100% found this document useful (1 vote)

825 views46 pagesChapter 4 Molding

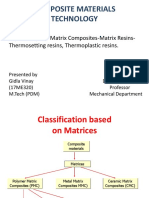

The document discusses molding design and plastic materials. It provides an overview of different types of polymers, including thermoplastics and thermosetting plastics. It also describes common plastic additives and processing methods like extrusion, injection, and blow molding. Blow molding in particular uses air pressure to inflate soft plastic into a mold cavity and is used to make hollow plastic parts.

Uploaded by

Tamirat NemomsaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

825 views46 pagesChapter 4 Molding

The document discusses molding design and plastic materials. It provides an overview of different types of polymers, including thermoplastics and thermosetting plastics. It also describes common plastic additives and processing methods like extrusion, injection, and blow molding. Blow molding in particular uses air pressure to inflate soft plastic into a mold cavity and is used to make hollow plastic parts.

Uploaded by

Tamirat NemomsaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 46