMAW. Welding parameters such as preheat temperature, gas composition, and electrical characteristics are also specified.

Uploaded by

suria qaqcCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

/ 1