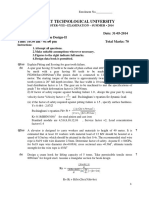

Total No. of Questions : 10] SEAT No.

:

P3745 [Total No. of Pages : 4

ic

[5561]-142

t

sta

B.E. (Mechanical )

:02

MACHANICAL SYSTEM DESIGN

:41

(2012 Course) (402048) (Semester-II)

/20 01

13

/05 85

Time : 3 Hours] [Max. Marks : 70

19

Instructions to the candidates:

1

1) Answer Q1 or Q2, Q3 or Q4, Q5 or Q6, Q7 or Q8, Q9 or Q10.

.98 N0

2) Neat diagrams must be drawn whenever necessary.

39 EG

3) Figures to the right side indicate full marks.

22

4) Assume suitable data, if necessary.

7.2 C

.47

ict

sta

Q1) a) A machine tool requires six speed gear box. Which having a 160 rpm

minimum and 1000 rpm maximum speed, when the motor shaft is

:02

1440 rpm. Draw the speed diagram for the following structural formula.

11

:41

01

i) 2 (3) 3 (1) ii) 2 (1) 3 (2). 13 [6]

85

19

b) Give formula for calculating Mean and Standard deviation of resultant

01

/20

Population if two individual populations are to be added and multiplied.[4]

/05

GN

OR

22

CE

.98

Q2) a) Draw the structure diagram and identify the optimum structural formula

.47

tic

out of them. i) 2 (1) 3 (2) ii) 2 (3) 3 (1) iii) 3 (2) 2 (1) [6] sta

39

7.2

b) Define design tolerance (DT) and natural tolerance (NT) in statistical

:02

design. State what happens when NT=DT, NT>DT and DT>NT. [4]

11

:41

01

13

85

19

01

/20

Q3) a) Explain the concepts of Unit Load and Containerzation. [4]

/05

GN

b) A three idler, troughed belt, horizontal conveyor is to be used for

22

transporting 500 ton of iron per hour having mass density of iron ore is

CE

.98

1700 kg/m3. If the belt speed is 2m/sec, determine the required belt

.47

width. Take surcharge factor = 0.1. [6]

39

7.2

OR

11

[5561]-142 1 P.T.O.

�Q4) a) State the appropriate guidelines for selection of material handling system.

[4]

ic

t

sta

b) A flat horizontal belt conveyor is to be used for transporting material

with mass density of 3 ton/m3. The belt is 750 mm wide and has speed

:02

of 2.75 m/s Determine capacity of vonveyor if surcharge angle is 25°

:41

/20 01

(k = 2.35 * 10-4). [6]

13

/05 85

19

.98 N0

1

Q5) a) Derive an expression for the thickness of a thick cylinder subjected to

internal pressure by using maximum shear stress theory. [8]

39 EG

22

b) A seamless cylinder with a storage capacity of 0.025 m3 is subjected to

7.2 C

an internal pressure of 20 MPa. The length of the cylinder is twice its

.47

ic

t

internal diameter. The cylinder is made of plain carbon steel 20C8

sta

( Sut = 390 N/mm2) and the factor of safety is 2.5. Determine the

:02

dimensions of the cylinder. [10]

11

:41

01

OR

13

85

19

01

/20

/05

GN

Q6) The following data refers to single acting hydraulic cylinder. [18]

