0% found this document useful (0 votes)

106 views8 pagesResponsabilities API 510

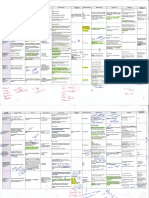

This document outlines the responsibilities for complying with API 510 standards for various activities related to pressure vessel inspection, testing, and repair. It assigns ownership of each activity to either the authorized inspector, engineering department, or owner organization. Key responsibilities include overall compliance with API 510 (owner), approving inspection methods and results (inspector, engineering), authorizing repairs, alterations and welding (inspector, engineering), and reviewing alternative inspection methods or extended inspection intervals (engineering).

Uploaded by

kataCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

106 views8 pagesResponsabilities API 510

This document outlines the responsibilities for complying with API 510 standards for various activities related to pressure vessel inspection, testing, and repair. It assigns ownership of each activity to either the authorized inspector, engineering department, or owner organization. Key responsibilities include overall compliance with API 510 (owner), approving inspection methods and results (inspector, engineering), authorizing repairs, alterations and welding (inspector, engineering), and reviewing alternative inspection methods or extended inspection intervals (engineering).

Uploaded by

kataCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

/ 8