100% found this document useful (1 vote)

429 views5 pagesProcess Control

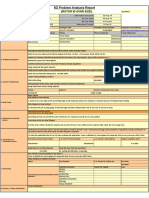

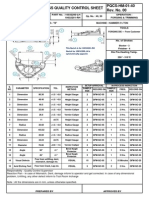

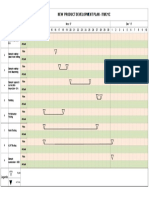

This document outlines an organization's process control procedure. It describes the purpose, scope, responsibilities, and documents related to process control. It also discusses the requirements of relevant ISO and IATF standards. The main sections cover developing process identification, mapping, control, criteria, capability studies, qualification, documentation, and addressing changes and special processes. Product safety measures are also summarized.

Uploaded by

Tuan AnhCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

429 views5 pagesProcess Control

This document outlines an organization's process control procedure. It describes the purpose, scope, responsibilities, and documents related to process control. It also discusses the requirements of relevant ISO and IATF standards. The main sections cover developing process identification, mapping, control, criteria, capability studies, qualification, documentation, and addressing changes and special processes. Product safety measures are also summarized.

Uploaded by

Tuan AnhCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 5