0 ratings0% found this document useful (0 votes)

69 views88 pagesComputerized Tool Path Generation

Uploaded by

henokzewduCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

69 views88 pagesComputerized Tool Path Generation

Uploaded by

henokzewduCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

You are on page 1/ 88

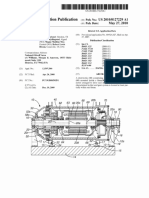

2) United States Patent (10) Patent No: US 8,489,224 B2

Berman et al. (45) Date of Patent: Jul. 16, 2013

(S!) COMPUTERIZED TOOL PATH GENERATION $5529 4 ¢ $1836 toni e018

+ St Romie da joie

5 1096 Jim ta Sise

(5): Mia Bran Yor I) 191356 Jim sis

Joron Oxovansld Cit Shmuel (I) Sree mae

Christopher Calderone, Leviton, PA 2 "atboe Pee a2 oot

(US). Anthony Calderon, Yardley, PA Simm A+ 1bt Aaa worn

& SInI38 A * '82000 Fskman ‘tos

CUUIUD BIS 10200 Summa Zoais0

i Saag Bie ‘S202 Shine “oe

(73) Assignee: Solideam Ltd, Or Yehuda (IL) arse ial ane

Fah ta son

(4) oti: Subject to any disclaimer, the term ofthis Fayactal wis

Palen is extended or ajusted unier 35 S391 158 BL Bacau al

Bsc. tsayey 1 don Sis 2+ 1D2006 Aer os

728to@ aise

(21) Appl. Nos 13/036,726 Tamu Hong eta wea

(Coin)

(22) Filed Reh. 28,2011 omits PUBLICATIONS

«6 Prior Publication Data nln Sesh Rta Wit Ono bth

Tsao ee 7.2012, which isd dig th poco of Apa PCT

1201200087

(51) Int-c. aa

GO6F 19/00 (011.01) (Continued)

(52) US.CL Primary Examiner —Ramesh Patel

USEC su. 700/81; 700159; 700/160; 700173

O0183; 7001190

(58) Field of Classitication Search

usec 700/159-160, 173, 181, 183, 190

29/608. 07; 408/31; 40964, 80, 84, 132; 481/64

‘See application file for complete search history.

(56) References Cited

US. PATENT DOCUMENTS.

ADSSSE A SI988 Kishi etal

ABOTIGE A VI990 Guyder

D880 A #1991. Shinorak 0018

$08,306 4 + 81991 Jepson ro 192

Spoisol A * 211902 Galler eta ro0199

EQSHK43 A * 10:1999 Mads 700176

S297022 A * Vio Watanabe 70086

S363308 A 111904 Gayder

(74) Atorn

Agent, or Firm —Sughrue Mion, PLLC

“7 ABSTRACT

An automated computer implemented method for generating

‘commands for controling «computer numerically controled

machine to fabricate an object froma workpiece the method

including the steps of selecting a maximum permited

engagement angle between a rotating euting tol and the

workpiece, selecting a minimum permitted engagement

angle between the mating eutng tool and the workpiece,

and configuring a too path for the tool relative to the work

piece in which the engagement angle gradually varies

hetwoon the maximum permitted engagement angle and the

rinimum permitted engagement angle.

£80 Claims, 61 Drawing Sheets

US 8,489,224 B2

Page 2

USS. PATENT DOCUMENTS. BOIVOLT862 AL* 712011 Diehleta 00187

7451013 B2* 11/2008 Coleman tal 0173 (OTHER PUBLICATIONS,

7871490 B2* 82009 Diehlet al. 70173

703588 B2* 42010 Honget a. ‘7o0'61 _Masinse. Toll Path Strategies for high Speed Machining. Modem

7831332 B2* 112010 Dell 00190 Machine Shop (Fb. 15,200} cieved on Jl 9, 2012} Revived

000834 B2* 8/2011 Diohlet a 700/190 fom the interes

‘20080265085 Al 10/2008 Dich etal

DOIMOIOISS9 AL 72010 Diehlet a * citod by examiner

US. Patent Sul. 16, 2013 Sheet 1 of 61 US 8,489,224 B2

US. Patent Sul. 16, 2013 Sheet 2 of 61 US 8,489,224 B2

102

100

Yo

O:

1B

FIG.

104

12

US. Patent Jul. 16, 2013 Sheet 3 of 61 US 8,489,224 B2

US. Patent Jul. 16, 2013 Sheet 4 of 61 US 8,489,224 B2

US. Patent Sul. 16, 2013 Sheet 5 of 61 US 8,489,224 B2

US 8,489,224 B2

Sheet 6 of 61

Jul. 16, 2013

US. Patent

ve

US. Patent Sul. 16, 2013 Sheet 7 of 61 US 8,489,224 B2

US 8,489,224 B2

Sheet 8 of 61

Jul. 16, 2013

US. Patent

US. Patent Sul. 16, 2013 Sheet 9 of 61 US 8,489,224 B2

US 8,489,224 B2

Sheet 10 of 61

Jul. 16, 2013

US. Patent

wa

Sz

US. Patent Sul. 16, 2013 Sheet 11 of 61 US 8,489,224 B2

US 8,489,224 B2

Sheet 12 of 61

Jul. 16, 2013

US. Patent

US. Patent Sul. 16, 2013 Sheet 13 of 61 US 8,489,224 B2

FIG. 11-1

m

US 8,489,224 B2

Sheet 14 of 61

Jul. 16, 2013

US. Patent

Z-lt

“Old

out

US 8,489,224 B2

Sheet 16 of 61

Jul. 16, 2013

US. Patent

95

US 8,489,224 B2

Sheet 18 of 61

Jul. 16, 2013

US. Patent

c-mL “Old aul

US 8,489,224 B2

Sheet 20 of 61

Jul. 16, 2013

US. Patent

US 8,489,224 B2

Sheet 22 of 61

Jul. 16, 2013

US. Patent

US 8,489,224 B2

Sheet 24 of 61

Jul. 16, 2013

US. Patent

US 8,489,224 B2

Sheet 26 of 61

Jul. 16, 2013

US. Patent

O6t

c—-Ol

“Old

761

US 8,489,224 B2

Sheet 28 of 61

Jul. 16, 2013

US. Patent

US 8,489,224 B2

Sheet 30 of 61

Jul. 16, 2013

US. Patent

Li QL 9b

veh

Pelz.

