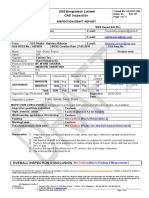

Yunusco (BD) Limited: Flow Chart For Sewing

Uploaded by

Md. Nurunnabi SarkerYunusco (BD) Limited: Flow Chart For Sewing

Uploaded by

Md. Nurunnabi SarkerYunusco (bd) Limited

FLOW CHART FOR SEWING

Reference: YBD-QA-PROC-FC-2.4-002

Start PP Meeting

Pilot cut sample making:

1. Pilot cut sample making should be done prior to bulk production. This represents all sizes to

Received check quality/standared requirment of buyer.

cut panel/Trims 2. Pilot cut sample should be made as per actual fabric, trimes & accessories.

/Accessories 3. Production, QAD team, Maintanance Dept should be present during pilot cut sample making

to ensure that all problems encountered during sewing will be noted and have proper

corrective action if needed.

4. Pilot cut sample should be eveluated for quality, measurement and check of all stitching is as

per technical package.

5. Mechanic to prepare all the folders, attachments requiered prior to sewing of pilot cut

sample.

Check/Count

In line QC:

1. Check first sewing output evaluation.

2. Panel check on measurement sheet.

3. Prepare mock-up sample for all operation & attached to the machine.

4. Check critical operation hang on the machine.

5. Follow traffic light system in checking operator's performance.

Document Receiving

Pre-prodection Meeting:

1. Pre-production meeting should be conducted prior to bulk prodection in order to identify

problems & review buyer's comments on sample.

2. Review production capacity , time & action clander.

3. check status of fabric, trims & accessories availablity.

4. Review pattern againrst buyer sample.

5. Review wash standared if any

6. This meeting should be attended by: Merchandider, Technical (sample co-ordinator),

Get pattern Planning, work, stady, production, Mechanic, Quality assurance & Buyer representative if

available.

Sewing

Traffic light system: Spot Put in box Send to spot remove area

1. Inline QC check each & every operation, per operator min of 4

times per day.

2. Out of every operation, 7 pices are rendomly pick & check. Inspect garments

3. Every defect found is described by standared coding system. 100% for

4. Inline QC fold the garments with defect & filled up the report. Alter Put in alter/defect box Return to sewing for rectify

5. Green, Yellow & Red cards are issued to show the result if workmanship &

inspection done. measurment

Defect Reject Put in rejected box Review by QAD & make challan/

deliver to store.

Zero defect

1 Defect

2 Defect or more Good

Consecutive 1 defect- 3rd hour will be red card.

Consecutive 2 or more defect- red card and machine has to stop

on second hour.

6. Traffec light report with root cause & action plan should be Document all reports

hang on every operator/ machine.

7. Supervisor to review & analyze the defect & make action plan

for improvement.

Fail

Pre-AQL 100% rescreen by Line Qc/

1.5 End Table Qc

End line QC check:

Pass 1. Check all finished bundle 100% for workmanship and measurement.

2. End line QC table should have the folling documents attached on the table.

a)Technical file b) pp meeting comments c) Approved

referance sample d) Trim card e) Standared defect code

f) Buyer's comments g) Measurement sheet h) Inspection

Send to Finishing method

3. Garments found with defect/reject should be placed on designated box

Good garments

Alter

Reject

END 4. End line QC inspect garments following clockwise system. Put arrow

sticker on all defects/ rejects found.

5. Defects are discribed by standared coding system.

6. Documents all findings.