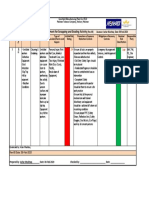

M/s:-

HCU & LOBS REVAMP PROJECT,

BPCL Refinery, MUMBAI

JOB SAFETY ANALYSIS FOR

PUMP INSTALLATION IN TS3 AREA

OWNER MAIN CONTRACTOR PMC

BPCL M/S SHILPI ENGINEERING PVT TECHNIP INDIA LTD.

REFINERY, MUMBAI LTD

0 Mr. ABIN Mr. SUDHI P Mr. BIPIN V

JOSEPH

Rev Date Prepared By Checked By Reviewed By Reviewed By Approved By

(Site Engr. (HSE, (RCM, (TPIL Engr.,) (BPCL)

Contractor) Contractor) Contractor)

JOB NO Date:

JOB Location : LOBS JSA No.: OIL\JSA-04

P&M and Hydra, crane, Web sling, Rev. No.: 000

Equipment, Tools & Rope, Bow-shackle, rechad,

Page | 1

� tackles involved chain pully block, lifting tools,

grinding m/c, ......................

Job Description: Prepared By: Mr.

(Contractor Site

Eng. Sup)

Job Classification: Pump Installation in TS3 Reviewed By: Mr.

Area. (Contractor HSE)

Name of the Site Approved By: Mr.

Mr.

Engineer: -M/s (Contractor

(contractor). RCM/Site

Manager)

PPE's / safety Status. Issued for

Safety helmet, Safety shoe,

device required implementation

Safety goggle, hand gloves.

/ review

No Task Step Hazards Recommended Measures

Job: Pump Installation in TS3

1 Preparednes Unawareness Permit should be obtained before starting of work.

s Untrained Common & Job specific induction will be done.

Trained & competent person will be deployed at

Page | 2

� job.

Inspection of area will be done prior to

commencement of job.

Hazards associated with sounding area and job will

be discussed with execution team.

2 Placement of Stuck or toppling Medically fit, Experienced, trained & competent

F15/Crane. Collide. operators will only be deployed on job.

Personal injury. Crain will be inspected by third party and valid

certificate will be available with Crain.

Crain operator will inspect Crain before placing and

operating daily & fill daily inspection checklist.

Daily checklist will be available with Crain.

Area should be visited for free movement & clear

workspace prior to place the equipment.

Compaction & proper level of ground will be

assured.

Flag man with red and green flag will guide

movement of equipment.

Job supervisor will ensure that vehicle shall be

provided with spark arrester & reverse horn.

3 Lifting & Fall of material. lifting tools & tackles with valid TPI certificate and

Shifting of Rigging failure. tagged by BPCL will be used.

Pump at job Toppling of Crain Physical inspection of lifting tools & tackles will be

Personal injury. done prior to commencement of job.

location. If heavy lift, then lifting plan should be made and

Weather

condition. job will be executed as per lifting plan.

Fall of person Job specific TBT will be given by job supervisor to

from height. execution team including Crain & truck operator &

helper.

Daily inspection of Crane will be done by operator

as per daily checklist.

Only trained & competent riggers will be deployed

for job.

Job supervisor will assure that Load should not

excess safe load limit in any case. Selection of

lifting tools & tackles will be done as per load.

Crane surrounding area will be properly barricaded

and caution boards should be placed. No

unauthorized person will enter inside barricade.

No free fall or jerk while lifting load.

No one should stand under suspended load.

Never bypass safety/Cutoff switches while lifting.

The Crane shall not be overload beyond it’s

carrying capacity.

No panels lifting/shifting will be done during rain or

height wind velocity.

If unprotected (without handrail) platform either

permanent or temporary no one will approach on it

without safety harness.

Lifeline will be installed on unprotected platform on

recommended height.

Job supervisor will ensure that all person working

on unprotected platform must anchor their harness

with lifeline.

Page | 3

� Panel will be controlled by guide rope if any case

hanging load will be not control by hand.

In any case no one should lean on platform.

Panels will be not stagged/store on platform.

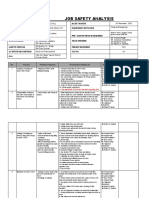

4 Placing of Fall of material. Experienced, trained & competent riggers should

Pump Unsafe placing of perform the materials handling & storing job.

Panels. Competency certificate will be kept in record.

Personal injury. Load should be properly placed & supported to

Collied with avoid fall.

existing panels. Pump will be lifting & shifting in systematic &

planned manner to avoid falling, tilt or slipping

from chain block.

5. Fastening of Pinch point. Keep fingers and hand away from pinch point.

Nuts & Personal injury Never put hand and finger under or in between bolt.

Bolts Use proper tools for alignment.

6. Grouting Un-inspected use Before use drill machines must be inspected by a

of drill machines. concerned electrical engineer.

Improper PPE's Prior to work all PPE's must be inspected.

of workers. Prior to work all participants must be aware about

Grouting work MSDS.

start without

MSDS.

0 Mr. ABIN Mr. SUDHI P Mr. BIPIN V

JOSEPH

Rev Date Prepared By Checked By Reviewed By Reviewed By Approved By

(Site Engr. (HSE, (RCM, (TPIL Engr.,) (BPCL)

Contractor) Contractor) Contractor)

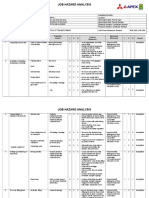

General precaution for Demolition:

1) Instruction should be given for “NO SMOKING” and ensure that no fire/ hot

work occurs nearby.

Page | 4

� 2) Tools & nails are to be kept in a toolbox never carry the nails in bags or in

pockets.

3) Materials shall be kept in arrange way on the ground. The foreman shall ensure

good housekeeping.

4) Tie the lifeline while making beam bottom at the outer side.

5) Support the lifeline at every 5 m length.

6) Helpers should not be allowed to work at outer side.

7) Ensure access wherever you work.

8) Check for defective tools.

9) The included angle for the ladder is 75 degree and the ladder should extend at

least 1 m beyond the landing platform.

10) The ladder must be secured at the top and bottom. Do not use top rung or top step

of the ladder.

11) Never use brittle materials like brick as a packing material.

12) Do barricading/Identified/highlight while doing breaking work at outer side.

13) While demolition keep one helper to remove the nails and stack the shutters

properly (neatly) and ensure proper access.

14) 1/3 of portion of the tower only can be projected beyond periphery of the slab as

cantilever.

15) In such cases the Wallers to be secured by hooks embedded in concrete.

16) Props used at periphery must be braced adequately.

17) Barricade stored material properly.

18) Use proper PPE's

Page | 5