Z0%

US 8,489,224 B2

Sheet 32 of 61

Jul. 16, 2013

US. Patent

US 8,489,224 B2

Sheet 34 of 61

Jul. 16, 2013

US. Patent

1617 O61

lz

eH

sl

az vie

US. Patent Jul. 16, 2013 Sheet 35 of 61 US 8,489,224 B2

US. Patent Sul. 16, 2013 Sheet 36 of 61 US 8,489,224 B2

402

400

x“

FIG. 2B

US 8,489,224 B2

Sheet 37 of 61

Jul. 16, 2013

US. Patent

US 8,489,224 B2

Sheet 38 of 61

Jul. 16, 2013

US. Patent

US. Patent Sul. 16, 2013 Sheet 39 of 61 US 8,489,224 B2

Va 400

FIG. 2D-—2

US 8,489,224 B2

Sheet 40 of 61

Jul. 16, 2013

US. Patent

L-4az “Old

ozr—

US. Patent

Jul. 16, 2013 Sheet 41 of 61

vn

FIG. 2E-2

US 8,489,224 B2

US 8,489,224 B2

Sheet 42 of 61

Jul. 16, 2013

US. Patent

b-4@ “Old

US 8,489,224 B2

Sheet 43 of 61

Jul. 16, 2013

US. Patent

ee : a

Lat

="

é€-dé ‘Old

US 8,489,224 B2

Sheet 44 of 61

Jul. 16, 2013

US. Patent

b-9@ ‘Old

US. Patent Sul. 16, 2013 Sheet 45 of 61 US 8,489,224 B2

400

a

26-2

FIG.

US 8,489,224 B2

Sheet 46 of 61

Jul. 16, 2013

US. Patent

L-H@ “Old

US 8,489,224 B2

Sheet 47 of 61

Jul. 16, 2013

US. Patent

oor Z-HZ ‘Old

US 8,489,224 B2

Sheet 48 of 61

Jul. 16, 2013

US. Patent

L-I@ “Old

US 8,489,224 B2

Sheet 49 of 61

Jul. 16, 2013

US. Patent

oor” Z-Iz “Old

US 8,489,224 B2

Sheet 50 of 61

Jul. 16, 2013

US. Patent

l-fe “Old

US. Patent Sul. 16, 2013 Sheet 51 of 61 US 8,489,224 B2

400

ae

FIG. 2J-2

US. Patent Sul. 16, 2013 Sheet 52 of 61 US 8,489,224 B2

FIG. 2K-1

US 8,489,224 B2

Sheet 53 of 61

Jul. 16, 2013

US. Patent

Gop Z-NZ “Old

US. Patent Sul. 16, 2013 Sheet 54 of 61 US 8,489,224 B2

FIG. 2L-1

US. Patent Sul. 16, 2013 Sheet 55 of 61 US 8,489,224 B2

400

ae

FIG. 2L-2

US 8,489,224 B2

Sheet 56 of 61

Jul. 16, 2013

US. Patent

Ca) Gans) Games aay

yop Bunn ynd}n0

eS

SONS OOO

© 96re lI

es

a1 99KS “7 wadsp 303/95 “1

suonipuosf6un3no Aupoyis

aa

ayoyduoy euibu uoyp.ed9

siojouniod “9s1N >)

uae

Abyouy>al ps|

pro2wy, ABjouypay

sien}

feo

Aajausoag @-

fa uBnoy!

eu,

D>

acs)

TonoIsdObUIION

ve ‘Old

US 8,489,224 B2

Sheet 57 of 61

Jul. 16, 2013

US. Patent

Cp000 J

(02) (wm) vo

(vow) v9)

(mooy/usu) 74

“(uruu/ us)

UBIO jonjyay@

yp Bunyng yndyng-

e

ByDIAUAG |] (SIMD] W 20s) (_ AOS)

cops 000 ve)

ooo 96re' ei]

000% _s+z#6|

ees Sov uydeg

pao] 49186 wdap 399795 “|

suonipuoa Burin Apo suoripuos Bun yn9

2e

ayoiduro,

suojaupiod -261y1 >

wae

Abjouysoy gas

puozm, ABjouyoo) 64

spot FY

too GB

Anouiosg G+

ubrow

TEEN

UwonDiedgbUIUNyDOR

ag “Old

US 8,489,224 B2

Sheet 58 of 61

Jul. 16, 2013

US. Patent

P1BuI9@

yop Bur

ey

fayOITOIOD ® BA0S) (OAS }

fesiee coon ve

coors o6veeiL)

eussepOHy

Fpno yo1as “7

000% _avzv'6[)

Sddv| sndeg

udap y09I95 "1

suorypuoa Suny

2B

ayodw9y

n> fypon|fsuorypuo> Sugino

‘ouiDu_wonDzadg

suoyouns0d “351W

punzy\ Bjouypay

spre

eo, GE

Anjousoeg @-!

BOUL

wonoredgSumiyo0"

o¢ “Old

US 8,489,224 B2

Sheet 59 of 61

Jul. 16, 2013

US. Patent

(ido an09)

Cae) ams) GRR aS

sovee ooo vePy

ooo s6ve'81L]

oz _aver'6L]

Sd0¥)

og

ayoydwoy,

‘uibu uojosedg

sejauoind “291n

ur

Abjouypay

puoziy, K6jouyo0y

spna)

reo,

kxyaunag >!

now

OUTS,

oRDISdQBUNIDON

d¢e ‘old

US 8,489,224 B2

1

COMPUTERIZED TOOL PATH GENERATION

FIELD OF THE INVENTION

‘The present invention relates to systems and methodolo- 5

tes for automated tool path design and computer controlled

machining and prouts produced hereby

BACKGROUND OF THE INVENTION

»

‘The following publications are believed to represent the

‘eurrea sate ofthe at an ae hereby inconporated by refere

US, Pat, Nos. 4,745,588; 4,907,164; 5,363,308; 6.363,

208; 6.447.223; 6,591,158; 7451, 013; 7.577490 and 7.831

33%; and

US Published Patent Application No,: 200510256004.

