0% found this document useful (0 votes)

113 views32 pagesAc General Control System Doppler

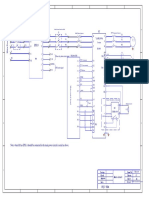

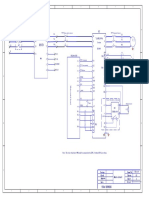

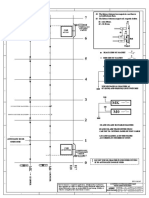

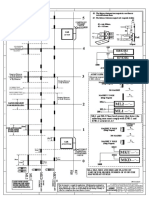

The document describes the specifications of the AC Series lift controller systems from AYBEY Elektronik. The controllers support up to 64 floors, CAN-bus communication, distance-based motion control, access security features, priority call systems, remote monitoring over internet/LAN, and comply with relevant lift safety standards. They can control electric or hydraulic lifts operating as single units or in groups.

Uploaded by

oro plataCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

113 views32 pagesAc General Control System Doppler

The document describes the specifications of the AC Series lift controller systems from AYBEY Elektronik. The controllers support up to 64 floors, CAN-bus communication, distance-based motion control, access security features, priority call systems, remote monitoring over internet/LAN, and comply with relevant lift safety standards. They can control electric or hydraulic lifts operating as single units or in groups.

Uploaded by

oro plataCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 32