0% found this document useful (0 votes)

864 views12 pagesHeader Design

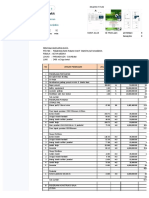

The document provides design calculations for steam piping components. It calculates the diameter and thickness of an off-take pipe and main steam header given specifications for steam flow rate and pressure. It then selects pipe sizes and materials according to standards. Component selections include a flowmeter, strainer, and thermodynamic steam trap. A system layout diagram shows the arrangement of these components.

Uploaded by

Gun SmithCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

864 views12 pagesHeader Design

The document provides design calculations for steam piping components. It calculates the diameter and thickness of an off-take pipe and main steam header given specifications for steam flow rate and pressure. It then selects pipe sizes and materials according to standards. Component selections include a flowmeter, strainer, and thermodynamic steam trap. A system layout diagram shows the arrangement of these components.

Uploaded by

Gun SmithCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 12