‘SUMMARY OF THE INVENTION

‘The present invention seks to provide systems an meth-

‘odologies for automated toa ath design and computer coa-

trolled machining and procs rodced thereby.

‘There is thus provided in accordance with 2 prefered

«embodlimentof the present invention anawtomated computer

implemented method for generating commands foe coneol

ling computer numerically controled machine o fabricate

abject froma workpiece the method inching the steps oF

selecting maximum permitted engagement angle berween.a

rotating outing to! an the workpiece selecting «minimum

permifted engagement angle between the rating eating 0]

and the workpiece, and configuring a tool path forthe tol

relative tothe workpice in which the cgagement angle

tnadully varies beteen the maximum permite engaae-

tment angle and the minimum permited engagement angle. 5

Tnaccorlance witha prefered embedment ofthe present

invention, rspoasive to consideration of at lea one a eae

dcteristis of the computer merical controlled machine,

rotating cutting tool and material of the woekpoce the con:

figuring also includes minimizing, subjet 10 other con

straints, therate ofchangeo! the engagement angle over tine,

‘radully changing the feed speedo the tool comesponding

tothe changing engagement angle, msntining a generally

‘constant workload om the tool, and minimizing the cost of

fabricating the object, whereby he cost isa combination of 45

the cost of operating the machine forthe uration of the

fabrication andthe ostof the wear initeon the too during

the fabrication

Preferably, the tool path includes a plurality of tol path

segments and configuring a to! path ineides recursively

configuring each of the tol path seymeats, and wherein,

responsive tocoasidention fal eastoneafchareterisiesof

the computer numerically controlled machine, rotting ct

ting tool and materi of the workpiece, configuring each of

the tool path seymeats als eludes minimizing, subjet to

‘other constins the rate of change ofthe engagement angle

‘overtime, gradually changing the feed spood of the tol

‘corresponding to the changing engagement angle, meintain-

ing a generally consant work lod onthe tol, nd asinine

ing the cost of machining the each ofthe tool path seamen,

‘whereby’ the cost ia combination of the cost of operting the

racine foe the duration ofthe machining andthe cst the

‘wea inlited onthe too ding the machining

Aakitionally each of the tool path segments inches

plurality af too path subsegmeats and recursively eontig-

dng each of the tol path segments inches ecusively con-

figuring cach of the tool path subsegments, and wherein

»

2

responsiveto consideration ofa east one of characteristics of

the computer numerically coutlled machine, rotating eut-

ting tool and material ofthe workpiece, the configuring each

ofthe to! pat subsepments alsa incldes minimizing, sub-

ject olbercastrains, the rate of change ofthe engagement

angle overtime, gradually changing the feed specd of the tol

corresponding the changing engagement angle, maintain-

nga generally constant work lod on the too, and minimiz«

ing the cost of machining the each of the tool path subsea

ments, whereby the cost is a combination of the cost of

operating the machine forthe duration ofthe machining and

the costo the wear inficteon the tool during the machiaing,

‘There is also provided in accordance with another pre

ferred embodiment of the present invention # method! for

machining a workpiece employing a computer conteolled

‘machine too, the method including directing the too along 8

‘ool path wherein an engagement angle between the too ad

the workpioce gradually varies between a preselocted maxi-

rium permited engagement angle and a preselected mini-

mum pemnited engagement angle.

‘There is further provided in accordance with yet another

prefered embodiment ofthe resent invention an automated

computerimplemented apparatus for generating commands

Jor cootrling a computer numerical conmlled machine to

Jabricatean object froma workpiece, the apparatus including

«tool path configuration engine operative Toe configuring 8

tool path for a tool relative tothe workpiece ia whieh the

engagement angle gradually varies between a preselected

raximum permitted engagement angle and a preselected

rminimum permitted engagement angle.

Preferably the configuring includes minimizing, subjetto

other constraints, the rate of change ofthe engagement angle

overtime, Preferably, te configuring also includes gradually

caging the feed speod of the tol coreesponding © the

changing engagement angle. Preferably, the configuring is

also operative to maintain a generally constant workload on

the tool, Preferably, the configuring is also operative to mini=

mize the cost of fabricating the object, whereby the cost is 2

combination of the cost of operating the machine forthe

uration ofthe fabricationand the cost ofthe wea iflictedon

the tool during the fabrication, The prefered features refer-

enced in this paragraph are also applicable to all appropriate

claimed embodiments of the present invention.

