0% found this document useful (0 votes)

4K views14 pagesFDAS Interfacing

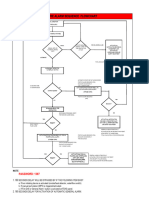

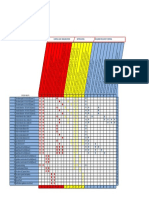

1. The document lists various fire detection and alarm systems that need to be interfaced with the FDAS, including smoke extraction systems, staircase pressurization systems, emergency lighting, and gas monitoring panels.

2. It provides information on the location and type of common FDAS devices to be used, including horn strobes, pull stations, modules for fire pumps and other equipment.

3. The zoning, monitoring and control functions of the FDAS are outlined, including pressurization fans, sprinkler flows, gas suppression panels and more. Phone jacks and devices are noted for various areas.

Uploaded by

Renzer NeznerCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

4K views14 pagesFDAS Interfacing

1. The document lists various fire detection and alarm systems that need to be interfaced with the FDAS, including smoke extraction systems, staircase pressurization systems, emergency lighting, and gas monitoring panels.

2. It provides information on the location and type of common FDAS devices to be used, including horn strobes, pull stations, modules for fire pumps and other equipment.

3. The zoning, monitoring and control functions of the FDAS are outlined, including pressurization fans, sprinkler flows, gas suppression panels and more. Phone jacks and devices are noted for various areas.

Uploaded by

Renzer NeznerCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

/ 14