0% found this document useful (0 votes)

182 views26 pagesSources for Process Improvement

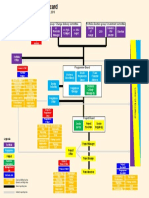

The document discusses sources for continuous process improvement projects. It outlines four main steps in continuous improvement and lists various internal and external sources that can provide opportunities for improvement projects, including strategic priorities, industry trends, performance issues, audit findings, process mining, customer feedback, and benchmarking. Case studies are also presented on sources of improvements for specific operating companies. The overall goal is to inspire the identification of improvement opportunities and learn from each other.

Uploaded by

pascal mubalamaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

182 views26 pagesSources for Process Improvement

The document discusses sources for continuous process improvement projects. It outlines four main steps in continuous improvement and lists various internal and external sources that can provide opportunities for improvement projects, including strategic priorities, industry trends, performance issues, audit findings, process mining, customer feedback, and benchmarking. Case studies are also presented on sources of improvements for specific operating companies. The overall goal is to inspire the identification of improvement opportunities and learn from each other.

Uploaded by

pascal mubalamaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 26