Preferably, te tol path includes plurality of too! path

segments and configuring a tool path includes recursively

configuring exch of the tool path segments, and wherein the

configuring each of the tool path segments also includes

‘minimizing, subject o other consists, the ateof change of

the engagement angle overtime, gradually changing the feed

speed ofthe tool corresponding tothe changing engagement

angle, maintaining a generally coustat workload onthe oo,

snd minimizing the costof machining theeachof te tol path

segments, whereby the cost is a combination of the cost of

operating the machine forthe duration ofthe machining ae

the cost ofthe wear inflicted onthe ool during the machining

The preferred features refereed inthis paragraph are also

applicable to all appropriate clsimed embodiments of the

present invention,

Preferably, each ofthe too! path segments includes a plu-

rity of too! path subsegments and recursively configuring

exch ofthe foo path segments incdes recursively configt=

Jing each ofthe tol path subsepments, and wherein the con-

figuring eachof the oo! path subsegments als includes mini-

nizing, subject to other constrains, the rato of change ofthe

engagement angle overtime, gradually changing the feed

speed ofthe tool corresponding othe changing engagement

angle, maintaining a generally constant workload onthe oo,

US 8,489,224 B2

3

and minimizing the cost of machining the each ofthe too pa

subsegments, whereby the cost isa combination of theeost of

‘operating the machine for the duration ofthe machining and

the costo the wea nficteon the tool during the machining,

‘The proferred features reference in this paragraph ae also

applicable to all appropriate claimed embodiments of the

preset invention,

Preferably, the configuring also includes considering at

least one of characteristics ofthe computer numerically con

trolled machine, rotating cutting tool and material of the

workpiece. The prefered feutues referenced in this para

_araph are also applicable wall appropriate claimed embod

ments ofthe present invention,

“There is yet further provided in acconlance with still

‘another prefered embodiment of the present inveation an

sutomated computer-controlled machine w fabricate an

‘object from a workpiece, the machine inchuding a conrller

‘operative for dtectinga rotating cutting tol along a too path

relative to the workpiece in Which an engagement angle 2

between the tol and the workpiece gradually varies between

‘preselected maximum permitted engagement angle and a

preselected minimum permitted engagement angle

‘There is yet further provided in accordance with still

another prefered embodiment of the present invention an

‘object fabricated from a workpiece machined using a com-

puter controlled machine tol by directing 2 ating cuting

‘ool along too! path wherein an engagement angle between

the rotating euting tool and the workpiece gradually varies

between a preselected maximum permitted engagement

angle and « preselected minimum permitted engagement

angle

‘There is yet frther provided in accordance with sill

nother prefered embodimeat of the resent invention an

tuomated computerimplemented method for generating

‘commands for controlling a computer numerical contolled

machine to fabricate an object from a workpiece the method

including he stepsof selecting a regionot the workpiece tobe

removed by a rotating cuting tol, configuring an asymmet-

rie spiral to! path forthe rotating cutting tol inthe epion of

the workpiece, which asymmetric spiral ool path maximizes

the portion of the region of the workpiece which is removed

by the roating cutng tool moving along the asymmetric

spiral tool path.

Preferably, the method also includes configuring at least

‘one trochoidal-lik tool path forthe rotating cutting too in a

remaining portion ofthe region of the workpiece which is,

remuved by the tool moving along the tochoidal-lke tol

path

Preferably, the method also includes selecting maximum

permitted engagement angle between a rotating cutting tol

and the workpiece, selecting a minimum permited engage-

rent angle between the rotating cutting tool and the work

Piece, ane configuring the asymmetric spiral to! path an the

atleast one tochoidal-like tol path relative w the workpivce

so thatthe engagement angle gradually varies between the

maximom permitted engagement angle and the minimm.

permitted engagement ange

Preferably, responsive to consideration of atleast one of

‘characterises of the computer numerically controlled

‘machine, rotating cutting ool and material ofthe workpiece,

the configuring also includes minimizing, subject to other

‘constraints, the rate of change of the engagement angle over

time, gradually changing the feed speed ofthe tool core

sponding to the changing engagement angle, maintaining

generally constant work ladon the tool, and minimizing the

‘costo fabricating the objet, whereby the cost sa combina

4

tion ofthe cost of operating the machine for the duration of

the fabrication ad the cost of the wear inficted on th tol

during the fabrication

Preteably, the asymmetric spiral too! path includes a plu-

‘ality of spizl tol path segments, deat east one rochoidal-

like tool path includes a plurality of trochoial-tike tool path

segments, configuring an asymmetric spiral tool path

includes reeusively configuring each ofthe spital ool path

segments, and configuring atleast one tveboidal-like tol

path includes recursively configuring each ofthe rochoidal-

like tool pth segments, and wherein responsive to consider-

ation of atleast one of characteristics of thecomputer mumeti-

cally controlled machine, rotating cutting foo] and materia of

the workpiece, the configuring each ofthe tool path segments

also includes minimizing, subjectto other constraints, the rate

of change of the engagement angle over time, gradually

changing the feed speed of the tool corresponding t the

changing engagement angle, mriatsining a generally coa-

staat work load on the tool, and minimizing the cost of

machining the each of the tool path sepmients, whereby the

cost isa combination ofthe ost of operating the machine for

the duration of the machining and the cost of the wear

inflicted onthe tool during the machining.

Additionally, each of the too! path segments includes a

plurality of tool path subsegments and recursively configure

‘ng each ofthe tol path segments includes recursively con

figuring each of the tool path subsegments, and wherein

responsiveto consideration ofat eat oneof characterises of

the computer anmerically controlled machine, rotating cut-

ting tool and material ofthe workpiece, the configuring each

‘ofthe tol path subsegments also includes minimizing, sub-

jc other constrains, theate of ehange of the engagement

angle over timo, gradually changing the feod speed of the tol

corresponding 1 the changing engagement angle, maintain-

ing a generally constant work load on the tool and minimiz=

Jing the cost of machining the each of the tool path subsea

ments, whereby the cost is a combination of the cost of

operating the machine forthe duration ofthe machining and

ttecost of the wear inflicted onthe tool during the machining,

Preferably, the asymmetric spiral too! path is one of @

coaverging spiral tool path and a diverging spiral tool path

“There is Yet further provided ia accordance with still

another prefered embodiment of the present invention a

method for machining a workpiece employing a computer

controlled machine tool, the method including selecting a

region ofthe workpiece to he removed by a oating cutting

tool, and directing the too! along an asymmetie spiral tol

path inthe region ofthe workpiece, wherein the asynmeteic

spiral tol path maximizes the portion ofthe region of the

‘workpiece whichis removed by the roating cutting tool mov-

ing along the asymmetic spiral too path. Preferably, the

method aso includes divcting the eating etting oo! along

st eat one trochoidal-like ool path in remaining portion of

the region of the workpiece which is removed By the tol

‘moving along the tochoidal-like tool path,

“There is yet further provided ia accordance with still

nother prefered embodiment of the present invention an

suomated computerimplemented apparatus for generating

commands for eonvoliag a computer numerical conlled

chine to fabricate an objet from a workpicce the appara-

tus including a tool path configuration engine operative for

selecting a region of the workpiece to be removed by a rtat-

ing cuting oo, atl for configuring an asyaunetric spiral tol

path forthe rotating cutting tol in the region of the work

piece, which spiral to! path maximizes the portion ofthe

regioa ofthe Workpiece which is ramoved by the rotating

cutting too! moving along the asymmetric spiral ool path

US 8,489,224 B2

5

Preferably, the ool path configuration engine isalso opera-

tive for configuring at least one tochoidal-like tool path for

‘heotating cutting ool ina remaining porionof theregion of

‘he workpiece whichis removed by theo moving slong the

twochoidallike tool path s

Preferably, the configuring includes selecting « maximum

permitted engagement angle between a rotating cutting to!

and the workpiece, selecting 2 minimum permited engage-

meat angle between the rotating cutting tool and the work

Piece, and configuring the asymmetric spiral tol path andthe

atleast one trochoidal-like tol path relative tthe workpiece

so thatthe engagement angle gradually varies between the

‘maximum permitted engagement angle and the minimum

permitted engagement ange.

