100% found this document useful (1 vote)

808 views4 pagesOne Direct Method Statement: Preventative Measures

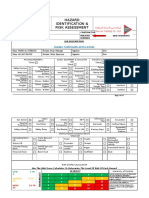

This method statement outlines the procedures for chasing walls to lay electrical cables at OHG Properties. It identifies potential hazards such as electrocution, vibration, noise, dust and asbestos. Personal protective equipment including hard hats, high viz vests, safety footwear, gloves, safety glasses and dust masks are required. The document provides a step-by-step sequence of work and details on permit to work, training, emergency procedures, waste disposal and refueling. It aims to ensure works are completed safely with minimal risk to operatives and the public.

Uploaded by

Ayu Wanda SaraswatiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

808 views4 pagesOne Direct Method Statement: Preventative Measures

This method statement outlines the procedures for chasing walls to lay electrical cables at OHG Properties. It identifies potential hazards such as electrocution, vibration, noise, dust and asbestos. Personal protective equipment including hard hats, high viz vests, safety footwear, gloves, safety glasses and dust masks are required. The document provides a step-by-step sequence of work and details on permit to work, training, emergency procedures, waste disposal and refueling. It aims to ensure works are completed safely with minimal risk to operatives and the public.

Uploaded by

Ayu Wanda SaraswatiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 4