100% found this document useful (2 votes)

2K views37 pagesSperre Air Compressor

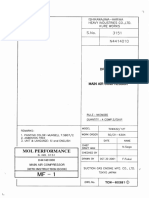

This document provides specifications for equipment used on a ship's main air compressor system. It includes:

- Details on two main air compressors that are model HL2/160.

- Specifications for additional air compressors, valves, switches, and other components that make up the air compressor system.

- Drawings and part numbers for each component, including dimensions, materials, electrical information, and performance specs.

- Contact information for the supplier, Sperre Industri AS, for genuine spare parts.

Uploaded by

RK PanchalCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

2K views37 pagesSperre Air Compressor

This document provides specifications for equipment used on a ship's main air compressor system. It includes:

- Details on two main air compressors that are model HL2/160.

- Specifications for additional air compressors, valves, switches, and other components that make up the air compressor system.

- Drawings and part numbers for each component, including dimensions, materials, electrical information, and performance specs.

- Contact information for the supplier, Sperre Industri AS, for genuine spare parts.

Uploaded by

RK PanchalCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 37