Preferably, the configuring includes minimizing, subjetto 18

‘other constrains, the rae of change ofthe engagement angle

‘overtime. Preferably, the configuring also includes gradually

‘changing the feed spoed ofthe tool coresponding to the

‘changing engagement angle. Preferably, the configuring is

also operative to maintain a generally constant work load on

the too. Preferably, the configuring is also operative to mini-

mize the cost of fabricating the object, whereby the cost is a

‘combination ofthe cost of operating the machine for the

‘duration ofthe fabrication andthe cost ofthe wearinited on

the to! during the fabreation

Preferably, the asymmetric spiral tool path includes a pla-

rally of spiral tool path segments, thea eat one tochoidal=

like tol path includes a plurality of rochoidal-tike tool path

segments, configuring an asymmetric spiral tool. path

includes recursively configuring each of the spiral tool path

segments, and configuring atleast one trochoidal-hike tol

Path includes recursively configuring each ofthe trochoidal-

like tol path segments, and wherein responsive to coasidee-

ation atleast one of characteristics ofthe computer umeri-

‘aly conitolled machine, rotating cutting tool and material oF

the workpiece, the configuring each ofthe too! path sepments

‘als includes minimizing, subject other constraints therate

‘of change of the engagement angle over time, gradually

‘changing the feed speed ofthe tool coresponding to the

‘changing engagement angle, maintaining a generally con-

sant work lood on the tool, and minimizing the ost of

machining the each of the tol path segments, whereby the

‘cost isa combination of the cost of operating the machine for

the duration of the machining and the cost of the Wear

inflicted onthe tool during the machining

Additionally, exch of the tool path segments inches a

plurality of tool path subsegments and recursively configur-

ing cach ofthe tol path segments includes recursively

figuring cach of the tool path subsegments, and wherein

responsive oconsideration ofa least one of characteristics of Sb

the computer numerically controlled machine, rotating cut-

ting tool and material ofthe workpiece, the configuring each

‘of the tool path subsegments aso ineludes minimizing, sub-

{oct toother constraints, the rateof change ofthe engagement

‘angle overtime, gradually changing te fed speed ofthe tool

‘corresponding tothe changing engagement angle, mina

ing a generally constant work load on the too, snd minimiz~

ing the cost of machining the each af the tol path subseg-

meats, whereby the cost is a combination of the cost of

‘operating the machine for the duration ofthe machining and

the cost ofthe wear infliction the tool during the machining,

Preferably, the asymmetric spiral tool pah is one of a

‘converging spiral tool path anda diverging spiral tol path

‘There is yet further provided in accordance with still

another prefered embodiment of the present invention an

‘aufomsted computer-contolled machine 10 fabricate an

‘object from a workpiece, the machine including a controller

Fa

6

operative for selecting 4 region of the woskpiese 10 be

removed by a rotating cutting tool, and for directing the

rotating cting tool along an asymmetric sia ol psi in

theregion ofthe workpiece which pra tool path maximizes

the portion ofthe region ofthe workpiece which is removed

by the rotting cutting tool moving along the asymmetric

spiral oo path

Preferably, thecontlleris ls operative for directing the

rotating cuting ool alg atleast one tochoidal-ke ool

path in a remaining portion ofthe region of the workpiece

Thich s removed by the tol moving along the tochoidl-

like too path

‘There is yet further provided in aecondance with sil

another preferred embodiment ofthe present invention an

objet fabricated rom a workpiece machined using & com-

per controlled machine tol by selecting a region ofthe

workpiece to be removed bya rating eutng tol and by

dzeting the rotating ctting tol slong an asymmetec sical

‘ool path athe region ofthe woekpgee, which pital too path

maximizsthe portion ofthe regina the workpiece whichis

removed bythe eating eutng tol moving along the asym-

rote spiral tool path

Prelerably, the objet i ibicated also by dieting the

rotting cuting tool along at ess one tehodl-ke tol

path in a remaining portion ofthe region of the workpiece

Thich is removed by the tol moving along the tochoidl-

ike tol path

‘There is yet furer provided in aecordance with sll

anoher preferred embodiment ofthe present invention an

automated computerimplemented method for generating

commands for conioling a computer numeral eontlled

machine to farcatean object froma workpiece the mth

inclodingthe stops of selotingareaionof the werkpieceto be

removed bya mating euting oa, selecting it portion of

the eon o be removed by an asymmetric spiral oo pa

and configuring at fast one tochoidal ike tol path for

removing a reniaing portion ofthe eon, and wherein the

selecting aft potion ofthe region is operative a minimize

the machining ime necessary o remove the region.