22

Pressure of hydraulic fluid = 10 MPa

CE

.98

.47

tic

Operating force available at the piston rod. = 10KN sta

39

Friction due to piston ring and stuffing box = 10% of operating force

7.2

:02

11

:41

Thickness of cylinder flange = 10 mm

01

13

85

Thickness of cylinder head = 8 mm

19

01

/20

Cylinder and, cylinder head material = FG200

/05

GN

Modulus of elasticity for FG200 = 100 GPa

22

CE

.98

Thickness of Zinc gasket = 3 mm

.47

Modulus of elasticity for zinc = 83 GPa

39

7.2

Number of bolts =4

11

[5561]-142 2

� Preload in each bolt = 2.8 KN

Bolt material = FeE400

ic

t

sta

Modulus of elasticity for FeE400 = 207 GPa

:02

Factor of safety for cylinder =5

:41

/20 01

13

Factor of safety for bolts =6

/05 85

19

Standard diameter of cylinder

1 = 20, 30, 40, 50, 60 mm

.98 N0

Standard Thickness of cylinder = 2, 4, 5, 6, 7, 8, 10 mm

39 EG

22

Standard diameter of bolts = 8, 10, 12, 14, 16, 18, 20, 22 mm

7.2 C

Determine :

.47

ic

t

sta

i) Inner diameter of cylinder

:02

ii) Thickness of cylinder

11

:41

01

iii) Diameter of bolts

13

85

19

Q7) a) What is the difference between centre and overhung crankshafts? [6]

01

/20

b) The bore of a cylinder of the four stroke diesel engine is 120 mm. The

/05

GN

maximum gas pressure inside the cylinder is limited to 4 MPa. The cylinder

22

head is made of cast iron and the allowable tensile stress is 40 N/mm2.

CE

.98

Determine the thickness of the cylinder head. The studs which are made

.47

of steel have allowable stress as 50 N/mm2. Calculate i) Number of studs,

tic

ii) Nominal diameter, and iii) Pitch of studs. K = 0.162 [10]

sta

39

7.2

:02

OR

11

:41

01

Q8) The following data is given for a four- stroke diesel engine : [16]

13

85

19

Cylinder bore = 250 mm, Length of stroke = 300 mm, speed = 600 rpm

01

/20

Indicated mean effective pressure = 0.6 MPa., Mechanical efficiency = 80 %

Maximum gas pressure = 4 MPa

/05

GN

Fuel consumption = 0.25 kg per BP per hr.

22

Higher calorific value of fuel = 44000 KJ/kg

CE

.98

Assume that 5% of total heat developed in the cylinder is transmitted by the

.47

piston. The piston is made of gray C.I FG 200 (Sut = 200N/mm2 and

39

K = 46.6 W/m/°C) and the factor of safety is 5. The temperature difference

7.2

between the center and the edge of the piston head is 220°C.

11

[5561]-142 3

� i) Determine the thickness of piston head by strength consideration and

thermal consideration.

tic

sta

ii) State whether the ribs are required, If so calculate the number and

thickness of ribs.

:02

:41

/20 01

iii) State whether a cup is required in the top of piston head, If so calculate

13

the radius of the cup.

/05 85

19

Q9) a)

1

Write a short note on design for manufacturing and assembly.

.98 N0

[6]

b) A tensile bar of length 300 mm is subjected to constant tensile force of

39 EG

22

4 KN. If the factor of safety is 1.5, design the bar diameter, using

Johnson’s method with the objective of minimizing material weight using

7.2 C

optimum material from the list given below. [10]

.47

ict

sta

Material Density( ) kg/m3 Cost(c)Rs/Kg Syt N/mm2

:02

Steel 7800 34 400

11

:41

Aluminum alloy 2800 160 150

01

Titanium alloy 4500 2400 800

13

85

19

OR

01

/20

/05

GN

Q10)a) A tensile bar of length 400 mm is subjected to the tensile force of

4.5 KN. Assume Factor of Safety 2. Design the bar with the objective of

22

minimizing the material cost, out of the following materials: [10]

CE

.98

.47

tic

Material Mass Density Material cost Yield Strengthsta

39

kg/m3 per Unit Mass Syt N/mm2

7.2

c,Rs./kg

:02

Plain Carbon Steel 7500 16 130

11

:41

01

Aluminum Alloy 3000 32 50

13

Titanium Alloy 4800 480 90

85

19

Magnesium Alloy 2100 32 20

01

/20

b) Explain design consideration in design for forgings. [6]

/05

GN

22

CE

.98

.47

39

7.2

11

[5561]-142 4