0% found this document useful (1 vote)

805 views7 pagesConcrete Material Estimation Guide

To estimate materials for reinforced concrete (RCC) work:

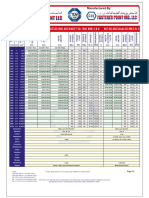

- For 1m3 of 1:1.5:3 concrete mix, estimate is 8 bags of cement, 0.42m3 of sand, 0.84m3 of aggregate.

- Reinforcement is estimated at 2.5% of volume for columns, equaling 196.25kg of steel for 1m3.

- Labor requirements are estimated based on standard schedules, such as 0.37 days for a mason.

- Equipment, sundries, and contractor profit are estimated as percentages of total material and labor costs.

Uploaded by

TanvirCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (1 vote)

805 views7 pagesConcrete Material Estimation Guide

To estimate materials for reinforced concrete (RCC) work:

- For 1m3 of 1:1.5:3 concrete mix, estimate is 8 bags of cement, 0.42m3 of sand, 0.84m3 of aggregate.

- Reinforcement is estimated at 2.5% of volume for columns, equaling 196.25kg of steel for 1m3.

- Labor requirements are estimated based on standard schedules, such as 0.37 days for a mason.

- Equipment, sundries, and contractor profit are estimated as percentages of total material and labor costs.

Uploaded by

TanvirCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 7