Prelerably ibe method also includes selecting maximum

permitted eagagement angle between a tol and the work-

Piece, selecting minimum permited engagement angle

between the tool and the workpiece, and configuring the

asymmiete spiral ool path and the at lest one tochoidl-

ike oo! pathrelatveto the workpiece so that the engagement

angle gradually varies hetween the maximum permited

engagement angle and he minimum permitted engagement

angle

Preferably, responsive to comidertion ofa least one of

characterises of the computer numerically. contalled

nuachine rotating euting ool and materia of the workpiece,

the configuring also includes nizing, subjet to other

constraints, the rate of change ofthe engagement angle over

time, gradually changing the fed spe of the tool core-

sponding to the changing engagement angle, maining a

severly constant work oad onthe tol and minimizing the

ost avicatng te object, whereby the ost isa eombina-

tion athe cost of operating the machine forthe duration of

the fabrication an the cst ofthe wear ilictd onthe tool

during the fabrication,

Preferably the asymmetric spiral tol path ina plo-

salty of spiral ol pth seement, the ateast one wochoidal-

like to! path aces plurality of tochoida keto! path

segmens, the configuring an asymmetric spiral tool path

inches recursively configuring each ofthe spiral ool pth

Segments, the configuring at least one tochoidal-ike tol

Path incades recursively configuring each of the ochoidl-

US 8,489,224 B2

1

like tol path segments. and wherein responsive to consider-

ation ofa leastoneof characteristics ofthe computer numeri

‘ally controled machine, rotating cuting tool nd material of

the workpiece, the configuring each of the tool path segments

‘also includes minimizing subject olher constants therate

‘of change of the engagement angle over time, gradually

‘changing the feed speed ofthe tool coresponding to the

changing engagemeat angle, maintaining 2 generally oon-

stant work od on the tool, and minimizing the ost of

machining the each of the tool path seaments, wliereby the

‘cost isa combination of the cost of operating the mache for

the duration of the machining and the cost of the Wear

inflicted onthe tool during the machining

Preferably, ese of the tool path segments includes plu

ralityof too! path subsegments and recursively configuring

‘each ofthe tool path segments includes recursively contigue-

ing each ofthe ool path subseyments, and wherein respon

sive to consideration of at last one of characteristics ofthe

‘computer numerically controlled machine, rotating cutting

‘ooland material ofthe workpiece, theconfiguringeachofthe 2

tool path subsegments also eludes minimizing, subject to

‘other constraints, the rate of change ofthe engagement angle

‘overtime, gradtlly changing the feed spood of the tol

‘soresponing tothe changing engagement ange, msintsin-

inga generally constant work lod on the oo, and minim

ing te cost of machining the cach of the tol path subsea

meals, whereby the cost is combination of he cost of

‘operating the machine forthe dation ofthe machining and

thecostof the wea infictdon the tol during te mschining.

Preferably, the asymmetric spiral tol pth is one of a

‘converging spiral ol path ae averging spiral ol path,

‘There is yet farber provided in accordance with tl

swothor prefer embodiment of the preset inveation a

method for machining 8 workpiece employing a computer

come michine to, the metbod inclding slong @

region of the workpiece to be removed by aotatngeuting

tool selecting fit potion of the repion o be removed by

asymmetric spiral ool pa, and directing the tol along at

least one trochoidablike too! pth in a remaining portion of

the region ofthe workpiece, and wherein selecting fist

postion ofthe region sapeatve to minimize the machining

Hime necessary to remove the region

‘There is yet fariber provided in accordance with stl

nother prefered embodiment of the preset vention an

‘ome computer implemented appérats fo generating,

‘commands for contin a computer numerical eontoled

machin o fabricate an objet fom a workpiece, the apara-

tus inluding tool path configuration engine operative for

selecting region of the workpieeto be removed bya rate

ing cutting tol, olectinga fst potion ofthe region to be

removed by an asymmetric spiral ol a and for configu

ing atleast one tobaial-tike tool path for removing @

remaining potion of th region, and wherein the selecting 2

fistporionof the region isoperativeto minimize the machin

ing ine necessary to remove the region.

Preferably the config ncdes selsing a mai

permitted engagement angle between rating eting tol

andthe workpiece, selecting a minimum pemiteengage-

meat angle between the rotating euting ool and the Work

piece, and configuring the asymmetric sil tool pathandthe

atleast onetrochoidel-ike tol pa elatve tothe workpiece

fo tat the engagement angle gradually varies berween the

maximum permitted engagemeat angle and the misimm

permite engagement angle

Preferably te configuring includes minimizing, sbjet io

‘other constrains the rate of change ofthe engagement angle

‘overtime. Preferably the configuring also includes radly

s

8

changing the fed speed ofthe ool corresponding wo the

changing engagemeat angle Prefebly, the configuring is

als operative to maintain generally constant work load on

the oo, Prefebly, the configuring also operative omni

mize the cost of abicating the objet, whereby the cost isa

combination of te cost of operating the mache forthe

duration ofthe fabicationandthecost ofthe wear infictd on

the tool daring the fibration

Preferably the asymmetric spiral tol path inhadesaplo-

salty of spiral tool pth seamen that east one tocboidal-

like to! path aces plurality of troche tol path

segments, configuring an asymmetric spiral tol path

inches recursively configuring each of the spiral Yo! path

Seqncus and configuring atleast one trochoidal-ike tool

put includes recursively configuring each ofthe woshoidl-

ike tool pth segneats, and wherein responsive wo consier-

ation fat estone of characteristics the compte mumed-

cally controled machine, ating cuting tol and material of

the workpieve th configuring each othe oo pat segments

alsoincudes minimizing, subjectto other constants theate

of change ofthe engagement angle over time, gradually

changing the fed speed ofthe tool comesponding. to the

changing engsgemet ange, minting @ genealy con-

stant work foad on the tol, and. minimizing the cost of

machining the exch of the tol path segment, whereby the

costiva combination ofthe cost of opening the mache for

the duration of the machining and the cost of the Wear

inflicted on the to! during the machining

Ationally, each of the tol path seymens includes a

plurality of tool path ubseyments and recursively contig

dng each ofthe too path segments includes recursively con-

figuring each ofthe tool path subsegments, and wherein

responsvetoconsidetionof at leastone ofchareteristiesof

the computer numerically controlled machine, rotating eu

ting tol and material ofthe workpiece, the coniguring each

ofthe tool path subscuments alsa inelides minimizing, sub-

ject other constrains, the rate of change ofthe engagement

angle overtime, gradually changing the feed speed of theo!

cortesponting (the changing engagement angle, maintan-

ings generally constant workload onthetool and asninizing

the cos of machining the each of the tool path subseamens

whereby the costs combination of the cost of operating the

racine forthe duration of the machining ad the cost ofthe

‘wer nlite onthe ool during the machining,

Preferably, the asymmetric spiral too! path is one of

conversing spi too path anda divering spiral tol pth

“There is yet fare provided ia secondance with sll

note prefered embodiment ofthe present invention an

automated computercontlled: machine to fabricate an

objet fom a workpiwe the machine inclu a conwoler

operative for selecting region of the woripieee to be

removed by a rottingeuting oo, selecting first portion oF

the region to be removed by an agymmetc spiral tol path

anu foe dreting the rotating euting too long atleast one

traci too! path inthe eo of the workpiece, ad

wherein the selecting a fist portion of the region is operative

to minimize the machining time necessary to remove the

region

“Thor is yet fare provided in aecordance with sill

nother preferred embodiment ofthe present invention an

object fabricated rom a workpiece machined using com-

puler controlled machine tol by selecting a region ofthe

‘workpiece to be removed by a oatngcuting tol slecting

frst potion ofthe ein to be emved by an asymmetric

spiral to! path andy directing he rotating eting ol along

at leat one tmhoida-ike tool pat in the region of the

US 8,489,224 B2

9

‘workpiece, and wherein the selecting a fst poston of the

regio s operative to minimize the machining time nevessary

to remove the region

There is yet further provided in accondance with still

‘another prefered embodiment of the present invention ans

automated computerimplemented method for generating

‘commands for controlling a computer numerical eontolled

‘machine o fabricate an object fom a workpiece by removing

portions ofthe workpiece which are aot o be included ia the

‘object, the method including the steps of considering the

‘ross section of a desired object to be fabricated from a

‘workpiece, defining isolated regions ofthe cross section on

the workpiece surface which ae not tobe removed as islands,

‘commencing configuring oF ool path in aregion not having

islands, and upon the to! path encountering an island, coa

figuring a moat tool path Which defines @ moat surounding

the island

Preferably the method also includes defining « composite

region inchiding the island, the moat surrounding the island

and regions already removed from the workpiece a a

removed region and configuring a tool path to remove a

remaining region ofthe workpiece, which remaining region

‘doesnot include the removed region,

Preferably, the method also includes selecting 2 maximum

permitted engagement angle between a tool and the work

piece, selecting minimmim permitted engagement angle

between the tol and the workpiece and configuring the moat

‘ool path relative w the workpiece so thatthe engagement

angle gradually varies between the maximum permitted

‘engagement angle and the minimum permitted engagement

angle.

Preferably, responsive to consideration of at last one of.

characteristics of the computer numerically contled

‘machine, rotating cuting tool and anateral ofthe workpiece,

the configuring also includes minimizing, subject wo other 35

‘constants, the rate of change of the engagement angle over

time, gradually changing the feed speed ofthe tol core

sponding o the changing engagement angle, maintaining &

eneraly constant work load on the tool and minimizing the

‘cost of fabricating the objet, whereby the costs combins-

tion of the cost of operating the machine fr the duration of

the fabrication aad the cost of the wear alice oa the tal

during the fabrication.

Adkiionlly the oo! paths inelude a plurality of too! path

segments and configuring the tool paths includes recursively

‘configuring each of the tool path segments, and wherein

responsive to consideration ofa eat oneof characterises of

the computer numerically conteolled machine, rotating eut-

ting tool and material ofthe workpiece, the configuring each

‘ofthe tool path segments also includes minimizing, subject. 50

‘other constrains, the rae of change of the engagement angle

‘over time, gradually changing the feed speed of the tool

‘corresponding tothe changing engagement angle, maintsin-

ing a generally constant work load on the tool, and minimiz~

ing the cos of machining the each of the too path segments,

whereby the cots combination ofthe cost of operating the

‘machine forthe duration ofthe machining andthe cos af the

‘wear inflicted on the tol during the machining.

‘Additionally, each of the too! path segments includes a

plurality of tool path subsegments and recursively config

ing each ofthe to! path sepmentsinchades recursively con

figuring each of the tool path subsegments, and wherein

responsive To consideration of at east one of characteristics of

the computer numerically controlled machine, rotating et

ting tool and marecal ofthe workpiece, the configuring each 6s

‘of the tool path subsegments aso includes minimizing. sub-

Jesttootherconsrants, the rateof change ofthe engagement

10

angle overtime, gradually changing the feed speed of theo]

corresponding to the changing engagemest angle, msintain-

inga generally constant work ad on te tol, nd minimiz-

ing the cast of machining the each of the tol path subsea

nnens, whereby the esti a combination of the east of

jperating the machine forthe duration of the machining and

thecostof the wea infietdon the tol during the machining.

There is yet further provided in scordance with st

anoiber peefered embodiment of the present invention a

mmetod for machining « workpiece employing «computer

controlled machine tel, the method inluding considering

the eros section of a desired objet to be fabricated fom a

vwrkpiee, defining isle regions ofthe cos section on

the workpiove surface which are motto beremaved as islands,

inally dieting the to! sng ato! path ina region not

having sland, and upon the tol path encountering anisland,

diretng the tol along moat oo path whichdefine moat

surrounding te island

There is yet further provided ia aocordance with sill

another prefered embodiment ofthe present invention an

automated computermplemented apparatus for generating

commands for controling a computer unsrialcontlled

machin o fabricate an object from a workpiece the appara

tus inluding too path configuration engine operative for

considering the coss Seton ofa desired objet to be fabe-

cated fom workpiece defining isolated epionso the cross

section on the workpiee surface which remot to Be emoved

as lands, commencing configuring of tot pat ina region

not having islands and upon the to! path encountering an

island for configuring a meat tool pth which defines a moat

surrounding the sland,

Preferably, the configuration engine is also operative for

defining a composite rpion inluding the island the moat

surmunidng the snd ad regions already removed fom the

‘workpieces removed reyion and foreonfgurngatoa path

to remove a remaining region of the workpiece, which

remaining region does not nce the removed region.

Preferably, the configuration engine is slso operative for

selecting amaximum permitted engagement ange between

tool and the workpiee, selecting, @ minimum permited

engagement angle between the ol aad the workpiece and for

onigriag the moat tol path relative othe workpiece so

thatthe engagement angle gradually varies between he maxi-

sum permite engagement angle and the mii peri

tod engagement anal,

Preferably, responsive to consideration of atleast one of

characterises of the computer numerically contlled

‘ache, rotting eating tol and material ofthe workpiece

the configuring also includes nizing, subjet to other

constants the rate of change of he engagement angle over

time, praualy changing the fed spe ofthe tool core-

sponding tothe changing eogagement angle, maintaining a

generally constant workload onthe tol and minimizing the

costa fahvicatng the abject, wherehy the cost isa combina

tion ofthe cost of operating the machine forthe duration of

the fabrication and the cost ofthe wear iaficted onthe tool

during he fabrication

‘Adtionally the to! paths incude a plurality of! path

segmenis and coniging ot pasincludesrecuaively Gon-

figuring each of th oo ath Segments, and wherein espon-

sive to consideration of at east ane of characteristics ofthe

computer numerically conelled machine eating eating

tooland material ofthe workpiece, the configuringeacho the

tool path segments also inehas minimizing, subject to thor

constraints, the rate of change ofthe engagement auale over

time, prualy changing the fed speed ofthe tool core-

sponding to the changing engagement angle, maintaining a

US 8,489,224 B2

generally constant work ladon the too, and minimizing the

‘costof machining the acho the tol path segments, whereby

thecostisa combination ofthe cost of perting the machine

forthe duration ofthe machining and the cost ofthe wear

inflicted on the to! dusiag the machining

Additionally, cach of the tool path segments inches a

plurality of too path subsegments and rvursively configu

ing each of the tool path segments inches ecusvely con-

figwing each ofthe tool path subseamens, and wherein

responsvetoconsiertion of aleastoneofchareterisies oF

the computer mumeially conolled machine, rotting cut

tng tool and mate ofthe workpgce the configuring each

‘ofthe tol pth subsegments lo incides minimizing, sub-

{stinother constants, the ratcof change ofthe engagement

‘angle ver time, rail changing the fee sped ofthe tol

‘onesponding (0 the changing engagement agle, maintain.

ing a generally constant workload onthe tol nd minimiz-

ing the cost af machining the cach of the tol path subsea

Ines, whereby the cost a combination of the cast of

‘operating the machine for the dation ofthe machining and

thecostof the wear infictedon the tol during the mechining.

“Thar is yet farther provided in accordance with sl

another peered embodiment ofthe presen vention an

automate! computer-

You might also like

- United States Patent Patent No.: US8 215,454 B2: Portlock Et Al 10) 45) Date of Patent Jul. 10, 2012No ratings yetUnited States Patent Patent No.: US8 215,454 B2: Portlock Et Al 10) 45) Date of Patent Jul. 10, 201213 pages

- United States Patent: (12) (10) Patent No.: US 7,109,625 B1No ratings yetUnited States Patent: (12) (10) Patent No.: US 7,109,625 B134 pages

- United States Patent (10) Patent No.: US 8,154,167 B2No ratings yetUnited States Patent (10) Patent No.: US 8,154,167 B226 pages

- United States Patent: Holtzapple Et Al. (45) Date of Patent: Feb. 16, 2010No ratings yetUnited States Patent: Holtzapple Et Al. (45) Date of Patent: Feb. 16, 201023 pages

- United States Patent: ( ) Notice: Subject To Any Disclaimer, The Term of This Is: A SE A. Et AlNo ratings yetUnited States Patent: ( ) Notice: Subject To Any Disclaimer, The Term of This Is: A SE A. Et Al30 pages

- Patent Application Publication (10) Pub. No.: US 2011/030972.6 A1No ratings yetPatent Application Publication (10) Pub. No.: US 2011/030972.6 A122 pages

- Baker Hole Opener Reamer Patent US7681666No ratings yetBaker Hole Opener Reamer Patent US768166650 pages

- US6435783 - Variable Radius Notching MachineNo ratings yetUS6435783 - Variable Radius Notching Machine48 pages

- Patent Application Publication (10) Pub. No.: US 2010/0127229 A1No ratings yetPatent Application Publication (10) Pub. No.: US 2010/0127229 A129 pages

- United States Patent: (76) Inventors: Kohei Minato, No. 901, 28-20, YotsuyaNo ratings yetUnited States Patent: (76) Inventors: Kohei Minato, No. 901, 28-20, Yotsuya24 pages

- Thermite Cristal Structure and Patent Related Documents For Extration of Thermite WeldingNo ratings yetThermite Cristal Structure and Patent Related Documents For Extration of Thermite Welding10 pages

- WILSON TOOL US8707841 Punch Assemblies and Universal Punch ThereforNo ratings yetWILSON TOOL US8707841 Punch Assemblies and Universal Punch Therefor61 pages

- United States Patent: Nood8D Patent Number: of Patent: Oct. 11, 1988No ratings yetUnited States Patent: Nood8D Patent Number: of Patent: Oct. 11, 198818 pages

- SSBBBBBBSAA 91778435241 64333309722 Oo, Oo, - /, - /,oo, - /,0,3, Oo, 30 797589977m% 33074636631 552,3,8,8,9,1,600 DD777778DWUNo ratings yetSSBBBBBBSAA 91778435241 64333309722 Oo, Oo, - /, - /,oo, - /,0,3, Oo, 30 797589977m% 33074636631 552,3,8,8,9,1,600 DD777778DWU8 pages

- United States Patent: Cheung Et A) - (45) Date of Patent: Oct. 30, 2007No ratings yetUnited States Patent: Cheung Et A) - (45) Date of Patent: Oct. 30, 200719 pages

- US8371840 Patent Document For Asb 70 DPHNo ratings yetUS8371840 Patent Document For Asb 70 DPH39 pages

- United States Patent: Roos (10) Patent N0.: (45) Date of PatentNo ratings yetUnited States Patent: Roos (10) Patent N0.: (45) Date of Patent20 pages

- Gas Turbine Engine With Resonator RingsNo ratings yetGas Turbine Engine With Resonator Rings10 pages

- United States Patent: (10) Patent No .: US 10, 396, 629 B1No ratings yetUnited States Patent: (10) Patent No .: US 10, 396, 629 B16 pages

- United States: (12) Patent Application Publication (10) Pub. No.: US 2009/0282723 A1No ratings yetUnited States: (12) Patent Application Publication (10) Pub. No.: US 2009/0282723 A118 pages